In the realm of material selection for various applications, the debate between aluminum alloy vs steel often arises when it comes to determining which material is stronger. Strength is a fundamental property that impacts the structural integrity and performance of a wide range of products. In this comprehensive blog, we will explore the concept of strength, delve into the methods used to measure it, and conduct a detailed comparison between aluminum alloy vs steel to determine which material truly reigns supreme in terms of strength.

What is Strength?

- Defining Strength: Strength refers to the ability of a material to withstand external forces without deformation or failure. It is a critical property for structures where load-bearing capacity and durability are paramount.

- Types of Strength: There are various types of strength, including tensile strength, compressive strength, shear strength, flexural strength, and yield strength. Each type represents the material’s ability to withstand specific types of forces and stresses.

How to Measure Strength?

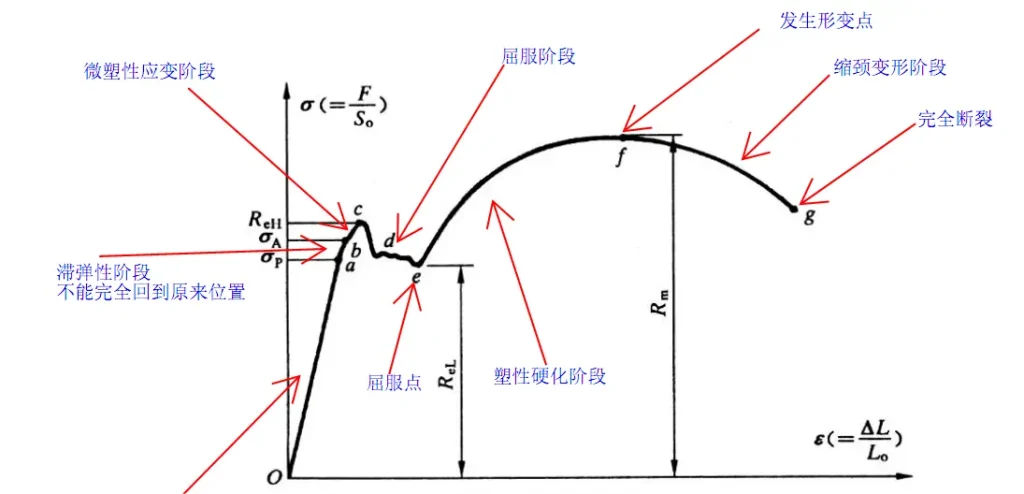

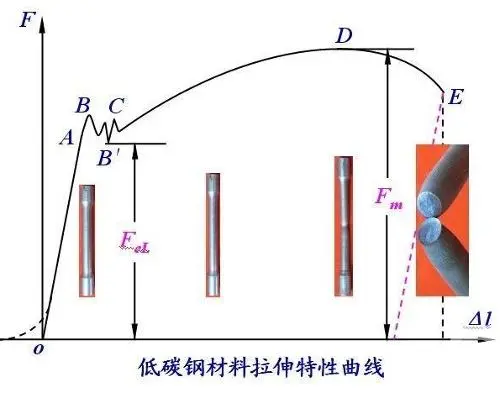

- Tensile Strength: Tensile strength is a key parameter used to measure a material’s ability to resist pulling forces or tension. It is determined by subjecting a material sample to tension until it reaches its breaking point.

- Compressive Strength: Compressive strength measures a material’s resistance to crushing or compression forces. It is determined by applying compressive loads to a material sample until it fails.

- Shear Strength: Shear strength represents a material’s resistance to forces that cause one part of the material to slide or deform relative to another part in parallel planes.

- Flexural Strength: Flexural strength is the ability of a material to resist bending or breaking under applied loads. It is commonly assessed in materials used for beams and structural components.

- Yield Strength: Yield strength indicates the point at which a material begins to exhibit permanent deformation under applied stress.

Aluminum Alloy VS Steel: A Strength Comparison

- Aluminum Alloy vs Steel Tensile Strength: Steel generally exhibits higher tensile strength compared to aluminum alloy. Steel’s molecular structure and higher density contribute to its superior ability to withstand pulling forces.

- Aluminum Alloy vs Steel Compressive Strength: Steel also tends to have higher compressive strength than aluminum alloy. Its crystalline structure and higher stiffness make it more resistant to crushing forces.

- Aluminum Alloy vs Steel Shear Strength: Steel typically demonstrates higher shear strength than aluminum alloy. The strong atomic bonding in steel allows it to withstand shearing forces more effectively.

- Aluminum Alloy vs Steel Flexural Strength: Steel’s inherent strength and rigidity give it an advantage in terms of flexural strength, making it suitable for applications requiring resistance to bending or deflection.

- Aluminum Alloy vs Steel Yield Strength: Steel generally has a higher yield strength than aluminum alloy, meaning it can withstand greater stress before permanent deformation occurs.

Factors Influencing Strength

Alloy Composition

The specific composition of an aluminum alloy or steel can significantly impact its strength properties. Alloying elements and heat treatment processes can enhance strength characteristics. Here are some commonly used aluminum alloy series known for their strength:

- 2000 Series Aluminum Alloy: Aluminum-copper alloys. They have excellent strength, particularly when heat-treated. Examples include 2024 and 2014 alloys, which are widely used in aerospace applications.

- 6000 Series Aluminum Alloy: Aluminum-magnesium-silicon alloys. This series offers good strength and corrosion resistance. The most well-known alloy in this series is 6061, which is widely used in various structural applications.

- 7000 Series Aluminum Alloy: Aluminum-zinc-magnesium alloys. These alloys have exceptional strength and are often used in high-stress applications, such as aerospace components. The most common alloy in this series is 7075, renowned for its high strength-to-weight ratio.

- 5000 Series Aluminum Alloy: Aluminum-magnesium alloys. While not as strong as the 2000 and 7000 series, they still offer good strength and excellent corrosion resistance. The 5052 and 5083 alloys in this series are frequently used in marine and automotive applications.

- 8000 Series Aluminum Alloy: Aluminum-lithium alloys. These alloys combine high strength with low density, making them attractive for aerospace applications where weight reduction is crucial. Alloys such as 8090 and 2099 belong to this series.

Manufacturing Processes

The manufacturing processes used to shape and form aluminum alloy vs steel can affect their final strength. Processes like extrusion, rolling, forging, and heat treatment can influence the material’s microstructure and, consequently, its strength.

Tratamento térmico

Heat treatment techniques, such as quenching and tempering, can be employed to enhance the strength of both aluminum alloy and steel. Heat treatment alters the material’s internal structure, improving its strength properties.

| Strength Category | Liga de alumínio | Steel |

| Resistência à tração | Moderate to High | Elevado |

| Compressive Strength | Moderate | Elevado |

| Flexural Strength | Moderate to High | Elevado |

| Resistência ao escoamento | Moderate to High | Elevado |

| Alloy Composition | Aluminum, various alloying elements (e.g., copper, magnesium, zinc) | Iron, carbon, various alloying elements (e.g., chromium, nickel) |

| Manufacturing Processes | Casting, extrusion, rolling, forging | Casting, hot rolling, cold rolling, forging |

| Tratamento térmico | Annealing, solution heat treatment, precipitation hardening | Annealing, quenching, tempering |

Aluminum Vs Steel: Strength-to-Weight Ratio

- Liga de alumínio: Aluminum alloys offer a superior strength-to-weight ratio compared to steel. Their low density makes them exceptionally lightweight while maintaining satisfactory strength, making them ideal for applications where weight reduction is crucial.

- Steel: Steel, although denser than aluminum alloy, boasts remarkable strength-to-weight characteristics. While it may not match the lightweight nature of aluminum alloys, steel provides unparalleled strength in applications that require high load-bearing capacity and rigidity.

Cost:Aluminum Alloy VS Steel

When comparing the cost of aluminum alloy vs steel, several factors come into play, including the specific grade of the material, market conditions, and the quantity being purchased. However, in general, here are some key points to consider regarding the cost comparison between aluminum alloy vs steel:

- Raw Material Cost: The cost of raw materials can vary depending on the specific alloy and grade. Generally, aluminum alloy tends to have a higher cost per unit weight compared to steel. This is primarily due to the higher cost of refining and processing aluminum compared to iron and steel production.

- Manufacturing Processes: The manufacturing processes for aluminum alloy and steel can also affect the overall cost. For example, aluminum alloy typically requires more specialized and energy-intensive processes such as casting, extrusion, and heat treatment, which can contribute to higher production costs compared to certain steel manufacturing processes.

- Market Demand and Availability: Market demand and availability can influence the cost of both aluminum alloy and steel. If there is high demand for a particular material, its price may increase. Additionally, fluctuations in the availability and supply of raw materials can impact the cost of both aluminum alloy and steel.

- Application-Specific Cost Considerations: The specific application and requirements of a project or product can also impact the cost comparison. For certain applications, the benefits of using aluminum alloy, such as its lighter weight and corrosion resistance, may outweigh the higher material cost.

Application Considerations

- Liga de alumínio: Aluminum alloys find extensive use in aerospace, automotive, and construction industries, among others. Their strength, combined with excellent corrosion resistance and formability, makes them an ideal choice for lightweight structures and components.

- Steel: Steel is widely utilized in applications such as infrastructure, heavy machinery, and construction. Its exceptional strength, durability, and ability to withstand heavy loads make it indispensable in projects where structural integrity is paramount.

Resumo

Determining which material, aluminum alloy vs steel, is stronger requires a multifaceted analysis of their various strength properties. While steel generally exhibits higher tensile, compressive, shear, and flexural strength, aluminum alloys offer a remarkable strength-to-weight ratio. Factors such as alloy composition, manufacturing processes, and heat treatment techniques significantly influence the strength characteristics of both materials.

Ultimately, the choice between aluminum alloy and steel depends on the specific requirements of the application, including load-bearing capacity, weight considerations, environmental factors, and cost. It is essential to evaluate all relevant aspects and consult with experts to make an informed decision that ensures optimal strength and performanceof the final product or structure.