Plastic films are often used in life. What materials are these plastic films made of? What are their performance characteristics? Plastic films are made of polyvinyl chloride, polyethylene, polypropylene, polystyrene, and other resins, used for packaging and as a coating layer. Plastic film refers to a plastic product with a certain thickness (thickness is 0.01~0.25 mm), width, and unlimited length, with a flat surface, smooth and soft, which is made of polymer synthetic materials as the main raw materials, evenly mixed with other auxiliary raw materials in a certain proportion, and then formed on plastic molding machinery and equipment.

Plastic films can be divided into industrial plastic films and packaging plastic films according to their uses. The following are the 7 most commonly used plastic films in industry and life:

Bopp Film

Bopp film is a transparent, flexible packaging material. It uses a special production line to mix polypropylene raw materials and functional additives, melt and mix them, make sheets, and then stretch them into films.

BOPP film not only has the original advantages of PP film, such as low density, good corrosion resistance, and good heat resistance, but also has good optical properties, high mechanical strength, and abundant raw material sources. It is widely used in the packaging of food, candy, cigarettes, tea, juice, milk, textiles, etc., and is known as the “Queen of Packaging.”.

In addition, it can also be used to prepare high-value-added functional products such as electrical films and microporous films.

BOPP film can be compounded with other materials with special properties to further improve or improve performance. Commonly used materials include PE film, cast polypropylene (CPP) film, polyvinylidene chloride (PVDC), aluminum foil film, etc.

Cpp Film

CPP film is a non-stretched, non-directional flat extruded film produced by melt casting and quenching. It is characterized by fast production speed, high output, good film transparency, glossiness, thickness uniformity, and excellent balance of various properties. Since it is a flat extruded film, subsequent work such as printing and lamination is extremely convenient. CPP is widely used in the packaging of textiles, flowers, food, and daily necessities.

PET Film

PET film is a thermoplastic plastic film, which is made into thick sheets by extrusion and then made into a film material by biaxial stretching. The characteristics of polyester film are excellent mechanical properties, high rigidity, hardness and toughness, puncture resistance, friction resistance, high and low temperature resistance, chemical resistance, oil resistance, good air tightness, and fragrance retention. It is one of the commonly used barrier laminated film materials.

Polyester film is relatively expensive, with a thickness of generally 0.12 mm. It is often used as the outer layer material of food packaging and has good printability. In addition, polyester film is often used as printing and packaging consumables such as environmentally friendly film, PET film, and milky white film and is widely used in fiberglass, building materials, printing, medicine, and health industries.

PVA Film

The density of PVA film is 1.26–1.29 g/cm3, the refractive index is 1.52, and it emits blue-white light after ultraviolet irradiation. It has high water absorption and can dissolve in water.

It can pass water vapor, and the barrier property of polyvinyl alcohol film is even better than that of vinylidene chloride film. PVA is the only vinyl polymer that can be used by bacteria as a carbon source and energy source. Under the action of bacteria and enzymes, it can be degraded by 75% in 46 days. It is a biodegradable polymer material that can be mass-produced by non-petroleum routes at a low price. It has outstanding oil resistance, solvent resistance, and gas barrier properties and has unique advantages in food and drug packaging.

PVA film is prepared by casting film, but solution processing and molding require dissolution and drying processes. At the same time, it cannot be co-extruded with other materials to prepare multi-layer composite films. Polyvinyl alcohol is non-toxic, odorless, and harmless to the human body. It has good affinity with the natural environment, does not accumulate, and does not pollute.

LDPE Film

LDPE film, also called PE film, has the characteristics of moisture resistance and low moisture permeability. It is a synthetic ethylene resin under high pressure, so it is also called “high-pressure polyethylene”. PE film has low density, softness, low temperature resistance, impact resistance, good chemical stability and corrosion resistance. LDPE film is translucent, glossy, heat-sealable, water-resistant and boilable. Its main disadvantage is its poor barrier to oxygen.

It is often used as the inner film of composite flexible packaging materials, and it is also the most widely used and largest plastic packaging film. PE packaging film is the main material for food packaging. Secondly, polyethylene film is also used in the field of civil engineering, such as geomembrane. It can play a waterproof role in civil engineering and has extremely low permeability. Agricultural film is used in agriculture, which can be divided into greenhouse film, ground film, bitter cover film, silage film, etc.

PA Film

Nylon plastic film (ONY) is also called PA. There are many varieties of nylon currently produced industrially, among which the main varieties used to produce films are nylon 6, nylon 12, nylon 66, etc.

Nylon film is a very tough film with good transparency and good gloss, high tensile strength and tensile strength, good heat resistance, cold resistance, oil resistance, and is relatively soft. It has excellent oxygen barrier properties but poor barrier properties to water vapor, high moisture absorption and moisture permeability, and poor heat sealing properties. It is suitable for packaging hard items, such as greasy foods, meat products, fried foods, vacuum-packed foods, steamed foods, etc.

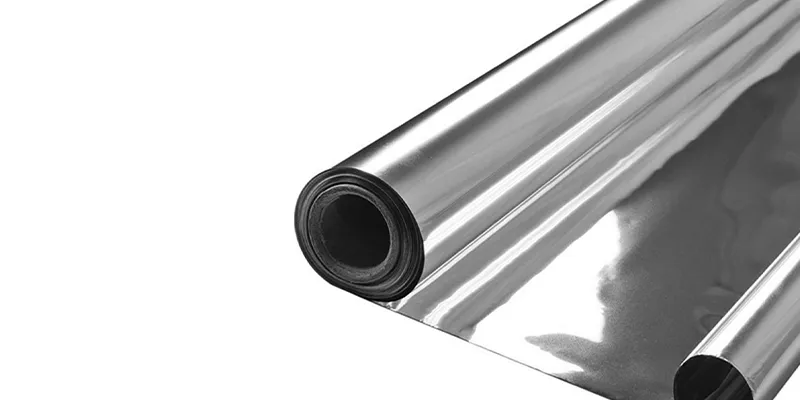

Aluminized Plastic Film

Aluminized film has the characteristics of both plastic film and metal. The function of aluminum plating on the surface of the film is to block light and prevent ultraviolet radiation, which not only prolongs the shelf life of the contents but also improves the brightness of the film. It replaces aluminum foil to a certain extent and is also cheap, beautiful, and has good barrier properties. Therefore, aluminized film is widely used in composite packaging, mainly used in the packaging of dry and puffed foods such as biscuits, as well as the outer packaging of some medicines and cosmetics.