Coated aluminum foil is highly valued for its unique properties and wide range of applications. As an essential material, it plays an irreplaceable role in sectors such as food packaging, electrical insulation, and industrial applications. This article delves into the numerous advantages of coated aluminum foil to help you understand its value.

Excellent Corrosion Resistance of Coated Aluminum

The surface of coated aluminum foil undergoes special treatment that provides exceptional corrosion resistance. This protective coating effectively prevents moisture and oxygen from penetrating, making it particularly important in food packaging. It helps maintain food freshness and hygiene, preventing oxidation and spoilage. Additionally, in the packaging of chemicals, this corrosion resistance ensures product safety and stability.

Strong Barrier Properties

Coated aluminum foil boasts excellent barrier properties against gases and water vapor. Its unique structure prevents the permeation of oxygen and moisture, keeping the internal environment of the packaging stable. This characteristic makes it ideal for food and pharmaceutical packaging, significantly extending product shelf life. For instance, when packaging liquid foods and perishable goods, coated aluminum foil can shield them from external factors, preserving their taste and nutritional content.

Superior Thermal Conductivity of Coated Aluminum Foil

The thermal conductivity of aluminum is crucial for applications in various electronic products, and coated aluminum foil is no exception. Due to heat generation during operation, effective heat dissipation is essential to avoid overheating and ensure safe and stable operation. Coated foil, with its large surface area, dissipates heat efficiently, prolonging the lifespan of devices, like motors and transformers, by reducing the risk of failure.

Ease of Processing and Forming

Coated foil exhibits excellent machinability, making it easy to cut, shape, and weld. This adaptability allows for flexibility in industrial production, meeting both large-scale manufacturing and small-batch customization needs. Whether creating complex packaging shapes or building electrical insulation layers, coated aluminum foil can easily adapt, enhancing production efficiency.

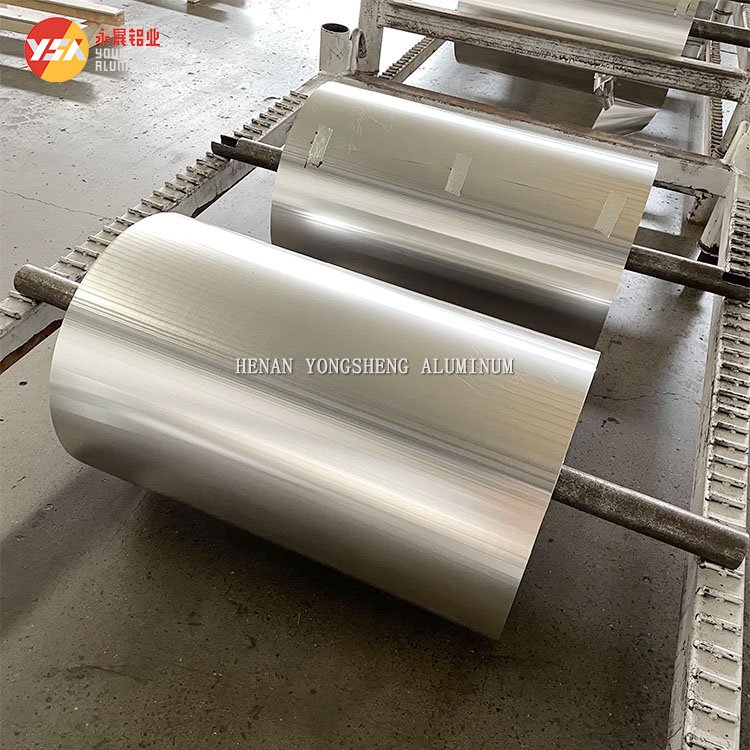

Attractive Aesthetic Appeal of Coated Aluminum

In addition to its functional advantages, coated aluminum foil features a smooth, glossy surface that enhances the visual appeal of products. In sectors like food packaging and gift wrapping, using coated foil can elevate the overall aesthetic quality, attracting consumer attention. Given that consumers place high value on product appearance, coated aluminum foil can significantly add to brand image and marketing strategies.

Environmental Friendliness and Recyclability

In today’s world, environmental considerations are increasingly important, and aluminum is a recyclable material. The use of coated aluminum not only meets these environmental standards but also aligns with sustainable development goals. By promoting recycling and reuse, it significantly reduces resource waste and environmental pollution. This eco-friendly aspect increasingly appeals to consumers, making coated aluminum foil a standout choice in modern packaging materials.

Versatile Applications of Coated Aluminum

Coated aluminum is multifunctional and widely used across various industries. It is not only critical in food and pharmaceutical packaging but also serves important roles in electrical insulation, construction materials, and transportation. For example, in the construction industry, coated aluminum foil can be used for roofing and wall insulation, improving a building’s energy efficiency. In transportation, its lightweight and durable nature protects goods during transit.

Conclusão

In summary, coated aluminum foil’s exceptional corrosion resistance, barrier properties, thermal conductivity, ease of processing, and aesthetic appeal make it an ideal choice across multiple industries. Its eco-friendliness and recyclability further enhance its competitive edge in today’s market. As technology continues to advance, the applications of coated foil will expand even further, driving innovation and enhancing product quality. Whether in protecting food, maintaining pharmaceutical efficacy, or ensuring the safety of electronic devices, coated aluminum foil will continue to shine brightly in its essential role.