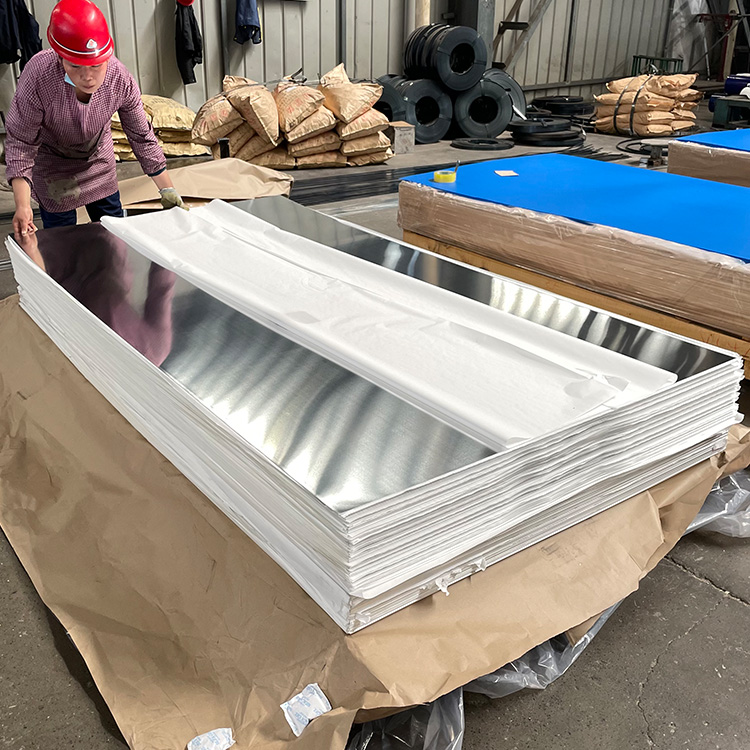

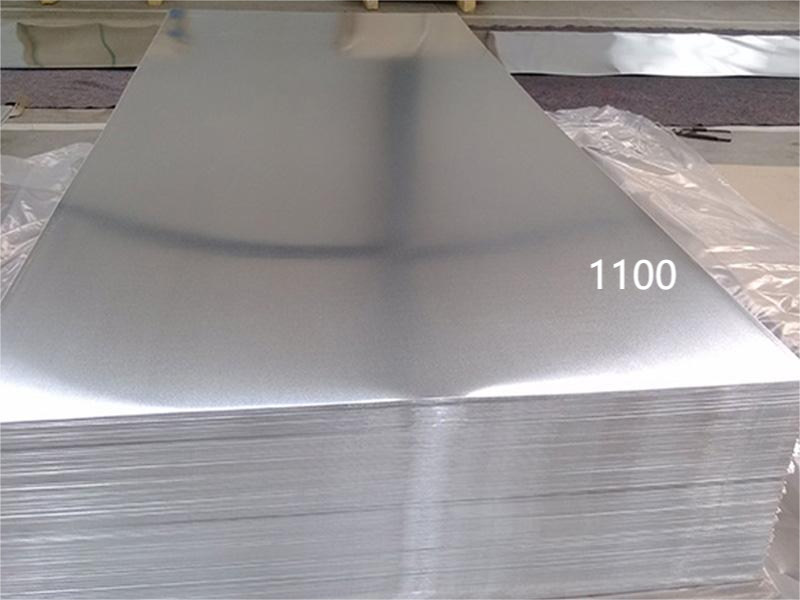

In recent years, aluminum plate, as a lightweight, durable, easy to process materials, is widely used in construction, transportation, electrical appliances and other fields. Among them, 1100 aluminum plate and 1060 aluminum plate are the two common types of differences in aluminum content, Çekme Dayanımı, specifications and other aspects, which are introduced in detail below.

Aluminum content

The aluminum content of 1100 is 99.00%, while 1060 is 99.60%. Generally speaking, the higher the aluminum content, the aluminum plate is relatively soft, so the 1100 aluminum plate is slightly harder than the 1060 aluminum plate.

Tensile strength of 1100 and 1060 aluminum plate

The tensile strength of 1100 is slightly higher than 1060. The tensile strength of 1100 aluminum plate is 110-136, while the tensile strength of 1060 aluminum plate is 95-110. Therefore, it is recommended to use 1100 aluminum plates where high strength is required.

Teknik Özellikler

1100 aluminum plate relative to 1060 aluminum plate, inventory material specifications, wide width, can be leveled into 3 meters, 4 meters, 6 meters, 8 meters, etc., so when choosing the aluminum plate specifications, 1100 aluminum plate can be selected according to the required specifications.

Application area

1100 aluminum plate is mainly used for curtain wall aluminum sheet, radiator, printing plate, heat exchanger parts, etc., can be punched, bent, welding and other processing. And 1060 aluminum plate is mainly used for signs, billboards, building appearance decoration, vehicle body, low strength of products such as kitchen sink, lamp holder, etc. Therefore, when selecting the aluminum plate, it needs to be selected according to the use scenario and requirements.

In short, the 1100 aluminum plate and the 1060 aluminum plate have their own characteristics, and the selection needs to be compared according to the specific requirements. For other types of aluminum plates, similar comparisons are required to select the most suitable material.