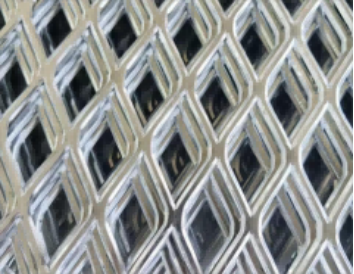

Aluminum mesh is an important material used across various industries, including construction, transportation, and decoration, valued for its lightweight, high strength, and corrosion resistance. The production process involves multiple steps, each critical to the quality and performance of the final product. This article will provide an in-depth look at the production process of aluminum mesh, helping you understand how this versatile material is made.

Raw Material Selection

The production of aluminum mesh begins with selecting high-quality aluminum alloy materials. Commonly used alloys include 6061 and 5052, known for their excellent mechanical properties and good corrosion resistance. Choosing the right aluminum material is essential to ensure the strength and durability of the mesh, as well as its adaptability in specific environments. During this stage, quality control measures are implemented to verify the chemical composition, thickness, and condition of the raw materials to meet production standards.

Cutting and Forming of Aluminum Mesh

Once the raw materials are confirmed to be suitable, the production process moves on to the cutting and forming phase. The aluminum alloy materials are cut into the required sizes and shapes based on design specifications. This step often utilizes advanced techniques such as laser cutting, CNC cutting, or mechanical cutting to ensure precision and smooth edges. Following this, processes like punching, stretching, extrusion, or mesh forming are employed to create the mesh structure. Precise control of forming parameters, including temperature, pressure, and time, is crucial to meet the desired dimensions, shapes, and thicknesses.

Welding and Connecting

The welding process is a key step that directly impacts the strength of connections between mesh pieces and the overall stability of the aluminum mesh. Common welding methods include TIG welding, laser welding, and spot welding. The appropriate welding technique is selected based on the material’s characteristics and thickness to ensure the quality and uniformity of the welds. After welding, joints are cleaned and treated to enhance strength and minimize the impact on material performance.

Обработка поверхности

Surface treatment not only enhances the appearance of aluminum mesh but also significantly boosts its resistance to corrosion and wear. Common surface treatment methods include anodizing, powder coating, and electrophoretic coating. Anodizing creates a protective layer on the aluminum surface through an electrochemical reaction, increasing weather resistance and abrasion resistance, while powder coating allows for various colors and patterns to meet customer preferences. This step, often referred to as “protective treatment,” is vital for adding value to the final product.

Quality Inspection

After production, quality inspection is paramount. To ensure that every aspect of the aluminum mesh meets industry standards and customer requirements, manufacturers usually implement stringent testing procedures. These include measurements for size, strength testing, and examination of surface quality. Specialized testing equipment such as ultrasonic testing and X-ray inspection ensures that all products meet safety and durability specifications. Any defects or non-conforming products identified during this phase require rework or rectification to guarantee that only compliant products are shipped.

Packaging and Shipping

The final step involves packaging and shipping the qualified aluminum mesh. To prevent damage during transportation, aluminum mesh is typically packaged with moisture-resistant and impact-absorbing materials, ensuring that products arrive intact. Thoughtful packaging design reduces friction and impacts during transit, lowering the rate of damages. Additionally, companies must choose reliable logistics providers to ensure the safety and timeliness of deliveries, meeting customer deadlines effectively.

Заключение

The production process of aluminum mesh is a complex and meticulous process involving several key stages. From raw material selection to final packaging and shipping, each step plays an essential role in ensuring a high-quality aluminum mesh product that meets market demands. With advancements in technology and continuous improvements in production processes, the performance and application range of aluminum mesh are likely to expand further, offering superior products across various industries.