Cutting a circular disk out of a thin aluminum sheet is a common task in various industries, including manufacturing, construction projects. Whether you need an aluminum circle, aluminum disc, round metal plate, aluminum disk, or round aluminum plate, the process requires precision, the right tools, and proper techniques. This guide will walk you through the steps to achieve a clean and accurate cut.

Understanding Aluminum Sheets

Before diving into the cutting process, it’s essential to understand the material you’re working with. Aluminum is a lightweight, durable, and corrosion-resistant metal, making it ideal for a wide range of applications. Thin aluminum sheets are typically easier to cut than thicker ones, but they still require careful handling to avoid warping or damage.

Types of Aluminum Sheets

- Alüminyum Çember: A pre-cut circular piece of aluminum, often used in manufacturing.

- Aluminum Disc: Similar to an aluminum circle, but may refer to a specific application or thickness.

- Round Metal Plate: A general term for any circular metal plate, including aluminum.

- Aluminum Disk: Another term for a circular piece of aluminum, often used interchangeably with aluminum disc.

- Round Aluminum Plate: A circular aluminum plate, typically used in structural or decorative applications.

Tools and Materials Needed

To cut a circular disk out of a thin aluminum sheet, you’ll need the following tools and materials:

- Aluminum Sheet: Choose the appropriate thickness and size for your project.

- Measuring Tape or Ruler: For accurate measurements.

- Marker or Scrib: To mark the cutting line.

- Compass or Circular Template: To draw a perfect circle.

- Safety Gear: Gloves, safety glasses, and ear protection.

- Cutting Tools: Depending on your preference and the tools available, you can use:

- Jigsaw: Ideal for curved cuts.

- Circular Saw: For straight and curved cuts with a guide.

- Shears: Manual or electric shears for thin sheets.

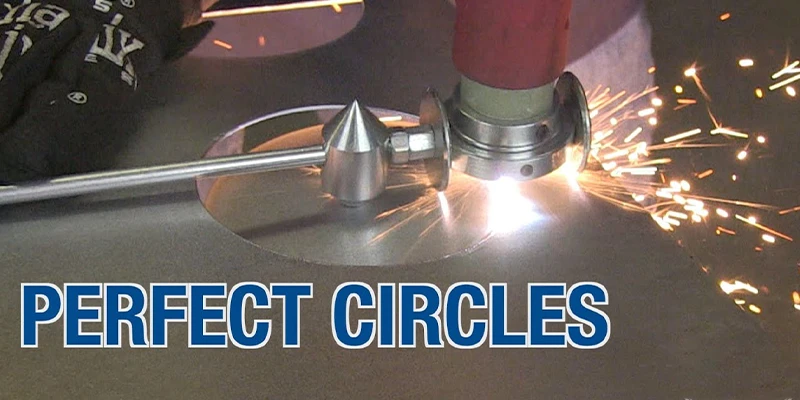

- Plasma Cutter: For precise and fast cuts.

- Laser Cutter: For high-precision cuts in industrial settings.

Step-by-Step Guide to Cutting a Circular Disk

Step 1: Measure and Mark

- Measure the Diameter: Determine the diameter of the aluminum circle or aluminum disc you need. Use a measuring tape or ruler to mark the center point of the circle on the aluminum sheet.

- Draw the Circle: Using a compass or a circular template, draw the circle on the sheet. Ensure the line is clear and visible.

Step 2: Secure the Aluminum Sheet

- Clamp the Sheet: Secure the aluminum sheet to a stable work surface using clamps. This prevents the sheet from moving during the cutting process, ensuring accuracy and safety.

- Use a Cutting Mat: If using a laser cutter or plasma cutter, place the sheet on a cutting mat to protect the work surface.

Step 3: Choose the Right Cutting Tool

Select the appropriate cutting tool based on the thickness of the aluminum sheet and the precision required.

- Jigsaw: Ideal for thin sheets and curved cuts. Use a fine-toothed blade designed for metal.

- Circular Saw: Suitable for thicker sheets. Use a carbide-tipped blade and a guide to ensure a straight cut.

- Shears: Best for thin sheets. Manual shears are suitable for small projects, while electric shears are better for larger ones.

- Plasma Cutter: Perfect for thick sheets and industrial applications. Requires a steady hand and proper safety gear.

- Laser Cutter: Offers the highest precision but is typically used in industrial settings.

Step 5: Smooth The Edges

- Deburr the Edges: After cutting, use a deburring tool or file to remove any sharp edges or burrs. This ensures the round aluminum plate is safe to handle.

- Sand the Edges: For a smoother finish, use fine-grit sandpaper to smooth the edges of the aluminum circle.

Step 6: Inspect And Clean

- Inspect the disk: Check the aluminum disc or round aluminum plate for any imperfections, such as uneven edges or rough spots. If necessary, make additional adjustments using a file or sandpaper.

- Clean the surface: Wipe the aluminum disk with a clean cloth to remove any metal shavings, dust, or debris. If you plan to use the disk for a polished or decorative application, consider using a metal cleaner to enhance its appearance.

Tips For Cutting Aluminum Sheet

Cutting aluminum sheets can be straightforward if you follow these tips:

- Choose the Right Blade or Tool: Ensure the blade or cutting tool is designed for metal. For example, use a fine-toothed blade for a jigsaw or a carbide-tipped blade for a circular saw.

- Slowly and Steadily: Rushing the process can lead to mistakes or uneven cuts. Take your time to ensure precision.

- Use Lubrication: When using power tools like a jigsaw or circular saw, apply a lubricant (such as cutting oil) to reduce friction and prevent the blade from overheating.

- Secure the Sheet Properly: Always clamp the aluminum sheet to a stable surface to prevent it from moving during cutting.

- Wear Safety Gear: Protect yourself with gloves, safety glasses, and ear protection, especially when using power tools.

Alternative Methods for Cutting Aluminum Circles

If you don’t have access to power tools or prefer a different approach, here are some alternative methods:

- Using Tin Snips

Tin snips are manual cutting tools that work well for thin aluminum sheets. While they require more effort, they are effective for small projects.

Process: Mark the circle, then use the snips to make small, controlled cuts along the line. Rotate the sheet as you cut to follow the curve.

- Using a Hole Saw

A hole saw is a cylindrical cutting tool attached to a drill, ideal for creating small circular disks.

Process: Secure the aluminum sheet, attach the hole saw to a drill, and carefully cut out the circle. This method is best for smaller diameters.

- Using a CNC Machine

For industrial or high-precision projects, a CNC (Computer Numerical Control) machine can cut aluminum circles with exceptional accuracy.

Process: Input the dimensions into the CNC machine, and it will automatically cut the aluminum disk or round metal plate to your specifications.

Whether you’re creating an aluminum circle, aluminum disc, round metal plate, aluminum disk, or round aluminum plate, following the steps outlined in this guide will help you achieve a clean and precise result.