Embossed aluminum is an aluminum product with various patterns on the surface after rolling. It is widely used, mainly in packaging, construction, curtain walls and other aspects. Unlike smooth aluminum, embossed aluminum offers greater durability and corrosion resistance because the textured surface helps hide minor scratches and scuffs.

Embossed aluminum sheets have 1000 series, 3000 series, 5000 series and 6000 series aluminum alloy products, including 1060, 3003, 5052 and 6061 embossed aluminum plates. There are many types of products to meet the needs of different customers. All series of embossed aluminum plates have good corrosion resistance, excellent welding performance, high strength, good formability and easy processing.

Top 6 Reasons to Use Embossed Aluminum Sheet

Superior Slip Resistance And Safety

The textured surface of embossed aluminum sheets provides exceptional traction, reducing accident risks in wet or oily environments. For example:

- Industrial Flooring: Factories, oil rigs, and loading docks.

- Transportation: Truck beds, aircraft stairs, and marine gangways.

- Public Spaces: Stair treads, ramps, and pool decks.

Lightweight Yet Durable

Aluminum weighs ~2.7 g/cm³—one-third the density of steel—making it easier to handle and install. Despite its lightness, embossed aluminum offers:

- Corrosion Resistance: Naturally forms an oxide layer to resist rust.

- High Strength-to-Weight Ratio: Ideal for structural applications.

- Longevity: Lasts decades with minimal maintenance.

Especially alloy 3003-H14 embossed sheets are perfect for outdoor use due to their manganese-enhanced durability.

Aesthetic Versatility

Embossed aluminum isn’t just functional—it elevates designs. Architects use textures to:

- Create visual interest on walls, ceilings, or facades.

- Mimic natural materials (e.g., wood grain or stone).

Cost-Effectiveness

Compared to stainless steel or copper, embossed aluminum delivers similar performance at 40–60% lower costs. Benefits include:

- Lower Transportation Costs: Reduced weight cuts shipping fees.

- Minimal Maintenance: No painting or anti-rust treatments needed.

- Recyclability: Aluminum retains 95% of its value post-recycling.

Eco-Friendly Material

Embossed aluminum supports sustainability through:

- Recyclability: Infinitely recyclable without quality loss.

- Energy Efficiency: Requires 95% less energy to recycle than to produce anew.

- LEED Compliance: Contributes to green building certifications.

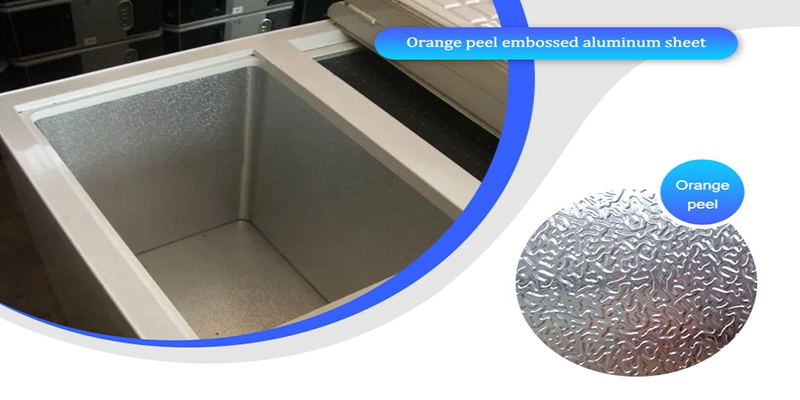

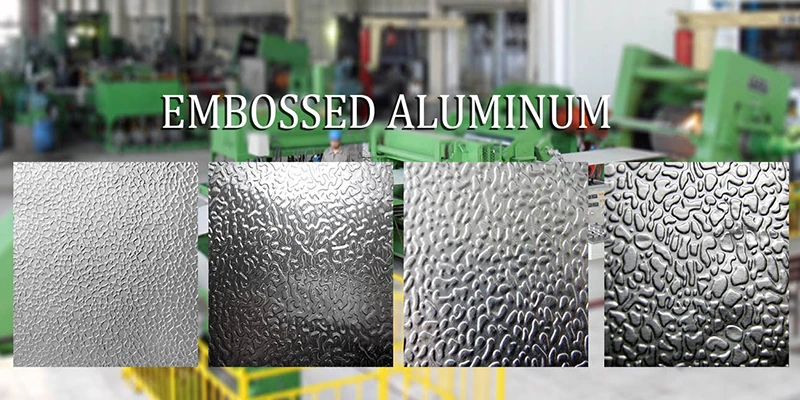

Types of Embossed Aluminum Patterns

| Узоры | Uses | Benefits |

| Diamond Plate | Truck beds, walkways | Slip-resistant, ultra-durable |

| Stucco | Wall panels, elevators | Elegant, scratch-hiding |

| Wood Grian | Furniture, interior decor | Mimics natural wood visually |

| Wood Grain | Ventilation grilles, balustrades | Airflow + artistic design |

| Grooved | Elevator interiors, partitions | Modern, minimalistic texture |

How To Choose The Right Embossed Aluminum Sheet

Select The Right Alloy

| Сплав | Свойства | Best For |

| 1100 | High formability, excellent conductivity | Decorative art, electronics |

| 3003 | Manganese-enhanced strength, corrosion-resistant | Outdoor cladding, roofing |

| 5052 | Superior weldability, marine-grade | Boat building, chemical tanks |

Gauge Thickness Guidelines

- 0.040″–0.063″ (20–16 gauge) → Decorative panels, signage.

- 0.080″–0.125″ (12–10 gauge) → Flooring, truck beds.

- 0.188″+ (3/16″ and up) → Heavy-duty industrial surfaces.

Pattern Considerations

- Diamond Plate: Maximum slip resistance.

- Stucco: Subtle grip for decorative walls.

FAQs of Embossed Aluminum

Q1: Can embossed aluminum be painted?

Yes! Use etching primer and acrylic paints for lasting adhesion.

Q2: Is it suitable for high-temperature environments?

Aluminum melts at 660°C (1220°F), but anodized grades withstand up to 200°C (392°F).

Q3: How long does embossed aluminum last outdoors?

Properly alloyed sheets (e.g., 3003) can last 50+ years without rusting.

Q4: Can I weld embossed aluminum sheets?

Yes, but choose weldable alloys like 5052 or 6061 and use TIG/MIG methods.