During the extrusion process of aluminum plates, surface peeling or bubbles are likely to occur. What is the reason for this? What method should be used to eliminate it? Now let the aluminum plate manufacturer help you troubleshoot and clarify any issues!

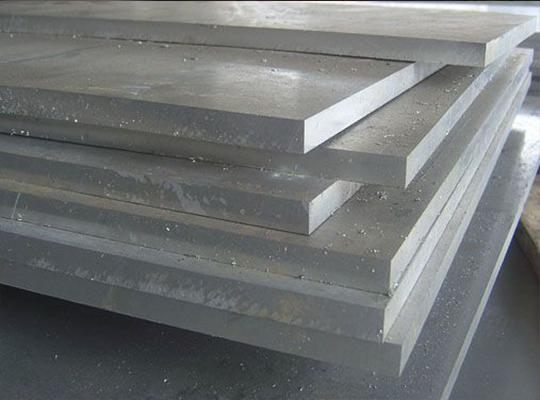

What is bubble or peeling: convex bubbles appear on the surface of a product, commonly found at the head and tail. The intact ones are called bubbles, and the ones that have broken are called peeling.

The causes of bubbles and peeling during aluminum plate extrusion

1. The wear of the extrusion cylinder and extrusion pad exceeds the tolerance, and the size matching of the extrusion cylinder and extrusion pad is improper. The diameter difference of the gasket used exceeds the allowable value;

2. The extrusion cylinder and extrusion pad are too dirty, with oil stains, moisture, graphite, etc. stuck;

3. Lubricating oil contains water;

4. There are too many grooves on the surface of the ingot, which are too deep, or there are pores, sand holes, loose tissue, and oil stains on the surface of the ingot;

5. When replacing the alloy, the inside of the cylinder is not cleaned thoroughly;

6. The temperature of the extrusion cylinder and the temperature of the extrusion ingot are too high;

7. The temperature and size of the ingot exceed the allowable negative deviation;

8. The ingot is too long, filled too quickly, and the temperature of the ingot is uneven, causing non bulging filling, resulting in incomplete exhaust in the cylinder or improper operation, and the exhaust process is not executed;

9. The design of the mold hole is unreasonable, or the cutting of the residue is improper. The residue in the diversion hole and guide hole is partially carried out, and the gas in the gap enters the surface during compression.

Methods for eliminating bubbles and peeling caused by aluminum plate extrusion

1. Reasonably design the fitting size of the extrusion cylinder and the extrusion gasket, regularly check the tool size to ensure compliance with requirements. If there is a large belly in the extrusion cylinder, it should be repaired in a timely manner, and the extrusion gasket should not exceed the tolerance;

2. Keep the surface of tools and ingots clean, smooth, and dry;

3. When replacing the alloy, thoroughly clean the cylinder;

4. Regularly inspect equipment and instruments to prevent excessive temperature and speed;

5. Strictly implement the process regulations and various systems;

6. Reasonably design and manufacture molds, with guide holes and diversion holes designed with an internal slope of 1 ° -3 °;

Strict operation, correct cutting of residues and complete exhaust.

Through expert Q&A, I believe everyone has a deep understanding of the causes and elimination methods of bubbles and peeling during aluminum plate extrusion. Avoiding these problems in daily production can reduce losses and improve product yield.