What is Aluminum Temper?

Aluminum temper refers to the condition of aluminum alloy as a result of thermal processing or mechanical treatment. The temper designation is a letter or number code that signifies the specific condition of the material. The temper designation is used to indicate the hardness, strength, or ductility of the aluminum alloy after treatment. Understanding aluminum temper is crucial for selecting the right material properties and optimizing manufacturing processes, ensuring efficient designs, reliable products, and compliance with industry standards. It empowers individuals to make informed decisions and achieve desired mechanical performance in aluminum applications.

Aluminum Temper F

Overview

In the case of temper F, it typically indicates a solution heat-treated and then artificially aged condition. The F temper is commonly associated with precipitation-hardened aluminum alloys, such as those from the 2000 and 7000 series.

Properties of Aluminum Temper F

- Strength: Aluminum alloys treated to the F temper exhibit increased strength due to the precipitation of fine particles within the metal matrix.

- Hardness: The F temper provides improved hardness compared to the annealed or as-cast state of aluminum alloys.

- Machinability: While the hardness is increased, the machinability of aluminum alloys in the F temper may be slightly reduced compared to softer conditions.

- Weldability: Aluminum alloys in the F temper generally maintain good weldability, although specific alloys may have varying responses to welding processes.

Uses of Aluminum Temper F

- Aerospace Applications: Aluminum alloys in the F temper are commonly used in aerospace industries for structural components, such as aircraft wings, fuselages, and landing gear, where high strength-to-weight ratio is crucial.

- Automotive Industry: Certain aluminum alloys treated to the F temper are utilized in the automotive industry for applications like engine components, suspension parts, and wheels, where strength and weight reduction are desirable.

Aluminum Temper O

Overview

Aluminum temper O refers to the annealed condition of aluminum, where the material is fully softened through a process of heating and controlled cooling. The temper designation system is used to describe the thermal treatment or mechanical working that is applied to aluminum alloys to achieve desired properties.

Properties of Aluminum Temper O

- Softness: Aluminum alloys in the O temper are in their softest state. The material is highly ductile and easily formed or shaped.

- Low Strength: The O temper provides the lowest strength level among the temper designations. Aluminum alloys in this temper are not hardened or strengthened through heat treatment.

- High Electrical and Thermal Conductivity: Aluminum alloys in the O temper retain high electrical conductivity and thermal conductivity, making them suitable for applications that require these properties.

Uses of Aluminum Temper O

- General Fabrication: Aluminum alloys in the O temper are commonly used in general fabrication applications, such as sheet metal work, where formability and ease of manipulation are important.

- Cooking Utensils: The O temper is suitable for manufacturing cooking utensils, pots, pans, and other food preparation equipment due to its excellent formability and high thermal conductivity.

- Packaging: Aluminum foils and sheets in the O temper are widely used in packaging applications, including food packaging, pharmaceutical packaging, and beverage can manufacturing.

Aluminum Temper H

Overview

Aluminum temper H refers to a group of temper designations within the aluminum alloy system that indicate different levels of strain hardening or work hardening. The temper designation system is used to describe the thermal treatment or mechanical working that is applied to aluminum alloys to achieve desired properties. The H temper designation is followed by numbers (e.g., H1, H2, H3, etc.), with higher numbers indicating higher levels of strain hardening. Each H temper designation represents a specific combination of cold working and thermal treatment applied to the aluminum alloy.

Properties of Aluminum Temper H

- Increased Strength: Aluminum alloys in the H temper exhibit increased strength due to cold working or strain hardening. The higher the H number, the greater the strength achieved.

- Reduced Ductility: As the strength increases through strain hardening, the ductility or formability of the aluminum alloy decreases. Higher H numbers indicate reduced ductility.

- Enhanced Hardness: The H temper provides improved hardness compared to the annealed or as-cast state of aluminum alloys due to the work hardening process.

- Improved Mechanical Properties: Aluminum alloys in the H temper typically have improved mechanical properties, including higher yield strength and tensile strength.

Uses of Aluminum Temper H

- Structural Applications: Aluminum alloys in the H temper are commonly used in structural applications that require higher strength, such as aerospace components, automotive parts, and construction materials.

- Automotive Industry: H-tempered aluminum alloys find applications in the automotive industry for body panels, engine components, and suspension parts, where strength and weight reduction are important.

- Electrical Conductors: Certain aluminum alloys in the H temper are used as electrical conductors, such as bus bars and electrical connectors, due to their improved strength and electrical conductivity.

Aluminum Temper T

Overview

Aluminum temper T refers to a group of temper designations within the aluminum alloy system that indicate specific heat treatments applied to the material. The T temper designation is followed by one or more digits, which provide information about the specific thermal treatment processes used.

Properties of Aluminum Temper T

- Strength and Hardness: Aluminum alloys in the T temper exhibit increased strength and hardness due to the precipitation of alloying elements during the heat treatment process.

- Improved Mechanical Properties: The T temper generally results in improved mechanical properties, including higher yield strength, tensile strength, and hardness compared to the annealed or as-cast state.

- Retained Formability: While the T temper provides increased strength, the formability and ductility of aluminum alloys are generally well-preserved.

- Controlled Thermal Stability: The T temper involves a balance between heat treatment and natural aging processes to achieve the desired properties. This provides consistent and predictable material performance.

Uses of Aluminum Temper T

- Aerospace Applications: Aluminum alloys in the T temper are widely used in the aerospace industry for structural components, such as aircraft frames, wings, and landing gear, where high strength-to-weight ratio and fatigue resistance are critical.

- Industrial Equipment: Aluminum alloys in the T temper are employed in various industrial equipment and machinery, such as heat exchangers, pressure vessels, and conveyor systems, where a balance of strength, formability, and corrosion resistance is required.

- Sporting Goods: T-tempered aluminum alloys are used in the manufacturing of sporting goods, including bicycles, golf clubs, and tennis rackets, to provide lightweight yet strong and durable products.

- Architectural Applications: Aluminum alloys in the T temper are utilized in architectural applications, such as window frames, curtain walls, and structural components, where strength, corrosion resistance, and design flexibility are important.

Common Aluminum Alloys Types

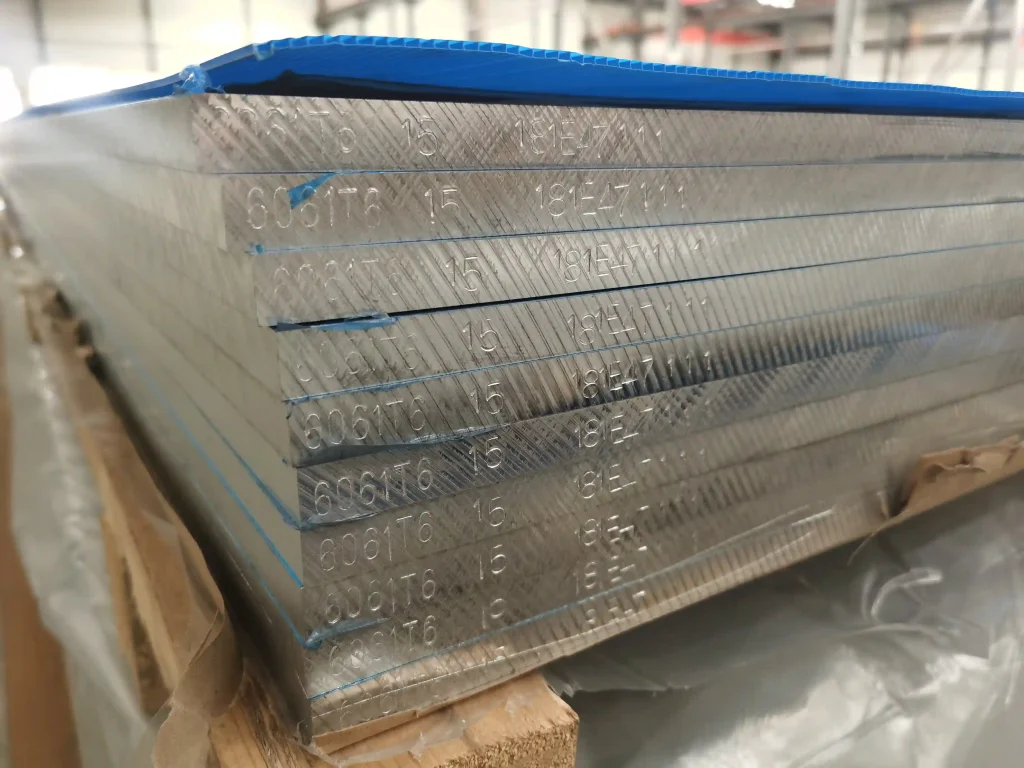

Aluminum Alloy 6061

- 6061 T6: Solution Heat Treated and Artificially Aged

- 6061 T651: Solution Heat Treated, Stress Relieved by Stretching, and Artificially Aged

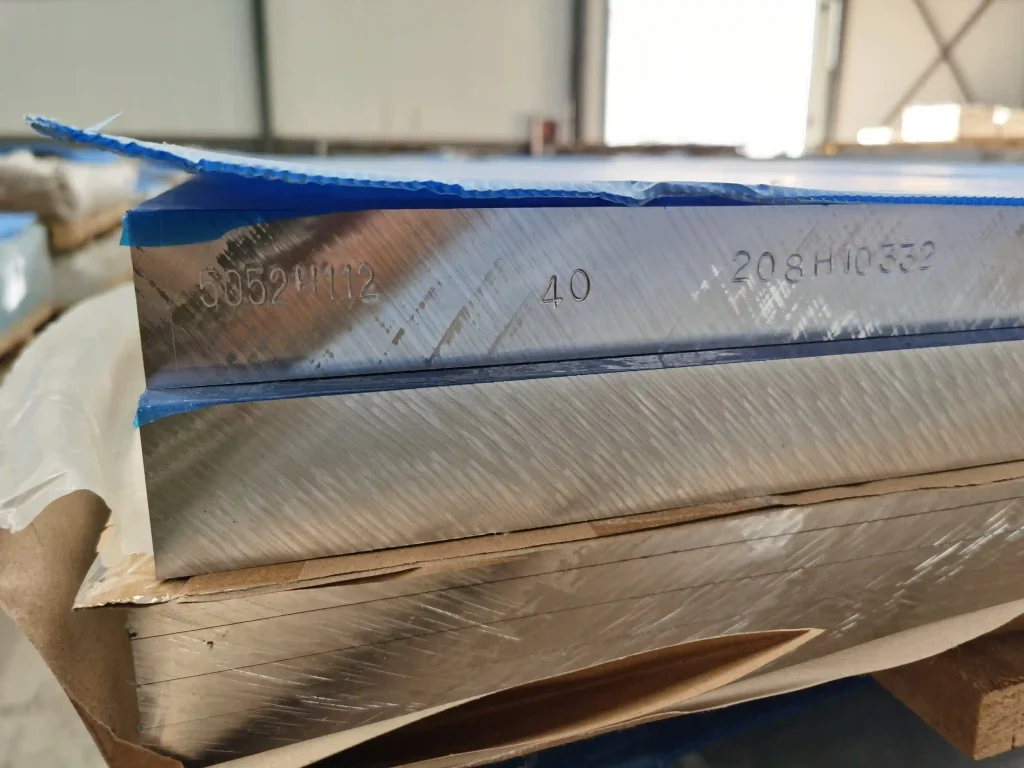

Aluminum Alloy 5052

- 5052 H32: Strain Hardened and Stabilized

- 5052 H34: Strain Hardened and Stabilized, then Naturally Aged

Aluminum Alloy 3003

- 3003 H14: Strain Hardened

- 3003 H24: Strain Hardened and Partially Annealed

Aluminum Alloy 7075

- 7075 T6: Solution Heat Treated and Artificially Aged

- 7075 T651: Solution Heat Treated, Stress Relieved by Stretching, and Artificially Aged

Aluminum Alloy 2024

- 2024 T3: Solution Heat Treated and Cold Worked

- 2024 T351: Solution Heat Treated, Stress Relieved by Stretching, and Cold Worked

Features Comparison of Different Aluminum Temper types

Formability and Workability

- F Temper: Offers good formability and workability, making it suitable for various fabrication processes.

- O Temper: Provides maximum softness and ductility, allowing for extensive forming or bending.

Strength and Hardness

- H Temper: Achieved through strain hardening, it offers increased strength and hardness compared to the O temper.

- T Temper: Achieved through heat treatment, it provides enhanced strength, hardness, and dimensional stability.

Heat Treatment

- F Temper: Does not involve specific heat treatment.

- O Temper: Fully annealed, relieving internal stresses through heating and slow cooling.

- H Temper: Involves strain hardening through cold working.

- T Temper: Involves heat treatment processes like solution heat treatment and artificial aging.

Summary

In conclusion, the introduction to aluminum temper designations provides a comprehensive understanding of the various conditions and treatments applied to aluminum alloys. The temper designations play a crucial role in determining the mechanical properties, formability, strength, hardness, and other characteristics of aluminum. Understanding aluminum temper designations is essential for selecting the appropriate alloy and temper for specific applications, ensuring optimal performance and desired characteristics in various industries.

FAQ

What is the difference between temper T6 and T62?

The difference between temper T6 and T62 lies in the specific aluminum alloys they are applied to and the parameters used during the heat treatment process, but both temper designations result in high-strength properties for their respective alloys.

What is T7451 temper?

The T7451 temper is a stress-relieved temper for aluminum alloy 7075, achieved through solution heat treatment, quenching, artificial aging, and stress relief stretching, offering high strength, good stress corrosion cracking resistance, and improved machinability.

What is the difference between H32 and H34 temper?

The H32 and H34 tempers are strain-hardened and stabilized tempers for aluminum alloys, with H32 providing moderate strength and good formability, while H34 offers higher strength due to a greater degree of strain hardening.

What is 7050 T7451 standard?

The 7050 T7451 standard specifies the requirements for aluminum alloy 7050 in the T7451 temper, ensuring consistent heat treatment, mechanical properties, and other characteristics such as strength, stress corrosion cracking resistance, and machinability for this specific alloy and temper combination.