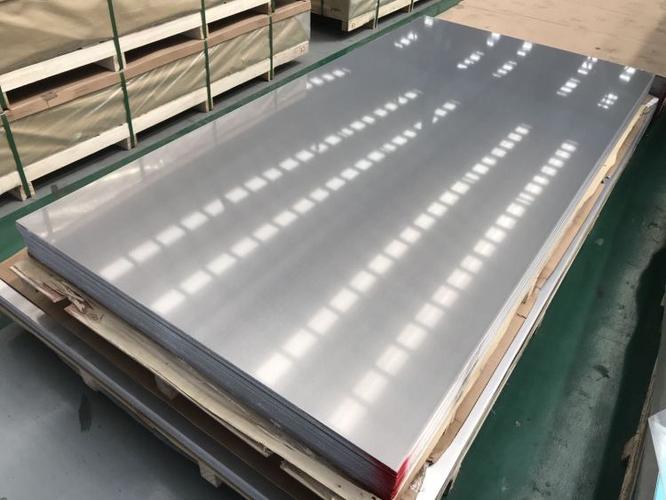

1060 aluminum plate belongs to industrial pure aluminum plate. Used for electronic components, lamp holders, fan blades, signs, kitchenware, panels, cabinets, reflective devices, automotive accessories, decorations, industrial products, etc. Width 800mm-2200mm, size can be customized according to needs.

Low density

The density of aluminum and aluminum alloys is close to 2.7g/, which is about one-third of that of iron or copper. Aluminum and aluminum alloys have high strength. After a certain degree of cold processing, the strength of the matrix can be strengthened, and some grades of aluminum alloys can also be strengthened through heat treatment.

Good conductivity and thermal conductivity

Aluminum’s conductivity and thermal conductivity are second only to silver, copper, and gold.

Easy to process

After adding certain alloying elements, cast aluminum alloys with good casting performance or deformed aluminum alloys with good processing plasticity can be obtained. The 1060 aluminum plate is lightweight, has high tensile strength, good elongation performance, and high recovery residual value. Good craftsmanship, using the process of processing first and then painting, aluminum plates can be processed into various complex geometric shapes such as flat, arc, and spherical shapes. Aluminum plates are formed in the factory and do not require cutting, allowing for direct secondary processing.

Good corrosion resistance of 1060 aluminum plate

The surface of 1060 aluminum plate is prone to naturally produce a dense and sturdy AL2O3 protective film, which can effectively protect the substrate from corrosion. By artificial anodizing and coloring, cast aluminum alloys with good casting performance or deformed aluminum alloys with good processing plasticity can be obtained.

6061 aluminum alloy heat treatment can strengthen the alloy, with good formability, weldability, and machinability.

1. It has excellent processing performance, good corrosion resistance, high toughness, no deformation after processing, easy coating, and good oxidation effect, and can still maintain good operability after annealing;

2. There is no tendency for stress corrosion cracking, and it has excellent weldability and good cold workability;

Magnesium aluminum 6061-T651 is the main alloy of the 6-series alloy, which is a high-quality aluminum alloy product that has undergone heat treatment and pre stretching process; Magnesium aluminum 6061 has excellent processing performance, good corrosion resistance, high toughness, no deformation after processing, easy coloring film, and excellent oxidation effect.

Main use: Widely used in various industrial structural components that require certain strength and high corrosion resistance, such as manufacturing trucks, tower buildings, ships, trams, and railway vehicles.