Mirror polished aluminum and glass mirrors are common reflective materials, and they are widely used in various fields. Mirror aluminum is an anodized and polished aluminum material that has a highly reflective surface. It provides a layer of protection through the oxide layer formed by the anodizing process, making the aluminum material highly resistant to wear and corrosion. Aluminum mirror is also polished to give it a smooth and flat surface that produces clear reflections.

In contrast, glass mirrors use glass materials whose surfaces are specially treated to achieve a reflective effect. Glass itself has excellent optical properties and can provide high light transmittance and refractive index. The surface of the glass mirror is treated with a coating or metal reflective layer to make it reflective. Below I will introduce to you the difference between aluminum mirror and glass mirrors:

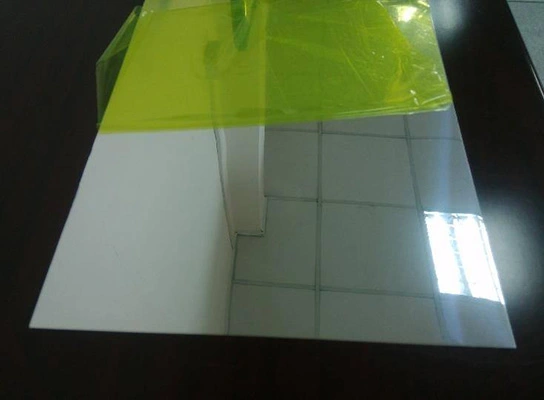

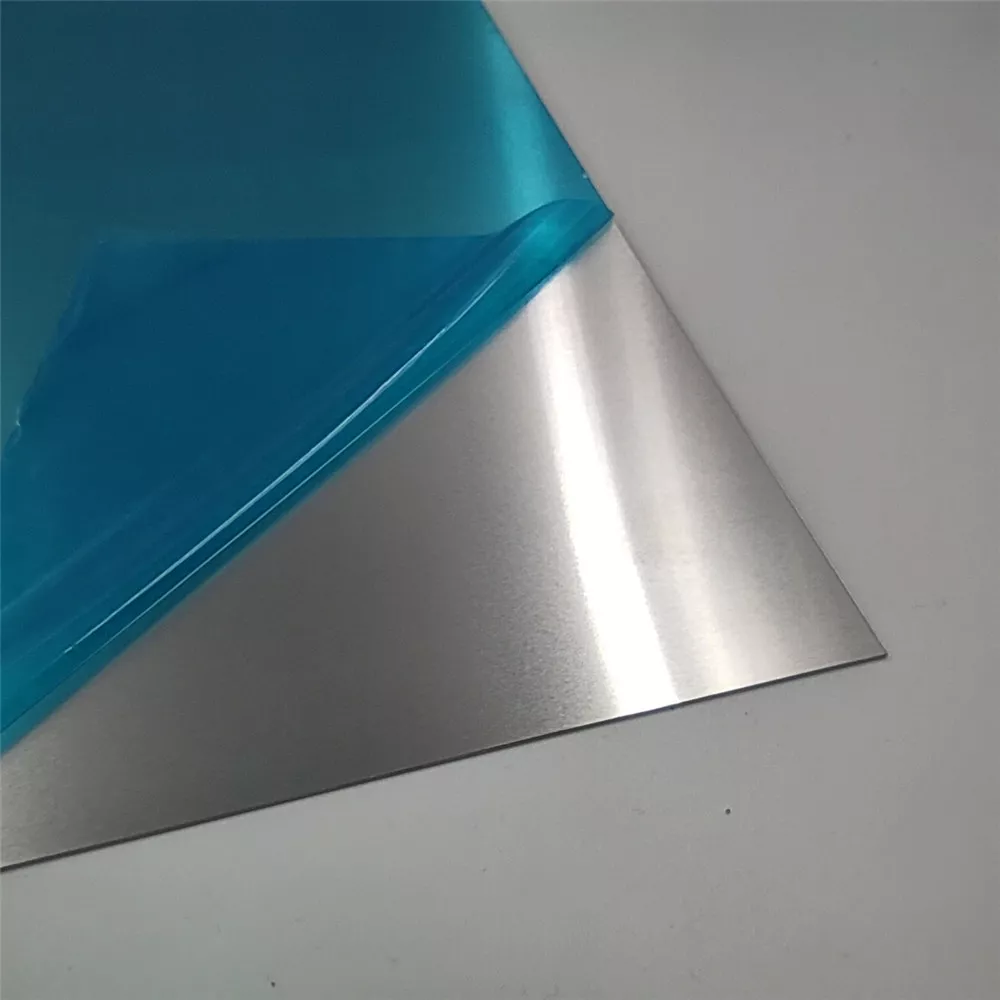

Mirror Polished Aluminum

Mirror polish aluminum refers to aluminum sheets that have undergone a polishing process to achieve a highly reflective and smooth surface. This material is known for its exceptional clarity and reflectivity. The manufacturing process involves several steps, including cleaning, sanding, buffing, and polishing.

Advantages of Mirror Polished Aluminum

Highly Reflective: The surface of aluminum mirror is anodized and polished, making it highly reflective, providing clear and accurate reflections.

Corrosion resistance: Polished mirror aluminum has high corrosion resistance and can maintain its reflective properties in harsh environments and extend its service life.

Smooth surface: Through polishing treatment, the surface of aluminum mirror becomes smooth and flat, reducing surface defects and unevenness, and improving its reflective effect.

Lightweight: Compared to other materials such as glass, mirrored aluminum has a lower density, making it relatively lightweight and easy to handle, install and transport.

Processability: Mirror finish aluminum has high processability and can be processed by cutting, bending, stamping and welding to meet the needs of different applications.

Wear Resistance: Anodizing makes mirror polishing aluminum more wear-resistant, able to resist scratches and scuffs from daily use.

How To Polish Aluminum To A Mirror Finish?

Material preparation:

Aluminum substrate: Choose high-purity aluminum alloy as the substrate, usually industrial grade or optical grade aluminum.

Polishing tools: Prepare the tools required for polishing, such as polishing machine, polishing disc, sanding paper and polishing fluid.

Surface cleaning:

Before polishing, make sure the surface of the aluminum substrate is clean and dust-free. Use detergent and a dust-free cloth or cotton ball to gently wipe the aluminum surface to remove any dirt or grease.

Coarse grinding:

Use coarser sanding paper (such as #400 to #600 grade) or abrasive disc to sand the aluminum surface. Sanding can be done by hand or with the help of a polishing machine to ensure an even surface. During the sanding process, force should be applied evenly to avoid excessive wear or unevenness.

Medium grinding treatment:

Use finer sandpaper (such as #800 to #1200 grade) or abrasive disc to medium-grind the aluminum surface. Again, this can be done by hand or with the help of a polishing machine. The purpose of medium grinding is to further smooth the surface and remove the grinding marks left by rough grinding.

Fine grinding:

Use finer sandpaper (such as #1500 to #2000 grade) or abrasive discs to finely grind the aluminum surface. Ensure that the grinding marks are finer and more even, and the surface is smoother.

Polishing:

After completing the sanding step, start the polishing process. Use a polishing machine and polishing disc, apply appropriate polishing fluid (such as polishing wax or aluminum oxide abrasive powder), and rotate the aluminum surface to polish.

During the process, the rotation speed of the polishing machine, the amount of polishing fluid used, and the polishing time should be controlled. Using appropriate pressure and gentle techniques, polish the entire aluminum surface evenly until the desired mirror finish is achieved.

Clean and protect:

After polishing is complete, clean the aluminum alloy surface thoroughly using warm water and a mild detergent to remove polishing fluid and residue.

To protect polished alloy aluminum surfaces and prevent oxidation and damage, a protective coating can be applied. Commonly used protective coatings include silicone wax, liquid wax or varnish. Make sure the surface is dry and clean before applying the coating.

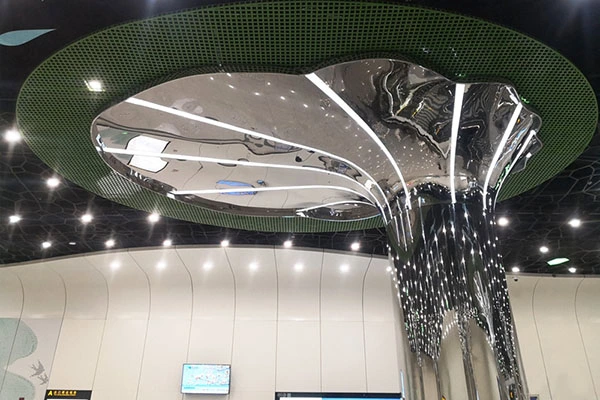

Applications of Mirror Polished Aluminum

We recommend that you use 1060 mirror aluminum, 1070 mirror aluminum and other 1000 series aluminum alloys for building decoration. Polished aluminum mirror has many specific application cases in the field of architectural decoration:

- Curtain walls and facade decoration: Aluminum mirror is widely used in curtain wall systems and facade decoration such as: facade panels, cladding, facade decoration, roof systems, etc.

- Interior wall decoration: Mirror polish aluminum is also often used for interior wall decoration, such as large commercial centers, office buildings, hotel lobbies, etc.

- Ceilings and suspended ceilings: Commonly found in commercial centers, exhibition halls, hotels and other places.

- Column and column decoration: Mirror finish aluminum can be used to decorate columns and columns in buildings, adding luster and modernity. This application is common in public buildings, large shopping malls, conference centers, etc.

- Indoor furniture and decorations: Polished aluminum mirror can be used in the production of indoor furniture and decorations, such as mirror frames, dining tables, cabinet doors, etc.

- Floor decoration: Aluminum mirror finish can also be used for floor decoration, such as floors, stair treads, etc.

Glass Mirrors

Glass mirror is an optical element made of a glass substrate coated with a metal film. It has a flat glass substrate and a metal reflective layer coated on it. Its main function is to reflect light, change its direction and focus or form an optical image.

Advantages of Glass Mirrors

High reflectivity: The metal reflective layer of the glass mirror can effectively reflect light and has high reflectivity. This enables glass mirrors to provide good reflective properties in optical systems for applications such as reflection, focusing and forming optical images.

Flatness and finish: The base material of a glass mirror is usually precisely processed and polished to have a high degree of flatness and finish. This enables the glass mirror to accurately reflect light, reduce scattering losses, and ensure the performance of the optical system.

Durability: The metal reflective layer of glass mirrors usually has good durability and can provide reflective function stably for a long time. In addition, the presence of a protective coating can effectively protect the reflective layer from damage such as scratches and corrosion.

Adjustability: By selecting different metal reflective layer materials and thicknesses, the reflective properties of the glass mirror can be adjusted. This enables glass mirrors to be used in optical systems with different wavelength ranges and to meet the requirements of specific applications.

Applications of Glass Mirrors

Glass mirrors are most commonly used for decoration. You can see them in commercial factories, furniture, automobile transportation, medical equipment, optical instruments, architectural design, and electronic equipment. It is not as medium-strength and good in tensile strength as mirror aluminum. The glass material is extremely easy to break and is not suitable for use in high-strength scenes. As a part of the aluminum alloy series, mirror aluminum can undergo stable anodizing, chemical polishing, atomization, sandblasting, color coating, etc., making it more resistant to corrosion and oxidation. Although glass mirrors are cheaper than mirror aluminum, mirror aluminum alloys are still irreplaceable in the fields of electronic product casings, reflective parts, furniture, home appliances, etc.!

Mirror Polished Aluminum Vs Glass Mirrors

- Reflectivity and clarity: Mirror-polished aluminum excels in reflectivity and clarity, providing precise and distortion-free reflections. Glass mirrors also have excellent reflectivity, but they may suffer from slight distortion due to the nature of the material.

- Durability and maintenance: Mirror polished aluminum is extremely durable and corrosion-resistant, making it suitable for outdoor applications. Glass mirrors are also durable but may require more maintenance to keep them clean and free of smudges and streaks.

- Weight and ease of installation: Polished aluminum is much lighter than glass mirrors, making it easier to handle and install, especially on larger projects. Glass mirrors are heavier and may require additional support during installation.

- Cost and affordability: Glass mirrors are generally less expensive than mirror aluminum. They are readily available and provide cost-effective solutions for a variety of applications. Mirror polish aluminum, while offering excellent reflectivity, tends to be more expensive.

- Aesthetic and design Possibilities: Both mirror polished aluminum mirrors and glass mirrors offer unique aesthetic qualities. Mirror polish aluminum adds a sleek and modern touch, while the glass mirror provides timeless elegance. The choice depends on the desired style and design goals.