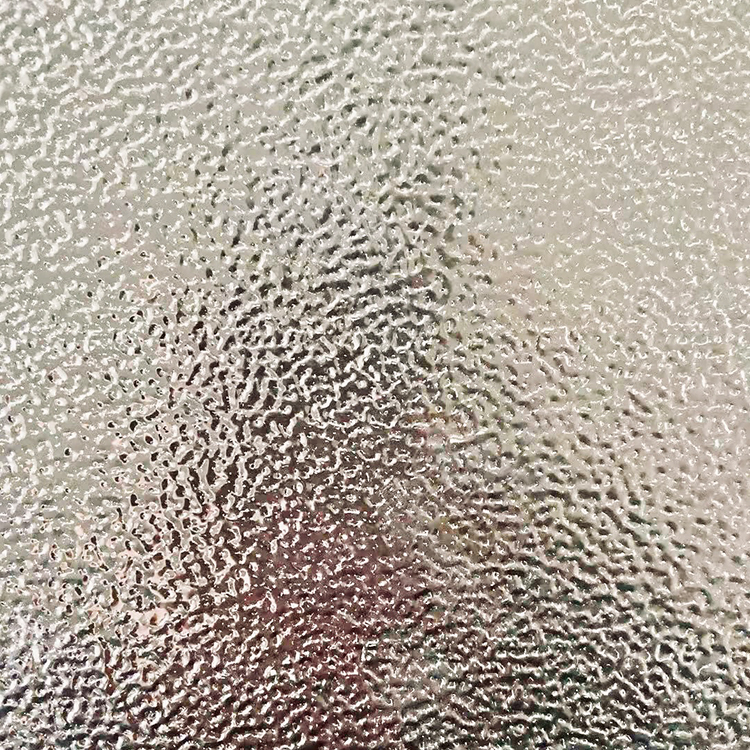

Embossed aluminum sheets are widely used in construction, automotive, and home appliance industries due to their lightweight, high strength, corrosion resistance, and aesthetic appeal. However, during the processing of embossed aluminum sheets, various issues can arise, affecting product quality and production efficiency. This article explores the common problems encountered in processing embossed aluminum sheets and their solutions.

1. Surface Scratches

Causes:

Material collides with hard objects during handling or storage.

Processing equipment or tools are not clean.

Impurities or damage on the surface of the embossing roller or mold.

Solutions:

Use appropriate protective measures, such as packaging films or protective pads, during handling and storage.

Regularly clean and maintain processing equipment and tools to keep their surfaces clean.

Inspect and clean embossing rollers or molds to ensure their surfaces are smooth and undamaged.

2. Uneven Patterns

Causes:

Uneven pressure from the embossing rollers.

Inconsistent material thickness.

Unstable processing speed.

Solutions:

Adjust the pressure of the embossing rollers to ensure even application on the material surface.

Check and ensure uniform thickness of the aluminum sheet material.

Adjust processing equipment to maintain a stable processing speed.

3. Material Deformation

Causes:

Uneven heating of the material during processing.

Excessive pressure from the embossing rollers.

Quality issues with the material itself.

Solutions:

Control processing temperature to ensure even heating of the material.

Adjust the pressure of the embossing rollers to avoid excessive pressure causing deformation.

Select high-quality aluminum sheet materials with good processing performance.

4. Surface Oxidation

Causes:

High humidity in the processing environment.

Material surface not cleaned promptly.

Improper storage conditions.

Solutions:

Control the humidity in the processing environment to prevent surface oxidation of the material.

Clean the material surface promptly after processing to remove stains and grease.

Store materials in a dry environment and use moisture-proof measures, such as vacuum packaging or desiccants.

5. Inconsistent Embossing Depth

Causes:

Improper pressure adjustment of the embossing rollers.

Inconsistent material hardness.

Unstable equipment operation.

Solutions:

Regularly calibrate the pressure adjustment system of the embossing rollers to ensure accuracy.

Check and ensure uniform hardness of the materials.

Maintain processing equipment to ensure stable operation.

6. Pattern Wear

Causes:

Poor quality embossing rollers or molds.

Prolonged use without maintenance.

Excessive processing speed.

Solutions:

Choose high-quality embossing rollers or molds.

Regularly maintain and replace embossing rollers or molds to keep them in good condition.

Adjust processing speed to prevent excessive wear of the patterns.

Заключение

In processing embossed aluminum sheets, issues such as surface scratches, uneven patterns, material deformation, surface oxidation, inconsistent embossing depth, and pattern wear may occur. These issues not only affect the appearance and quality of the product but also reduce production efficiency. By taking appropriate preventive and corrective measures, such as adjusting equipment parameters, selecting high-quality materials, and regularly maintaining equipment, it is possible to effectively reduce these problems and ensure high-quality production of embossed aluminum sheets.

Continuous optimization of processing techniques and equipment, as well as enhancing the skill levels of operators, are crucial for ensuring the quality of embossed aluminum sheets. A comprehensive understanding and addressing of various processing issues will lead to better results and higher product quality in actual production.