Battery aluminum foil is a critical component in the production of batteries, particularly in lithium-ion batteries, which are widely used in various applications such as electric vehicles, portable electronics, and renewable energy storage systems. The production of high-quality battery aluminum foil requires stringent technical requirements to ensure the performance, reliability, and safety of the batteries. Here are the key technical requirements for producing battery aluminum foil:

Purity of Aluminum

The aluminum used for battery foil must have a high degree of purity, typically above 99.99%. High-purity aluminum ensures low impurity levels, which is crucial for the electrochemical performance of the battery. Impurities can affect the foil’s conductivity and lead to unwanted chemical reactions, reducing the battery’s efficiency and lifespan.

Thickness and Uniformity

Battery aluminum foil must have a precise and uniform thickness. Common thickness ranges from 10 to 20 micrometers. Uniform thickness is essential for consistent coating and performance. Variations in thickness can lead to uneven coating of active materials, causing performance issues and potential safety hazards.

Propriedades mecânicas

The foil must exhibit excellent mechanical properties, including high tensile strength and elongation. These properties ensure the foil can withstand the mechanical stresses during battery assembly and operation without breaking or deforming. Good mechanical properties also contribute to the battery’s structural integrity.

Surface Quality

The surface of the aluminum foil must be smooth, clean, and free from defects such as scratches, pits, or contaminants. Surface defects can affect the adhesion of the active material coatings, leading to performance degradation. A clean and smooth surface ensures optimal contact and bonding with the battery’s electrodes.

Condutividade eléctrica

High electrical conductivity is crucial for battery aluminum foil as it directly affects the battery’s ability to conduct electric current efficiently. The foil should have a low electrical resistivity to minimize energy losses and improve the battery’s overall efficiency.

Resistência à corrosão

Battery aluminum foil must be resistant to corrosion, especially in the electrolyte environment within the battery. Corrosion can lead to foil degradation and failure of the battery. Proper alloying and surface treatments can enhance the foil’s corrosion resistance.

Coating Compatibility

The foil should be compatible with various coatings used in battery production, such as cathode or anode active materials. The adhesion between the foil and the coating must be strong and durable to ensure the long-term stability and performance of the battery.

Dimensional Tolerances

Strict dimensional tolerances must be maintained during the production of battery aluminum foil. This includes precise control of width, length, and thickness. Tight dimensional control ensures the foil fits properly within the battery cells and contributes to the overall efficiency of the manufacturing process.

Tratamento térmico

Proper heat treatment processes are essential to achieve the desired mechanical properties and surface characteristics of the aluminum foil. Heat treatment can help in stress relieving, enhancing ductility, and improving the overall quality of the foil.

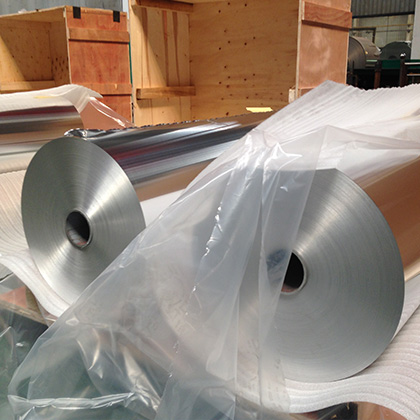

Packaging and Handling

Packaging and handling of the battery aluminum foil must be done carefully to prevent contamination and mechanical damage. The foil should be stored in a clean and controlled environment to maintain its quality until it is used in the battery production process.

Conclusão

Producing high-quality battery aluminum foil requires meticulous attention to several technical requirements. These include ensuring high purity, precise thickness, excellent mechanical properties, and optimal surface quality. Additionally, the foil must exhibit high electrical conductivity, corrosion resistance, and compatibility with various coatings. Meeting these technical requirements is essential to ensure the performance, reliability, and safety of batteries in various applications.