Air conditioning aluminum foil is a critical material used extensively in heat exchangers of air conditioning systems. It possesses excellent thermal conductivity, corrosion resistance, and processability, making it indispensable in the manufacturing of air conditioners. Depending on different requirements and applications, air conditioning aluminum foil can be categorized into various types. Here is an overview of the main classifications.

Plain Aluminum Foil

Plain aluminum foil is the most common type, characterized by its flat surface and uniform thickness. It is primarily used in air conditioning evaporators and condensers as a thermal medium to enhance heat exchange efficiency. The manufacturing process of plain aluminum foil is straightforward, and its cost is relatively low, making it widely used in various types of air conditioning equipment.

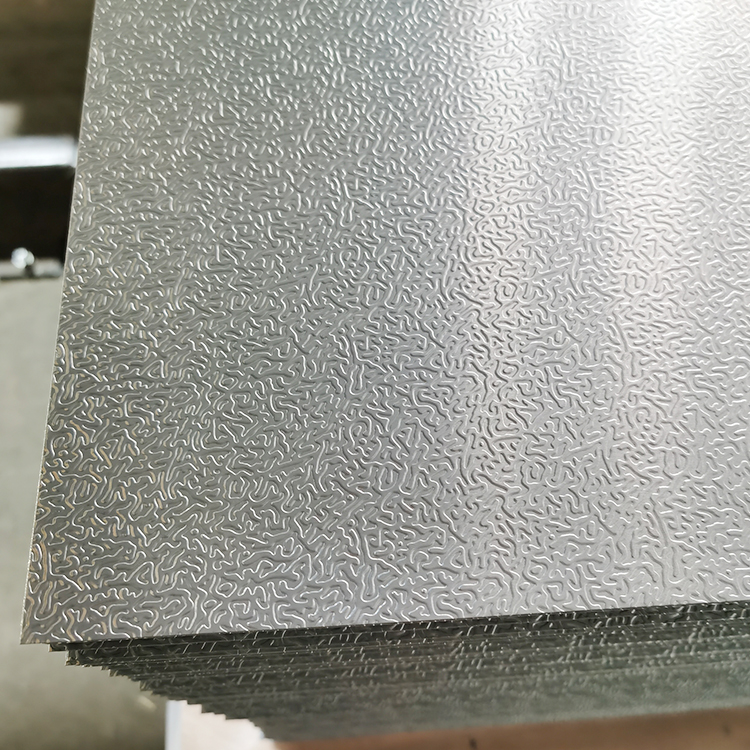

Folha de alumínio em relevo

Embossed aluminum foil features patterns or textures on its surface achieved through embossing. This treatment increases the surface area of the foil, enhancing its thermal conductivity and oxidation resistance. Embossed aluminum foil is mainly used in air conditioning condensers, significantly improving heat exchange efficiency while reducing frost formation.

Folha de alumínio revestida

Coated aluminum foil has a special coating applied to its surface to improve its corrosion resistance and oxidation resistance. Based on the coating materials, coated aluminum foil can be categorized into anti-corrosion coated foil, antibacterial coated foil, and hydrophilic coated foil, among others. It is widely used in air conditioning evaporators and condensers, especially in high-humidity and corrosive environments.

Hydrophilic Aluminum Foil

Hydrophilic aluminum foil undergoes a special treatment to give it good hydrophilicity, allowing it to quickly absorb and dissipate moisture. It is primarily used in air conditioning evaporators to prevent the formation of water droplets, reduce air resistance, and improve heat exchange efficiency. Additionally, hydrophilic aluminum foil has antibacterial and anti-mold properties, ensuring the hygiene and safety of air conditioning equipment.

Double-Sided Aluminum Foil

Double-sided aluminum foil is treated on both sides to impart similar or different characteristics. For example, one side may undergo hydrophilic treatment while the other side receives a coating treatment, providing both hydrophilicity and corrosion resistance. Double-sided aluminum foil is mainly used in high-performance air conditioning equipment, meeting various usage requirements and enhancing overall performance.

High-Strength Aluminum Foil

High-strength aluminum foil is manufactured through specific alloy compositions and heat treatment processes, giving it higher strength and durability. It is mainly used in air conditioning condensers and evaporators, capable of long-term use in high-pressure and high-temperature environments without deformation or cracking. It is suitable for large-scale air conditioning equipment and industrial air conditioning systems.

Conclusão

Air conditioning aluminum foil, based on different surface treatments and alloy compositions, can be classified into plain aluminum foil, embossed aluminum foil, coated aluminum foil, hydrophilic aluminum foil, double-sided aluminum foil, and high-strength aluminum foil. Each type of aluminum foil has unique properties and application areas, meeting the needs of different air conditioning equipment. With the continuous advancement of air conditioning technology, the types and performance of air conditioning aluminum foil will continue to improve, contributing significantly to the efficient operation and energy-saving aspects of air conditioning systems.