Aluminum strip is a crucial component in armored cables, providing additional mechanical protection and improving the electrical performance of the cables. The processing of aluminum strip during the production of armored cables is a critical stage involving multiple steps, each with specific technical requirements and quality standards. Below is a detailed overview of the processing of aluminum strip in armored cable production.

Material Preparation

The production of aluminum strip begins with the selection of high-quality aluminum alloy materials. Aluminum alloys are ideal for armored cables due to their lightweight, high strength, and excellent corrosion resistance. At this stage, the raw materials are first cut and cleaned to remove any surface oxide layers, oils, and impurities, ensuring good adhesion and conductivity in subsequent processing.

Aluminum Strip Forming

The next step is the forming of the aluminum strip, which is typically accomplished through rolling or extrusion processes. By controlling pressure and temperature, the aluminum alloy is processed into the desired thickness and width. This forming process requires precise dimensional control to ensure uniformity, which is crucial for the success of later processes. This is often done in efficient production lines to maximize both production efficiency and quality.

Tratamento de superfície

Once the aluminum strip is formed, it undergoes various surface treatments to enhance its corrosion resistance and adhesion properties. Common methods include anodizing and applying protective coatings. Anodizing forms a dense oxide layer on the surface of the aluminum strip, significantly improving its corrosion resistance and also enhancing its aesthetic appeal. These surface treatments extend the lifespan of the aluminum strip in harsh environments, ensuring long-term stability in cable performance.

Wrapping Process

During the assembly of armored cables, the aluminum strip is wrapped around the outside of the cable’s insulation layer. This can be done through winding or pressing, ensuring that the aluminum strip uniformly covers the outer layer of the cable to form an effective protective layer. It is essential to monitor the tension and overlap of the aluminum strip during this wrapping process to prevent air or moisture penetration that could affect cable performance.

Welding and Connection in Armored Cable

To ensure a tight and secure connection between segments of aluminum strip, welding or mechanical connections are employed. The welding process requires stringent control of temperature and welding time to guarantee the reliability of the connection and good electrical contact. This step is critical for the overall safety of the cable, minimizing the risk of overload or short circuits due to poor connections.

Quality Inspection

Quality inspection is an essential part of every stage of production. Advanced testing equipment is used to assess the thickness, strength, conductivity, and corrosion resistance of the aluminum strip. These inspections ensure that each roll of aluminum strip meets international and domestic standards and satisfies specific customer requirements.

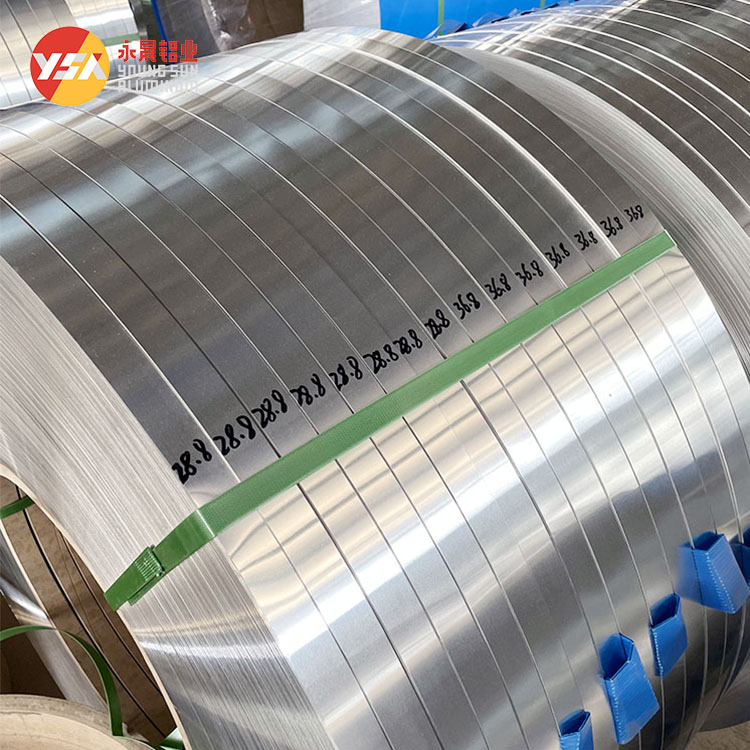

Packaging and Shipping

All aluminum strips that pass inspection are carefully packaged to protect them during transportation. Proper packaging not only helps reduce the risk of damage but also facilitates easier management during transport and storage.

Conclusão

The processing of aluminum strip in armored cable production is a closely connected and interdependent system engineering effort. Every detail directly impacts the overall quality and performance of the armored cables. By selecting high-quality aluminum materials, implementing precise processing techniques, and enforcing strict quality controls, manufacturers can significantly enhance the durability and safety of the cables, ensuring reliable operation in various environments. This commitment not only assures product quality but also guarantees the safe usage of the final product for end users.