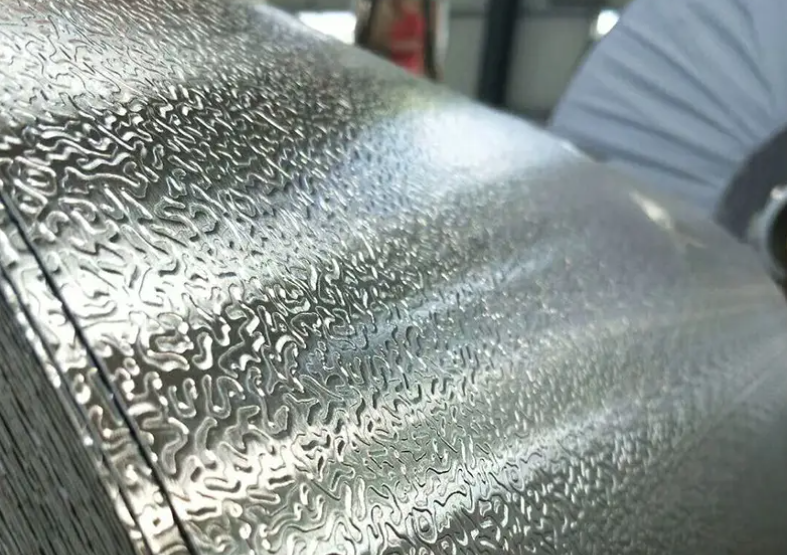

Embossed insulated aluminum sheet is a material that combines excellent thermal insulation properties, aesthetic appeal, and good workability. Due to its unique embossed surface texture and outstanding physical characteristics, this material is widely used across various industries. Below, we will delve into its primary application fields and the advantages it brings.

Construction Industry

In modern construction, embossed insulated aluminum sheet is commonly used for exterior wall cladding and insulation materials. Its excellent thermal insulation properties effectively reduce energy consumption, helping to maintain stable indoor temperatures. This material is often used in conjunction with other building materials, forming efficient insulation systems. Additionally, the diverse surface designs of embossed aluminum sheet enhance the aesthetic quality of buildings, making it an essential element in contemporary architectural design.

– Energy Efficiency: Buildings that utilize this material not only lower energy consumption but also reduce environmental impact, aligning with sustainability goals.

– Diverse Aesthetic Designs: The embossed surface provides a unique appearance, enhancing a building’s visual appeal and overall value.

Aerospace Industry of Embossed Insulated Aluminum Sheet

In the aerospace sector, embossed insulated aluminum sheet is valued for its exceptional lightweight characteristics and high-temperature resistance. It is widely used in aircraft components, such as outer shells and insulation layers, to ensure stable temperatures during high-altitude flights, thereby ensuring flight safety. Moreover, this material’s lightweight nature helps reduce overall weight, improving fuel efficiency.

– Enhanced Flight Safety: The effective insulation prevents overheating, which could lead to material deformation or damage.

– Fuel Savings: Reducing weight not only improves payload capacity but also lowers fuel consumption, cutting operational costs.

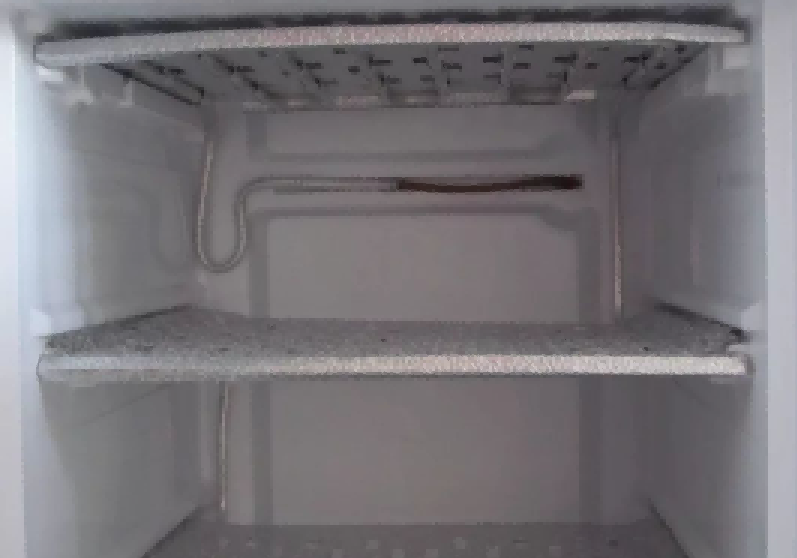

Refrigeration Equipment

In the manufacturing of refrigeration equipment, embossed insulated aluminum sheet is commonly used in the shells and inner walls of refrigerators, freezers, and air conditioners. Its superior insulation performance minimizes heat transfer, thereby enhancing cooling efficiency and reducing energy use. These applications allow consumers to benefit from more effective cooling solutions and lower electricity bills.

– Reduced Heat Loss: Effective insulation maintains low temperatures over extended periods, prolonging the freshness of food and beverages.

– Energy Efficiency: With increasing energy efficiency standards, equipment utilizing embossed aluminum sheet can more easily comply with regulations, gaining a competitive edge in the market.

Food Packaging

In the food packaging industry, embossed insulated aluminum sheet is utilized for high-speed frozen foods, thermal meal containers, and insulated cups. Due to its excellent thermal insulation properties, this type of packaging effectively maintains food temperatures and extends freshness, thereby reducing spoilage risks. Additionally, the embossed surface design enhances the visual appeal of products, increasing consumer purchasing interest.

– Food Safety Assurance: Insulation prevents temperature fluctuations that could lead to bacterial growth, ensuring food safety.

– Innovative Visual Effects: Attractive packaging designs can captivate consumers, helping products stand out in a competitive market.

Automotive Manufacturing

In the automotive industry, embossed insulated aluminum sheet is increasingly used in vehicle interior components, insulation layers, and engine hoods. This material not only enhances overall aesthetics but also effectively blocks engine noise and heat, improving passenger comfort. Furthermore, the lightweight characteristic of embossed aluminum sheet helps reduce vehicle weight, improving fuel economy and aligning with modern consumer demands for eco-friendliness and efficiency.

– Increased Passenger Comfort: The insulation properties help maintain cabin temperature and reduce external noise, enhancing the riding experience.

– Supporting Environmental Goals: The trend toward lightweight materials in the automotive industry aligns perfectly with the characteristics of embossed aluminum sheet.

Home Appliances

In the production of home appliances, embossed insulated aluminum sheet is widely used in the outer shells of washing machines, water heaters, and microwaves. It not only provides excellent insulation but also enhances the modern aesthetic appeal of appliances, meeting consumer design expectations. The durability and corrosion resistance of this material also ensure reliability during use.

– Combining Beauty and Durability: The embossed design enhances the appearance while providing scratch resistance, extending the product lifespan.

– Market Competitiveness: Products that integrate functionality and aesthetic appeal are more likely to attract consumers, boosting market competitiveness.

Artistic and Decorative Items

The unique appearance of embossed insulated aluminum sheet also shows potential in artistic creation and decorative item production. Designers leverage its malleability and adaptability to create distinctive art pieces and home decor, infusing spaces with artistic charm.

– Enriching Artistic Atmosphere: The embossed design allows decorative items to exhibit a variety of textures and effects, making spaces more dynamic and interesting.

– Attracting Art Enthusiasts: Unique materials and designs attract many art lovers and consumers, enhancing the market value of artistic creations.

Sonuç

Embossed insulated aluminum sheet, with its outstanding thermal insulation properties, lightweight characteristics, and aesthetic designs, has found widespread application across the construction, aerospace, refrigeration, food packaging, automotive manufacturing, home appliances, and artistic fields. As technology continues to advance and demand for sustainable solutions grows, the application prospects for this material are undoubtedly expansive, leading to more convenience and beauty in our lives.