Aluminum strip plays a crucial role in fin-type transformers, which are widely used in power systems, electronic devices, and various electrical equipment. The primary function of these transformers is to convert voltage and enhance energy transmission efficiency. In this context, aluminum strip stands out due to its unique properties. This article will explore the applications and advantages of aluminum strip in fin-type transformers.

Excellent Conductivity

One of the key benefits of aluminum strip is its conductivity, making it an ideal choice for fin-type transformers. While aluminum has slightly lower conductivity compared to copper, its lightweight and cost-effectiveness compensate for this disadvantage. Transformers primarily function to transfer current between different potentials, and aluminum strip effectively conducts electricity to various transformer components, ensuring optimal performance and high efficiency. By intelligently designing the cross-section of aluminum strip, significant improvements in energy transmission efficiency can be achieved.

Lightweight Design

Aluminum strip is lighter than other materials, especially copper. This lightweight characteristic is crucial in modern device design, as reducing overall weight can minimize transportation and installation costs while also lessening the load on supporting structures. As the demand for lightweight equipment increases, aluminum strip has become the preferred material in many fin-type transformer designs. This quality makes fin-type transformers more competitive in applications requiring improved portability and installation flexibility.

Cost-Effectiveness

From a cost perspective, aluminum strip presents significant advantages. Generally, the production cost of aluminum is lower than that of copper, which helps to significantly reduce the overall production costs of fin-type transformers. Particularly in large-scale production, using aluminum strip can lower unit costs, allowing manufacturers to remain competitive in price-sensitive markets. This cost advantage encourages manufacturers to favor aluminum strip in their designs and production processes.

Excellent Thermal Conductivity in Fin-Type Transformers

The thermal conductivity of aluminum is crucial in applications like fin-type transformers. Its ability to efficiently conduct heat allows for better heat dissipation, which is essential for maintaining optimal operating temperatures. By using aluminum strips, the transformers can effectively release heat, preventing overheating and ensuring safety and stability during operation. This not only helps in achieving reliable performance but also contributes to the longevity of the equipment.

Versatility

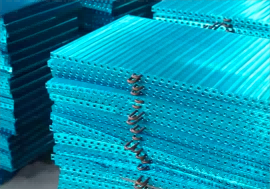

Aluminum strip can be produced in various thicknesses and widths to meet different product requirements. This versatility allows it to suit a wide range of transformer specifications, from small devices to large power transformers. In addition to its basic functionality, aluminum strip can undergo various surface treatments, such as anodizing, enhancing its corrosion resistance and prolonging its lifespan in diverse environments.

Ease of Processing and Manufacturing

The processing of aluminum strip is relatively straightforward, making it easy to shape through stamping, bending, and various other methods. This flexibility enables designers to optimize their designs based on specific needs, enhancing the overall performance of the product. Whether in large-scale or custom small-batch production, the ease of processing aluminum strip is a significant advantage in the manufacturing process.

Conclusion

In summary, the application of aluminum strip in fin-type transformers not only improves energy transmission efficiency but also enhances the competitiveness and stability of the equipment through its lightweight nature, cost-effectiveness, and excellent thermal properties. As technology continues to advance and the demand for high-performance transformers grows, the future of aluminum strip will expand even further. This material will continue to drive innovation and progress in electrical equipment.