Aluminum strips are versatile materials used in various industries for a wide range of applications. When selecting aluminum strips, several factors need to be considered to ensure they meet your specific requirements. Here’s a comprehensive guide on how to choose aluminum strips effectively

Determine the Application

Before choosing aluminum strips, identify the specific application they will be used for. Whether it’s for construction, automotive, packaging, or another industry, understanding the application’s requirements will help narrow down your options.

Consider Alloy and Temper

Aluminum strips come in different alloys and tempers, each offering unique properties suited for specific applications. Consider factors such as strength, corrosion resistance, formability, and conductivity when selecting the appropriate alloy and temper for your needs.

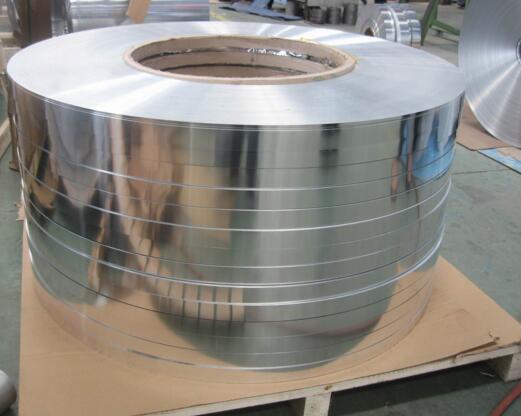

Evaluate Thickness and Width

Aluminum strips are available in various thicknesses and widths to accommodate different requirements. Determine the thickness and width needed for your application based on structural requirements, dimensional specifications, and processing capabilities.

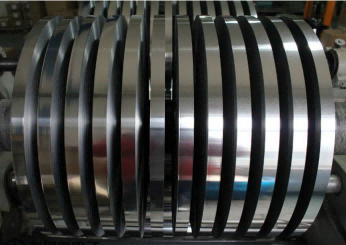

Assess Surface Finish

The surface finish of aluminum strips can vary, ranging from mill finish to polished or coated finishes. Consider the desired aesthetic appearance, surface smoothness, and protection requirements when selecting the appropriate surface finish for your application.

Review Mechanical Properties

Evaluate the mechanical properties of the aluminum strips, including tensile strength, elongation, and hardness. Choose aluminum strips with mechanical properties that match the demands of your application, ensuring optimal performance and durability.

Check for Surface Defects

Inspect the surface of the aluminum strips for any defects such as scratches, dents, or surface irregularities. Ensure that the strips are free from defects that may affect their performance or appearance in your application.

Verify Compliance and Certification

Ensure that the aluminum strips meet relevant industry standards and certifications for quality and safety. Look for products that comply with international standards such as ASTM, EN, or ISO to ensure they meet your requirements.

Consider Cost and Budget

Evaluate the cost of the aluminum strips and consider your budget constraints. Balance the desired quality and performance with budgetary considerations to find the most cost-effective solution for your application.

Review Supplier Reputation

Choose a reputable supplier or manufacturer with a track record of delivering high-quality aluminum strips. Research customer reviews, testimonials, and certifications to assess the supplier’s reliability, customer service, and product quality.

Evaluate Environmental Impact

Consider the environmental impact of the aluminum strips, including their recyclability and sustainability. Choose aluminum strips that are recyclable and manufactured using environmentally friendly processes to minimize your carbon footprint.

By following these guidelines, you can effectively choose aluminum strips that meet your specific requirements, ensuring optimal performance and durability in your application. Whether it’s for construction, automotive, packaging, or any other industry, selecting the right aluminum strips is essential for achieving success in your project.