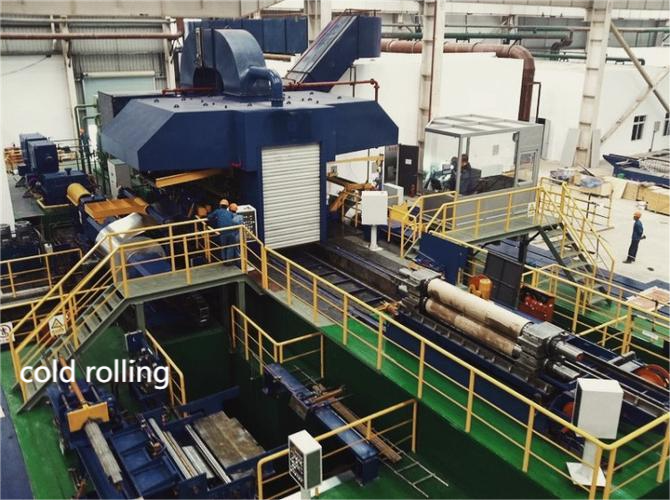

Selection and adjustment of rolling machinery

The basis of cold rolling process is to select suitable rolling machinery and make precise adjustments. Different rolling machines are suitable for different thicknesses and hardness of aluminum sheets, so it is necessary to choose a suitable rolling mill according to product requirements. At the same time, precise adjustment of the rolling mill is required before rolling to ensure the stability and accuracy of the rolling process.

Design and Manufacturing of Rolling Rolls

Rolling rolls are an important component of cold rolling technology, and their design and manufacturing quality have a significant impact on product performance. The material, shape, size and other factors of the rollers need to be fully considered to ensure stability and accuracy during the rolling process.

Selection and Use of Rolling Lubricants

Lubricants are needed during the cold rolling process to reduce rolling force and friction, improve rolling efficiency and product surface quality. Therefore, it is necessary to select suitable lubricants based on product characteristics and process requirements, and strictly control the amount and method of use.

Temperature control during rolling process

During the cold rolling process, temperature control has a significant impact on product performance. Excessive temperature can lead to material deformation and a decrease in surface quality, while too low temperature may cause material cracking and fracture. Therefore, it is necessary to strictly control the temperature during the rolling process and make adjustments as needed.

Yüzey işleme

The surface of cold-rolled aluminum alloy coils may have defects or impurities, and surface treatment is needed to improve the appearance and quality of the product. Common surface treatment methods include grinding, polishing, sandblasting, etc.

Quality inspection

After each production process, strict quality testing is required to ensure that all indicators of the product meet the requirements. The testing content includes size, shape, surface quality, mechanical properties, etc.

The key process and control elements of cold rolling aluminum alloy coils cover multiple aspects, including equipment selection and adjustment, roller design and manufacturing, lubricant selection and use, temperature control, surface treatment, and quality inspection. These links are interrelated and interdependent, requiring comprehensive consideration and careful operation to ensure the quality and performance of the final product.