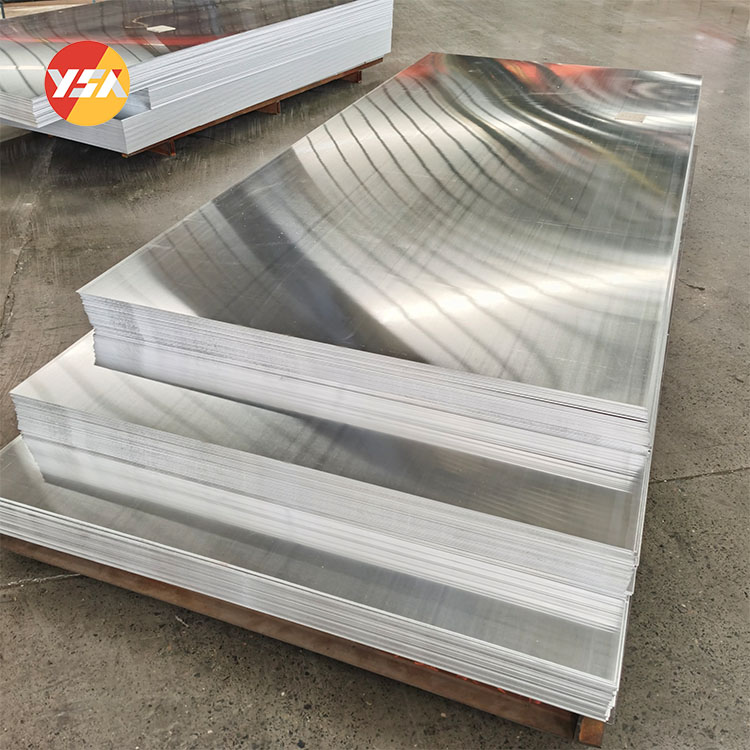

In modern industry, the metal stamping sector plays a vital role, especially in manufacturing, automotive, and electronics. One widely used material in this industry is the 4×8 aluminum sheet, which is favored for its unique properties and exceptional performance. This article explores the various applications of 4×8 aluminum sheets in the metal stamping industry and highlights their advantages.

Lightweight Material

Aluminum is renowned for its lightweight nature, striking an excellent balance between strength and weight compared to materials like steel. This characteristic significantly reduces the overall weight of finished products, making them more efficient for transportation and installation. For instance, in automotive manufacturing, using aluminum sheets can lower the weight of vehicles, enhancing fuel efficiency and handling performance. Additionally, the reduced weight contributes to increased operational flexibility, allowing components to be easily maneuvered and adapted in various applications, particularly in environments requiring frequent relocation.

Excellent Forming Capabilities

The forming capabilities of aluminum sheets are remarkable. They possess excellent ductility and malleability, allowing them to be shaped into complex forms through stamping processes. This enables designers to create innovative products that meet specific customer needs. For example, intricate parts for electronic devices, mechanical supports, and various assembly components can be efficiently produced. This capability is particularly important in automated equipment and machinery, where diverse functionalities and shapes are required to support different applications, resulting in higher production efficiency.

Corrosion Resistance of 4×8 Aluminum Sheet

One of the advantages of aluminum sheets is their natural corrosion resistance due to the formation of an oxide layer. This property allows 4×8 aluminum sheets to maintain their performance in harsh environments, extending the lifespan of products. For example, in the chemical industry and medical devices, aluminum sheets can effectively prevent the corrosion of liquids and gases, protecting the internal structures. Additionally, aluminum sheets used in outdoor applications (such as traffic signs and lighting fixtures) exhibit excellent weather resistance, safeguarding them against sunlight, rain, and other environmental factors.

Condutividade eléctrica

In applications requiring electrical connections and conductivity, aluminum sheets demonstrate good conductive properties. This makes them widely used for metal stamping components in electronic devices, enhancing reliability and performance. For instance, in the design of electrical appliance housings, aluminum sheets can serve as effective grounding materials, ensuring the safety of device operation. Furthermore, good electrical conductivity allows aluminum sheets to be utilized in cable racks and distribution boxes in power equipment, ensuring efficient performance.

Aesthetic Appeal and Versatility

In addition to functionality, the aesthetic aspect of modern industrial products is crucial. Aluminum sheets can undergo surface treatments such as anodizing and coating, allowing for a variety of visual options that enhance product appeal. This is especially relevant in the household appliance and consumer electronics sectors, where design elements like TV bezels and washing machine casings benefit from these treatments. The customization possibilities provided by aluminum sheets also enable companies to quickly adapt product designs to market demands, enhancing their competitive edge.

Broad Industry Applications

The adaptability of 4×8 aluminum sheets allows for extensive use across various industries. Whether in automation equipment, mechanical housings, household appliances, or automotive components, the use of aluminum sheets enhances overall product performance and meets diverse industry requirements. For example, in the aerospace sector, aluminum sheets are used for aircraft frames and interiors due to their lightweight and high-strength characteristics, improving aircraft performance. In construction, aluminum facades and decorative elements are often chosen for their combination of beauty and durability.

Future Trends

As technology advances, the application prospects for 4×8 aluminum sheets are becoming broader. Many companies are exploring intelligent manufacturing and automation solutions, fostering advancements in the precision and efficiency of aluminum stamping processes. Additionally, as environmental awareness increases, there is a growing emphasis on sustainable material choices, which may promote the recycling and green production of aluminum. The rising demand for lightweight and high-performance solutions will likely lead to the development of innovative aluminum alloys and products.

Conclusão

In summary, 4×8 aluminum sheets hold an irreplaceable position in the metal stamping industry due to their lightweight nature, excellent forming capabilities, corrosion resistance, good electrical conductivity, aesthetic appeal, and broad applicability. Whether in product design or functional implementation, aluminum sheets demonstrate unique advantages that create new opportunities for growth in the metal stamping sector. As industries continue to recognize the value of aluminum and technology evolves, the future application possibilities for aluminum sheets will expand, driving industrial innovation forward.