Введение

Aluminum sheet is a versatile and widely used metal in various industries due to its lightweight, durability, and corrosion resistance. Aluminum sheets are a popular form of aluminum used in applications ranging from construction to automotive manufacturing. When working with aluminum sheets, it is essential to understand how to calculate their weight and determine their price accurately. In this blog, we will delve into the methods for calculating the weight and price of aluminum sheets, providing you with valuable insights.

Understanding Aluminum Sheet Weight Calculation

Aluminum sheet weight calculation is crucial for determining the amount of material required for a project and estimating transportation costs. The weight of an aluminum sheet can be calculated using the following formula:

Weight (kg) = Length (m) x Width (m) x Thickness (mm) x Density (g/cm³)

Density is an essential parameter that varies depending on the type of aluminum alloy used. For instance, the density of pure aluminum is approximately 2.7 g/cm³. However, different alloys have different densities, so it is necessary to refer to material specifications or consult with suppliers to obtain the accurate density value.

Converting Weight Units

Sometimes, you may come across weight measurements in units other than kilograms. To convert weight units, you can use the following conversion factors:

1 kilogram (kg) = 1000 grams (g)

1 kilogram (kg) = 2.20462 pounds (lbs)

Converting between these units will help you communicate weight measurements effectively and work with different weight standards as required.

Calculating Aluminum Sheet Price

Calculating the price of an aluminum sheet involves considering various factors such as the alloy type, sheet thickness, dimensions, and market pricing. Here’s a general formula to estimate the price of an aluminum sheet:

Price = (Base Price per Unit Area + Alloy Surcharge) x Sheet Area

Let’s break down each component:

- Base Price per Unit Area: This is the base cost of aluminum per unit area, which can vary depending on the alloy type and market conditions. It is typically provided by aluminum suppliers or can be obtained from metal pricing indexes. The unit of measurement is usually in currency per square unit (e.g., USD per square meter).

- Alloy Surcharge: Some aluminum alloys may incur an additional surcharge due to their specific composition or market factors. The alloy surcharge is an extra cost added to the base price per unit area and can be expressed as a percentage or a fixed value.

- Sheet Area: The sheet area is calculated by multiplying the length and width of the sheet. Make sure to use consistent units (e.g., meters or feet) for accurate calculations.

By multiplying the base price per unit area by the sheet area and adding the alloy surcharge, you can estimate the total price of the aluminum sheet.

It’s important to note that the prices can vary significantly based on market fluctuations and specific supplier pricing policies. Additionally, for large or bulk orders, there may be quantity discounts or negotiated prices available. To obtain precise pricing information, it is recommended to contact aluminum suppliers or distributors who can provide accurate quotes based on your specific requirements.

Price Differences of Different Aluminum Alloy Aluminum Plates

The prices of different aluminum alloy plates can be different based on several factors, including the specific alloy composition, thickness, size, market demand, and supplier pricing policies. Here’s a common overview of the price differences among common aluminum alloy plates:

- 1000 Series Aluminum Plates: The 1000 series aluminum plates, such as 1050, 1060, and 1100, are commonly the least expensive owing to their high purity and low alloying elements. These plates are generally used in general-purpose uses and have relatively lower strength compared to other alloy series. The prices for 1000 series aluminum plates are typically lower compared to alloys with additional alloying elements.

- 3000 Series Aluminum Plates: The 3000 series aluminum plates, such as 3003 and 3004, are alloyed with manganese for improved strength and corrosion resistance. These plates offer good formability and weldability and are often used in general-purpose uses where moderate strength is needed. The prices for 3000 series aluminum plates are generally slightly higher than those of the 1000 series owing to the alloying element addition.

- 5000 Series Aluminum Plates: The 5000 series aluminum plates, such as 5052 and 5083, are alloyed with magnesium for increased strength and fantastic corrosion resistance, particularly in marine environments. These plates offer good formability and weldability and are generally used in marine, automotive, and structural uses. The prices for 5000 series aluminum plates are typically higher than those of the 3000 series due to the added strength and corrosion resistance properties.

- 6000 Series Aluminum Plates: The 6000 series aluminum plates, such as 6061 and 6063, are alloyed with magnesium and silicon for good formability, weldability, and moderate to high strength. These plates offer excellent corrosion resistance and are widely used in many kinds of structural and architectural applications. The prices for 6000 series aluminum plates can be different depending on the specific alloy and temper, with higher-strength variants generally being more expensive.

- 7000 Series Aluminum Plates: The 7000 series aluminum plates, such as 7075, are alloyed with zinc for increased strength and hardness. These plates offer very high strength and good machinability, making them suitable for aerospace, high-stress applications, and structural components. The prices for 7000 series aluminum plates are typically higher compared to other series due to their high strength and specialized applications.

Factors Influencing Price Differences

- Alloy Composition and Purity: The composition and purity of the aluminum alloy significantly impact the price of aluminum plates. Aluminum alloys with higher purity levels, such as 99.99% pure aluminum, are generally more expensive due to the advanced refining processes required to achieve such high levels of purity. These high-purity alloys are often used in applications where exceptional corrosion resistance or electrical conductivity is required.

- Производственные процессы: The manufacturing processes involved in producing aluminum plates can also affect their prices. Different alloys may require specific processing techniques, such as casting, rolling, or extrusion, which can influence the overall cost. More complex manufacturing processes or those involving additional steps may result in higher prices.

- Alloy Series and Grades: Aluminum alloys are classified into different series, such as the 1000, 3000, 5000, 6000, and 7000 series. Each series has its own unique properties and applications. Generally, alloys in the 2000, 6000, and 7000 series, which contain additional alloying elements such as copper, magnesium, or zinc, tend to be more expensive than alloys in the 1000 series или 3000 series. The presence of these alloying elements enhances specific properties of the aluminum, such as strength, corrosion resistance, or heat treatability, thus contributing to the higher price.

- Условия рынка: Market conditions, including supply and demand dynamics, global economic factors, and trade policies, can also influence the price differences among aluminum alloys. Fluctuations in the availability of raw materials, changes in production capacities, and geopolitical factors can impact the overall cost of aluminum plates.

- Sheet Size and Thickness: The dimensions and thickness of aluminum plates can affect their prices. Larger plates or plates with non-standard thicknesses may require additional processing steps, resulting in increased production costs. Additionally, the weight of the plate influences transportation costs, which can also impact the final price.

- Quantity and Supplier: The quantity of aluminum plates ordered and the choice of supplier can lead to price variations. Bulk orders often attract discounts, as suppliers may offer volume-based pricing structures. It is also important to consider the reputation and quality of the supplier, as these factors can influence the pricing.

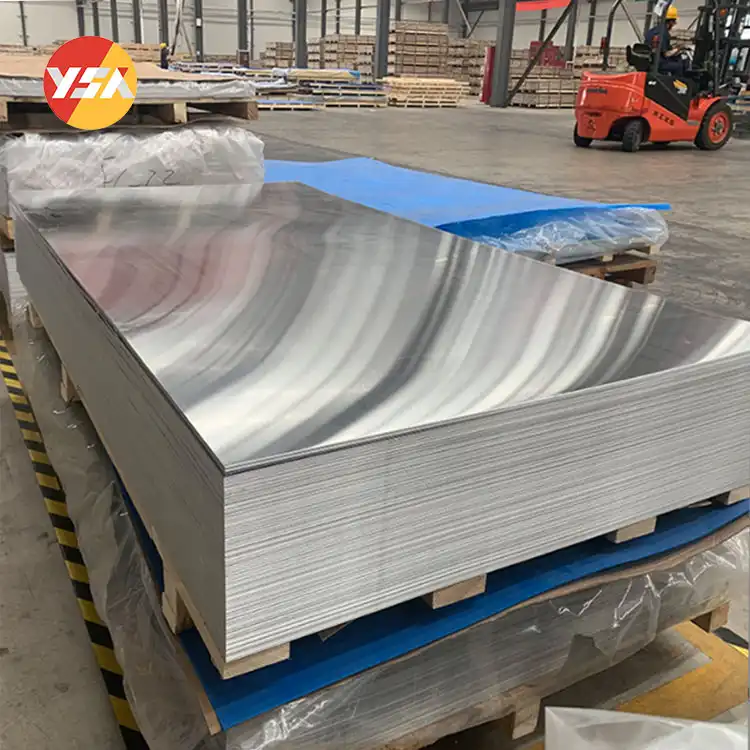

Yongsheng Aluminum Sheet Introduction

Henan Yongsheng Aluminum Co., Ltd., as a leading supplier of aluminum panels, they take pride in offering high-quality products at competitive prices. The aluminum panels are crafted using premium-grade materials and adhere to stringent manufacturing standards to ensure exceptional durability, corrosion resistance, and longevity. They provide a wide range of customization options, including various sizes, thicknesses, finishes, and colors, allowing them to meet the unique requirements of every project. Yongsheng Aluminum has its own independent factory. Yongsheng has many customers around the globe. And the products have high repurchase rate. The factory is located in Gongyi Aluminum Industrial Park, Henan Province, which is the largest aluminum industry cluster in China. Welcome to visit the factory and establish a long-term business relationship.

Резюме

Calculating the weight and price of aluminum sheets is essential for accurate material estimation and budgeting in various industries. By understanding the formula for weight calculation and considering key factors when determining the price, you can make informed decisions and optimize your aluminum sheet purchasing process. Remember to consult with suppliers, stay updated on market trends, and consider the specific requirements of your project to obtain the most accurate weight and price calculations.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

What is the weight of a 3 mm aluminum sheet?

Generally, a 3mm aluminum sheet weighs 8.1 pounds per square meter.

How much does a 2 mm sheet weigh?

Generally, a 2mm aluminum sheet weighs 5.4 kilos per square meter.

How is density determined?

Divide the mass of the substance by the volume of the material to determine its density.