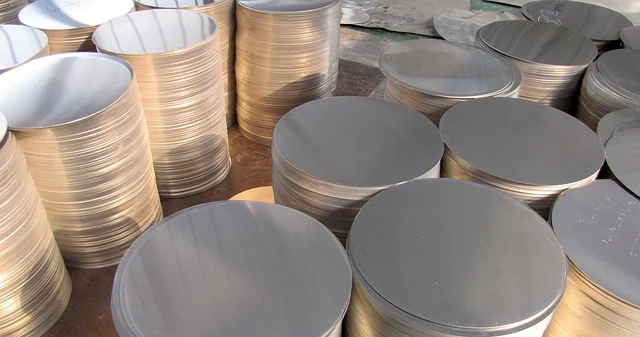

3000 series aluminum discs are aluminum materials supplied in disc shape. Compared with 3 series aluminum sheets and aluminum coils, aluminum discs have a wider range of applications and are suitable for various shapes and designs. This series of aluminum alloys are mainly composed of aluminum and manganese elements. Whether it is aluminum plates, aluminum coils, aluminum discs, aluminum strips, etc., the 3000 series is the most popular alloy series. This article will focus on introducing you to the advantages, uses, manufacturing processes and maintenance recommendations of aluminum 3000 series discs.

3000 series aluminum circles are a special aluminum alloy series. 3 series aluminum circles are usually used in home decoration. From the physical and chemical properties of aluminum discs, it can be seen that the weld ability of this type of aluminum discs is relatively strong, and the strength is not lower than that of ordinary metals, and most importantly, the price of 3000 aluminum series discs is not too high.

Common Alloys In The 3000 Series:

3003 Aluminum Circle:

1. Features and Applications

3003 aluminum circles are known for their exceptional corrosion resistance, making them a popular choice for cookware, food processing equipment, and architectural elements.

2. Examples of Uses

Examples of applications include cooking pots, pan bottoms, heat exchangers, and chemical handling equipment.

3004 Aluminum Circle:

1. Characteristics and Advantages

3004 alloy aluminum circles are admired for their high strength and good formability. They are commonly used in the production of beverage cans and industrial tanks.

2. Industrial Applications

Applications include beverage cans, fuel tanks, and pressure vessels.

3105 Aluminum Circle:

1. Unique Properties

3105 alloy aluminum circles are celebrated for their ease of painting and printing. They are frequently employed in the production of road signs and traffic signals.

2. Utilization in Manufacturing

You’ll find these circles in road signs, license plates, and other traffic-related signage.

Advantages of 3000 Series Aluminum Circles

- Korozyon direnci.

- Formability and drawing depth.

- Thermal conductivity.

- Lightweight and durable.

- Various surface treatment options.

3000 Series Aluminum Circles Common Applications

- Cookware and Kitchen Utensils

3000 aluminum series circles find extensive use in the production of cookware and kitchen utensils. Their excellent heat conductivity allows for uniform heat distribution during cooking. The circles’ formability enables the creation of complex shapes, such as pots, pans, and lids, to cater to various culinary needs. While 1060 aluminum circles are a popular choice for cookware, 3003 aluminum circles discs are preferred for high-end rice cookers because they last longer.

- Lighting Fixtures and Reflectors

Due to their excellent formability and reflectivity, 3000 aluminum series circles are commonly used in lighting fixtures and reflectors. These circles allow for the efficient redirection and dispersion of light, ensuring optimum illumination. Their corrosion resistance protects against environmental factors, making them suitable for both indoor and outdoor lighting applications.

- Signage and Advertising Panels

In the world of signage and advertising, 3000 series aluminum circles are valued for their aesthetic appeal, durability, and versatility. These circles serve as the base material for signage boards, display panels, and outdoor advertising structures. The circles can be customized with different finishes and coatings to achieve desired visual effects and withstand outdoor exposure.

- Heat Exchangers and Radiators

In various heating and cooling systems, such as HVAC equipment and radiators, alloy 3000 series aluminum circles play a crucial role. Their high thermal conductivity ensures effective heat transfer, promoting efficient temperature regulation. The circles’ formability allows for the creation of intricate tube designs, optimizing heat exchange performance.

Manufacturing Process:

The manufacturing of alloy 3000 series aluminum circles involve several key steps to ensure quality and consistency. The process starts with melting and casting the aluminum alloy, followed by rolling and annealing to obtain the desired thickness and mechanical properties. Cold working techniques, such as cold rolling or cold drawing, are utilized to enhance the circles’ formability and dimensional accuracy. Finally, the circles are cut to the desired diameter and undergo surface treatments, such as polishing or coating, to meet specific requirements.

Factors to Choose 3000 Series Aluminum Circles:

When selecting 3000 series aluminum circles discs for a particular application, several factors should be taken into account:

Application Requirements and Performance Expectations

Understanding the specific needs of the intended application is crucial. Consider factors such as required strength, corrosion resistance, formability, and heat transfer properties. Match these requirements with the appropriate 3000 series aluminum circles variant to ensure optimal performance. Like the common 3003 aluminum discs, which has moderate strength, 3105 aluminum circles and 3004 aluminum circles have relatively high strength and corrosion resistance; 3105 aluminum is not as good as 3003 aluminum discs and 3004 aluminum discs in having good formability.

Thickness and Diameter Selection

The thickness and diameter of the circles should align with the design specifications and application demands. Thicker circles offer increased strength, while thinner circles provide enhanced formability. Diameter selection affects the size and functionality of the end product.

Surface Finish and Coating Options

Consider the desired appearance, functionality, and environmental conditions of the application. Explore available surface finishes, such as mill finish, anodizing, or powder coating, to achieve the desired aesthetics, corrosion resistance, and durability.

Cost and Budget Considerations

Evaluate the overall cost-effectiveness of utilizing alloy 3000 series aluminum circles for the intended application. Consider factors such as the initial material cost, processing costs, and long-term maintenance expenses. It is important to balance performance requirements with budget constraints.

Proper Handling, Storage, and Maintenance Guidelines

Proper handling, storage, and maintenance practices ensure the longevity and performance of 3000 series aluminum circles.

Handling Precautions During Transportation and Fabrication

During transportation or fabrication, avoid excessive rough handling or impact that may cause surface scratches or deformations. Use appropriate protective measures, such as cushioning materials or racks, to prevent physical damage.

Storage Recommendations to Prevent Surface Damage and Contamination

Store 3000 series aluminum circles in a clean, dry, and well-ventilated area. Maintain a controlled environment to prevent exposure to moisture or aggressive chemicals that can cause surface corrosion. Proper stacking, separation, and covering techniques help prevent dust, dirt, or other contaminants from settling on the circles’ surfaces.

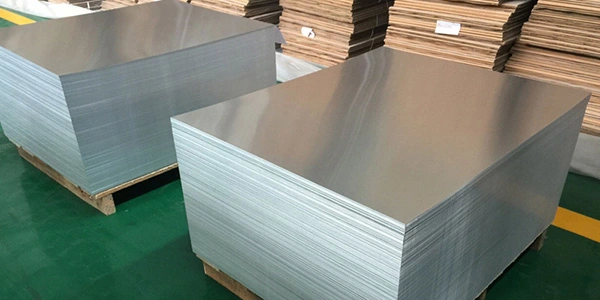

Responsible Sourcing And Supply Chain Practices

Responsible sourcing practices ensure the ethical and sustainable extraction of raw materials for 3000 series aluminum circles. Industries can prioritize suppliers that comply with environmental regulations and prioritize social responsibility. Transparent supply chain practices help trace the origins of the material and ensure adherence to sustainable practices throughout the production process. Yongsheng Aluminum has different forms of 3000 aluminum alloys such as 3000 series aluminum sheets plates, 3000 series aluminum circles discs, 3000 series aluminum foil, 3000 series aluminum coils, and 3000 series aluminum strips. Welcome to leave a message below to ask about your needs.

SSS:

How Do You Harden 3003 Aluminum?

Solution treatment: by heating 3003 aluminum to a certain temperature and then cooling it quickly. Its processing temperature and time need to be adjusted according to the specific situation.

Cold deformation processing: After cooling aluminum 3003, it is deformed at room temperature through processing methods such as rolling, cold drawing or cold rolling. To increase the resistance between crystals and thus increase the hardness.

Precipitation hardening: After solution treatment, the hardness is increased by heating and cooling again.

Is Granite Cookware Safe?

Granite cookware is usually made of granite particles and resin, and uses ceramic or non-stick coating as the surface material, which has excellent non-stick properties. But its coating may peel off over time, improper use of sharp objects may cause damage to the coating, and the resin part of granite cookware may also release harmful gases at high temperatures. In comparison, aluminum alloy cookware can be compounded with stainless steel materials, has good thermal conductivity, is suitable for high temperature or fried dishes, is durable and can withstand normal wear and tear.

How To Organize Aluminum Kitchen Utensils?

First classify similar utensils, such as pots, cutlery, baking utensils, etc., then classify each kitchen utensil according to the size and shape, and then choose appropriate storage space such as cabinets or kitchen shelves, use drawer dividers, storage baskets or hooks and other organizational tools to keep them organized and in place. For items with long handles or items that are prone to collision, consider using independent hooks or magnetic strips to hang or secure them. Make sure utensils are dry when stored to prevent problems such as metal corrosion.