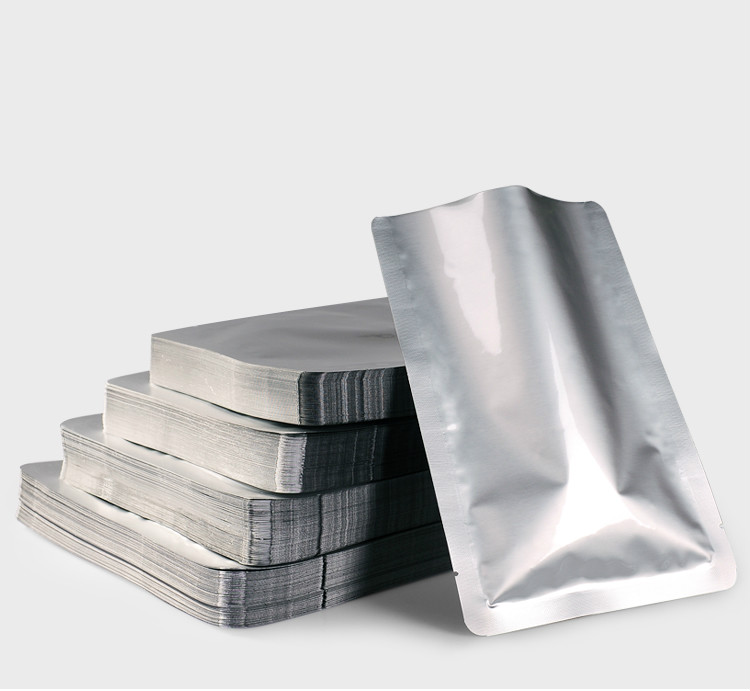

Алюминиевая фольга barriers film is widely used in packaging to protect food, pharmaceuticals, and electronic products. Due to its excellent barrier properties and lightweight characteristics, it has become a preferred material in many industries. However, many people may wonder: is aluminum foil barrier film actually made of pure aluminum foil? This article will thoroughly explore the composition, properties, applications, and environmental potential of aluminum foil barrier film, helping readers gain a comprehensive understanding of this important material.

Definition of Aluminum Foil Barrier Film

Aluminum foil barrier film is a thin film primarily made from aluminum foil that is combined with other materials through various processes such as lamination or coating. Its design aims to provide high barrier performance, effectively preventing moisture, oxygen, and light from permeating. Because of these superior barrier characteristics, aluminum foil barrier film is widely applied across different fields.

Composition of Aluminum Foil Barrier Film

Although the name includes “aluminum foil,” aluminum foil barrier film is not necessarily made up of pure aluminum foil. Typically, the structure of aluminum foil barrier consists of several key components:

– Aluminum Foil Layer: Serving as the main barrier layer, aluminum foil offers excellent protection against moisture, gases, and light, ensuring the longevity and freshness of the packaged contents. The thickness of the aluminum foil usually ranges from 0.01 mm to 0.2 mm.

– Substrate Layer: Aluminum foil is typically bonded with a plastic film (such as polyethylene or polyester) to form a composite material. This substrate layer not only enhances the mechanical strength of the film but also increases its durability and tear resistance, making it more reliable in practical applications.

– Adhesive Layer: During the lamination process, an adhesive is used to securely bond the aluminum foil layer to the substrate layer. The choice of adhesive is crucial, as it needs to meet food safety standards to avoid potential contamination of the packaged products.

This composite structure allows aluminum foil barrier to not only possess excellent barrier properties but also withstand various challenges encountered during everyday use, thus performing well in a variety of packaging applications.

Advantages of Aluminum Foil Barrier Film

Aluminum foil barrier bags boasts several significant advantages that make it a key player in the packaging industry:

– Exceptional Barrier Performance: Aluminum foil provides strong isolation capabilities, preventing moisture, oxygen, and light from penetrating. This is critical for maintaining the freshness and integrity of food and pharmaceuticals over time.

– Lightweight: Compared to traditional glass or metal packaging, aluminum foil barrier film is much lighter, making it easier to transport and store. Its lightweight nature not only reduces logistics costs but also enhances convenience for consumers during daily use.

– Recyclability: Aluminum can be recycled up to 95%, making aluminum foil barrier film an environmentally friendly choice. Proper recycling processes can effectively utilize resources, aligning with the sustainability goals of modern society.

Приложения

Aluminum foil barrier bag has a wide range of applications, primarily including:

– Food Packaging: It is commonly used in snack packaging, beverage containers, and frozen food wraps. This film effectively preserves the taste and freshness of food while preventing external contamination.

– Pharmaceutical Packaging: Aluminum foil barrier film is widely utilized for the safe packaging of pharmaceuticals, effectively preventing moisture and oxygen from affecting the active ingredients, thus ensuring long-lasting efficacy.

– Electronics: In the electronics sector, aluminum foil barrier film is used to protect sensitive components from electromagnetic interference and is commonly found in battery packaging to maintain performance and safety.

– Consumer Goods Packaging: Many everyday products, such as cosmetics and cleaning agents, also employ aluminum foil barrier film to ensure product quality and stability.

Экологические соображения

With the rise of environmental awareness, the potential of aluminum foil barrier film in sustainability has garnered increasing attention. Key considerations include:

– Circular Economy: The high recyclability of aluminum allows for more efficient integration into the circular economy. The energy required to recycle aluminum is only about 5% of that needed for producing new aluminum, significantly reducing waste of resources.

– Research on Alternative Materials: To further improve the environmental performance of aluminum foil barrier film, many research institutions are exploring new substrate materials, such as bio-based plastics and biodegradable materials, to reduce dependence on petroleum-based resources.

– Reducing Plastic Usage: In certain applications, aluminum foil barrier film can help minimize the usage of plastic materials, contributing positively to environmental sustainability.

Future Development Trends

As technology continues to advance, design and manufacturing processes for aluminum foil barrier film are also evolving. For instance, the rise of smart packaging technology allows the integration of sensors into aluminum foil barrier films to monitor product conditions and freshness. This will further enhance the functionality of aluminum foil barrier films, meeting the growing demands of the market.

Заключение

Aluminum foil barrier film is not always made of pure aluminum foil but is instead a composite product made from aluminum foil and substrate layers. This design not only enhances barrier performance but also provides good mechanical strength and flexibility for various applications. With the increasing focus on environmental sustainability, aluminum foil barrier film holds significant potential for providing sustainable packaging solutions in the future.