Mirror aluminum is a high brightness and extremely smooth aluminum product made through multiple processes such as surface treatment, polishing, and electrolysis. The production process roughly includes the following steps:

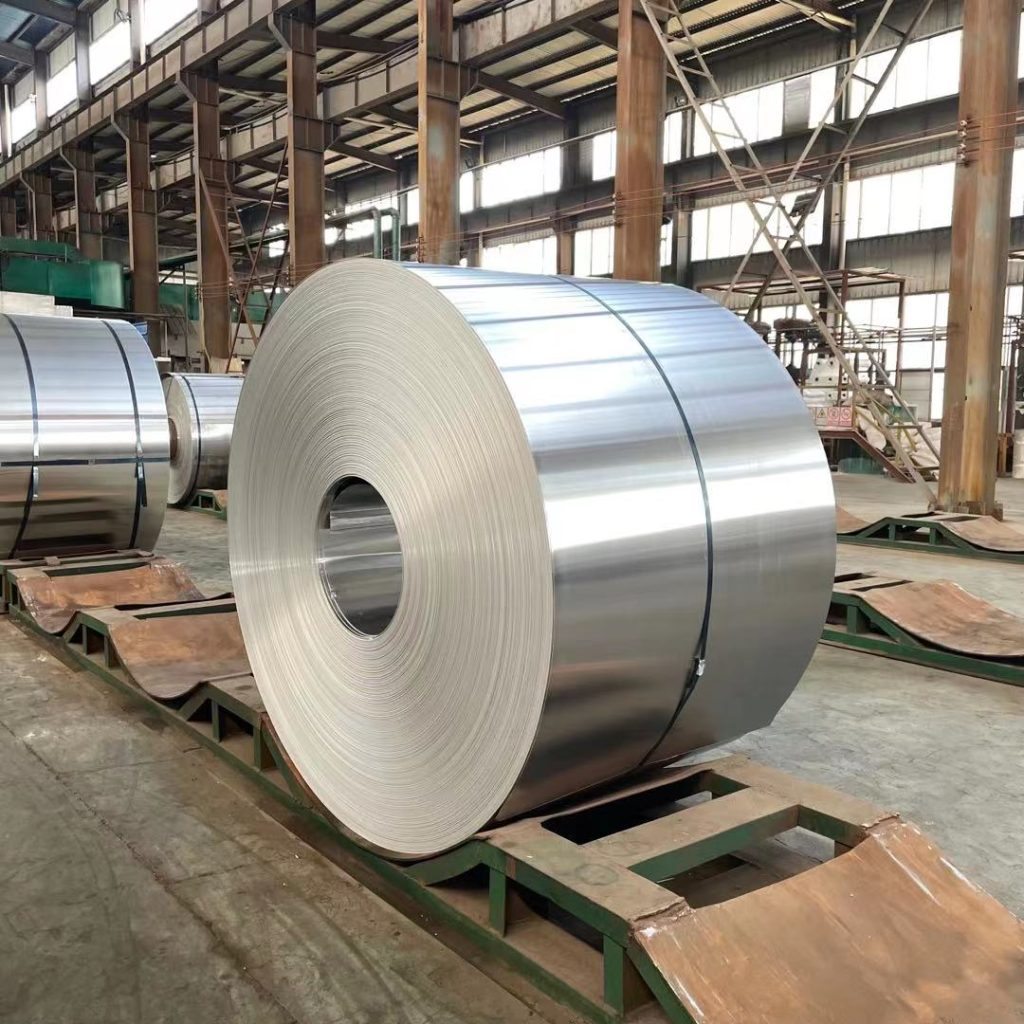

1. Aluminum material selection: Mirror aluminum is generally made of high-purity, impurity free aluminum plates or aluminum coils.

2. Surface treatment: Use chemical or mechanical methods to remove impurities, oxide scales, etc. from the surface of aluminum materials to ensure subsequent polishing and electrolytic treatment effects.

3. Mechanical polishing: Mechanical polishing is applied to aluminum materials to repair surface irregularities and scratches, resulting in a higher surface smoothness.

4. Electrolytic polishing: Immerse aluminum material in electrolyte for electrolytic polishing to make its surface smoother.

5. Electrochemical anodizing: Immerse aluminum into an electrolytic cell for electrochemical anodizing treatment to form a layer of aluminum oxide film, increase surface hardness, and improve surface corrosion resistance.

6. Cleaning and drying: Clean and dry the processed aluminum material to remove impurities such as residual electrolyte and moisture, ensuring the surface quality of mirror aluminum.

7. Hardness test: Conduct a hardness test on mirror aluminum to determine if its surface hardness meets the requirements.

The above is the basic process flow for producing mirror aluminum, and each step requires precise operation and strict control to ensure the surface smoothness and hardness requirements of the aluminum material.