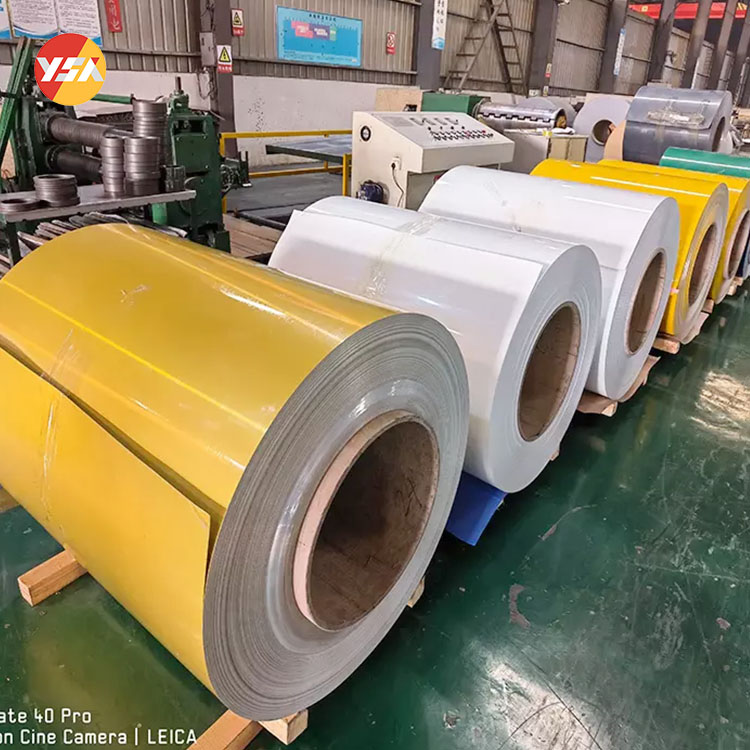

Color aluminum coils, widely used in construction, home appliances, and transportation, often come at a higher price compared to regular aluminum coils. The increased cost can be attributed to several key factors.

Complex Production Process

The production of color-coated aluminum coils involves multiple steps, including surface pretreatment, coating application, and baking. Each step requires precise control and high-quality materials to ensure the coating’s adhesion, weather resistance, and appearance. These additional processes and technical demands increase production costs.

High-Quality Raw Materials

Manufacturing color-coated aluminum coils requires premium aluminum substrates and coating materials. The aluminum substrate must have excellent mechanical properties and surface flatness, while the coating materials need superior weather resistance, corrosion resistance, and color stability. The higher cost of these premium raw materials directly contributes to the higher price of color-coated aluminum coils.

Strict Quality Control

Ensuring the quality of color-coated aluminum coils involves rigorous quality control measures. These include testing coating thickness, color consistency, adhesion, and weather resistance. These quality control processes necessitate high-precision testing equipment and skilled personnel, further adding to production costs.

Market Demand and Applications

Color-coated aluminum coils are extensively used in architectural facades, roofs, ceilings, and window frames, where both aesthetic appeal and durability are crucial. The need for materials that meet high standards of appearance and performance leads to strong market demand. This demand, combined with the supply constraints, drives up prices.

Environmental and Safety Requirements

With increasing environmental awareness and stricter regulations, the production of color-coated aluminum coils must meet higher environmental and safety standards. For instance, coating materials need to have low VOC (volatile organic compounds) content to minimize environmental impact. Additionally, measures to reduce wastewater and exhaust emissions during production also increase costs, reflecting in the product’s price.

Investment in Technology and Research

To enhance the performance and quality of color-coated aluminum coils, manufacturers invest significantly in technology and research. These investments include developing new materials, improving production processes, and upgrading manufacturing equipment. The costs associated with these technological advancements are ultimately reflected in the product pricing.

Заключение

The higher cost of color-coated aluminum coils can be attributed to their complex production process, high-quality raw materials, strict quality control, market demand, environmental and safety requirements, and substantial investments in technology and research. Despite their higher price, the superior performance and wide range of applications make color-coated aluminum coils an essential material in many industries.