What Is a Heavy Duty Aluminum Foil Roll?

Heavy duty aluminum foil rolls are products in which aluminum foil is supplied or stored in larger reels. Typically, aluminum foil is sold in reels for easy transport, storage and use. Heavy-duty aluminum foil jumbo rolls have a large size and weight and are mainly used in industrial fields and large-scale applications. Due to their large size and weight, they are usually suitable for automated production lines or large machinery equipment, which can meet the order requirements of mass production and demand.

Difference Between Heavy Duty Aluminum Foil Rolls And Standard Aluminum Foil Rolls:

1 Thickness: Heavy-duty aluminum foil has a greater thickness than standard aluminum foil. Standard aluminum foil usually has a thinner thickness, generally between a few microns to tens of microns, while the thickness of heavy-duty aluminum foil is more than 30 microns (0.03 mm), or even thicker.

2 Strength and rigidity: Due to the difference in thickness, heavy duty aluminum foil usually has higher strength and rigidity. It can withstand greater stress and pressure, has better physical properties, and is suitable for some applications requiring higher strength and durability.

3 Insulation properties: Heavy-duty aluminum foil generally performs better in terms of insulation. Due to its greater thickness, heavy-duty aluminum foil has better insulation and can be used for protection from outside heat. In comparison, standard aluminum foil has weaker insulating properties.

4 Application fields: Due to its special properties, heavy-duty aluminum foil is often used in industrial fields, building materials, electronic products and other occasions that require higher strength and durability. Standard aluminum foil is widely used in food packaging, baking, barbecue foil and other fields.

Advantages of High Quality Heavy Duty Aluminum Foil Rolls:

Strength and durability: Heavy duty aluminum foil rolls of excellent quality are strong and durable, allowing them to bear more strain and pressure. This increases its dependability in applications and offers long-term security and consistency of performance.

Thermal performance: High grade heavy duty aluminum foil roll has good thermal insulation due to its great thickness. It efficiently prevents the influence of outside heat, maintains the temperature of the packaged objects at a constant level, and effectively isolates heat transfer.

Barrier performance: A high-quality, heavy-duty aluminum foil roll has good barrier performance, which can successfully prevent the passage of outside elements like oxygen, moisture, light, and odor. In applications like food packaging and chemical packaging, it can thus offer great protection, extending the shelf life and quality.

Processing properties: High-quality, heavy-duty aluminum foil rolls typically have good processing properties, allowing for processing operations such as folding, bending, cutting and forming. This makes it more flexible and versatile in a variety of applications, able to meet the needs of different shapes and sizes.

What Is Heavy Duty Aluminum Foil Used For?

- Industrial packaging: such as mechanical parts, electronic equipment, aerospace components, etc.

- Building materials: such as roof insulation materials, waterproof layers, insulation materials, etc.

- Food packaging: such as large food containers, food packaging bags, etc.

- Chemical packaging: such as packaging chemicals, pharmaceuticals, coatings, liquids and powders, etc.

How To Choose a Reliable Heavy Duty Aluminum Foil Roll Supplier?

- Quality:

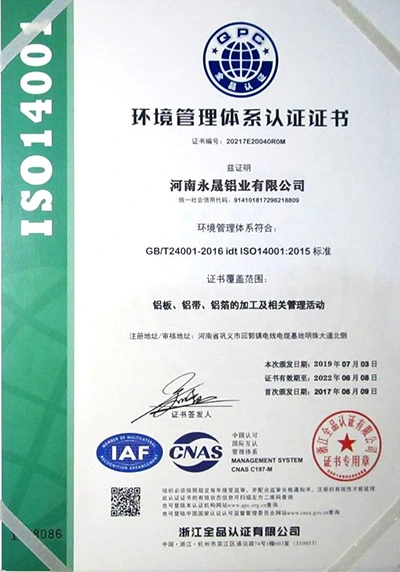

Verify the supplier’s quality control system and become familiar with its quality management practices. For example, find out if the supplier has ISO certification or any other necessary quality certifications. Inquire with the supplier about their stringent quality control procedures and standards.

Suppliers must deliver quality-related data and documents, including product certification, product specifications, and quality inspection results. These records provide a valuable foundation for assessing the supplier’s product quality.

Examine the supply chain management of suppliers; learn how they choose their raw materials, how they buy them, how they manage and keep an eye on their supply networks. This makes it easier to guarantee the consistency and dependability of product quality.

Find customer testimonials and testimonials from suppliers: Read customer testimonials and testimonials from suppliers to learn about their actual product quality performance and customer satisfaction.

- Cost:

Compare the prices offered by various suppliers: Compare prices from several providers to gain an understanding of market pricing. This aids in establishing a suitable price range and prevents being duped by excessively high or cheap costs.

Be mindful of unforeseen costs: Pay attention to any extra expenditures in addition to the product’s purchase price, such as shipping, packaging, duty and tax, and other expenses. When comparing and choosing providers, be sure to keep these things in mind.

- Deliver:

Understand the supplier’s production capacity and supply stability: ask the supplier’s production equipment, production capacity and supply capacity. Make sure suppliers are able to meet your needs on time and have adequate inventory management capabilities.

Lead times and flexibility: Discuss lead times with suppliers and find out if they have the ability to respond to rush orders or change requests. Supplier delivery punctuality and flexibility are critical to your production planning.

- Serve:

Technical support and after-sales service: Find out if the supplier provides technical support, answering questions and after-sales service. Do they have a professional technical team that can provide assistance and solutions when needed.

Communication and cooperation skills: It is very important to establish a good communication and cooperation relationship with suppliers. Understand their communication methods and feedback mechanisms to ensure timely communication and resolution of issues.

Flexible Order Management: Assess the supplier’s flexibility in order management and processing. Whether they can meet your customized needs, small batch orders or urgent orders, etc.

Yongsheng Aluminum Foil Key Product Introduction:

- Battery Aluminum Foil: Used as a current collector for lithium-ion batteries. Typically, the lithium-ion battery industry uses rolled aluminum foil as the positive electrode current collector. Rolled foils vary in thickness from 10 to 50 microns. Commonly used pure aluminum foils for lithium batteries include various alloy grades such as 1060, 1050, 1145, and 1235 aluminum foils, and have states such as O, H14, H24, H22, and H18.

- Air Conditioning Aluminum Foil (Hydrophilic Foil): Most commonly used in condensers and evaporators in air conditioning systems to conduct heat and isolate air flow. Generally speaking, the thickness of air-conditioning aluminum foil is usually between 0.08mm and 0.2mm, and the specific thickness depends on the design requirements and application scenarios of the air-conditioning system. Commonly used air-conditioning aluminum foil grades include 1100, 3003, Folha de alumínio 8011, etc., and the common states are H22, H24, etc.

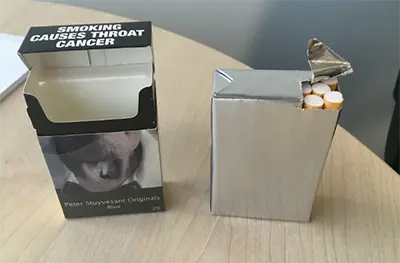

- Cigarette Packaging Aluminum Foil: mainly used in the cigarette packaging industry to protect cigarettes from moisture, oxygen and light while maintaining the freshness and quality of cigarettes. Generally speaking, the thickness of aluminum foil for cigarette packaging is usually between 0.006mm and 0.007mm to meet the packaging requirements and provide good barrier properties. Commonly used cigarette packaging foil grades include 1235, 8011 aluminum foil, etc., and the common states are O (soft state) and H18 (hard state).

- Aluminum Foil For Flexible Packaging: It is widely used in the packaging of food (such as 8079 folha de alumínio), pharmaceuticals and cosmetics industries to protect products from moisture, oxygen, light and odor, and to extend the shelf life of products. Generally speaking, the thickness of aluminum foil for flexible packaging is usually between 0.006mm and 0.020mm, and the specific thickness depends on the requirements of the packaging and the nature of the product. Commonly used flexible packaging aluminum foil grades include 1060, 1235, 8011, etc., and the common states are O (soft state) and H18 (hard state). 8011-O aluminum foil with a thickness of 0.009-0.08mm is generally used for household foil/tableware foil; 8021 aluminum foil is often used for pharmaceutical packaging.

- Decorative Aluminum Foil: It is often used in architectural decoration, furniture decoration and packaging decoration to increase the aesthetics and decorative effect of products. Generally speaking, the thickness of decorative aluminum foil is usually between 0.018mm and 0.5mm, and the specific thickness depends on the decoration requirements and application scenarios. Commonly used decorative aluminum foil grades include 1100, Folha de alumínio 3003, etc., and the common states are H14, H16, etc.

People Often Ask:

Can You Put Aluminum Foil In The Toaster Oven?

Yes, aluminum foil is oven safe. It is a heat-resistant material that can withstand high temperatures. Melting point is approximately 660 degrees Celsius (1220 degrees Fahrenheit) and the reflective surface helps distribute heat evenly. These properties make it suitable for a variety of oven applications such as wrapping, covering and lining. At that point be aware that foods with high acidity, such as tomatoes or citrus fruits, can react with the foil at high temperatures. This reaction may cause the foil to rupture and possibly transfer the aluminum to the food. To avoid this, it is recommended to use a layer of parchment between the acidic food and the foil.

Is Aluminum Foil A Conductor?

Yes, aluminum foil is conductive and can conduct electricity.