Giriş:

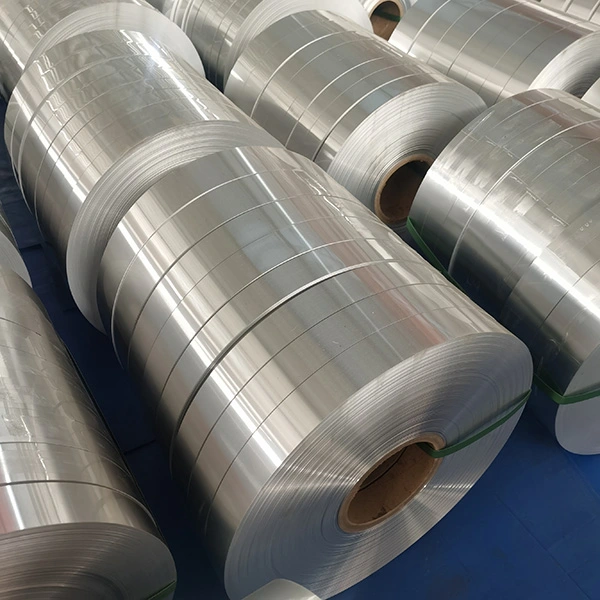

Aluminum strip is a deep-processing product of aluminum formed by cutting aluminum coils. The raw materials for aluminum strips are mainly pure aluminum, hot-rolled aluminum coils or aluminum alloy cast-rolled aluminum coils. These raw materials are put into cold-rolled aluminum coils. The thin-plate aluminum coils of different thicknesses and widths are rolled in the machine, and then the aluminum coils are put into the slitting machine for longitudinal slitting, and after slitting, aluminum strips of different widths are formed.

The so-called slitting refers to the process of cutting wide alüminyum bobinler into narrower strips. It enables suppliers to meet customer-specific requirements for strip width, thickness and surface quality. The choice of slitting method depends on a variety of factors, including desired strip size, material properties, throughput, cost considerations, and any special requirements. So, do you know what is the cutting method of the aluminum strip supplier?

Commonly Used Cutting Methods:

Rotary Shear Slitting

Rotary shear slitting is a common method used in the aluminum strip industry. Aluminum coils are cut into strips by using circular blades mounted on rotating drums. Rotary shear slitting provides precise, clean cuts, making it suitable for high-quality strip production. It is especially effective for thin and soft aluminum materials, especially 1000 series aluminum strips: 1050 aluminum strip, 1060 aluminum strip, 1100 aluminum strip, etc.

Loop Cutting

Ring cutting is when a ring is formed in the aluminum coil, which is then passed through a set of knives to cut the coil into strips. Circular slitting is known for its high efficiency and high-speed operation, suitable for high-volume production. It is usually used for thicker aluminum strips.

Scissors Cutting

Scissors slitting is a general purpose slitting method that utilizes two rotating circular knives to cut aluminum coils. The knives move in opposite directions, creating a scissor-like cutting action. Scissor slitting offers the flexibility to handle a wide range of strip widths and is typically used for medium to heavy aluminum strip.

Razor Cutting

Razor slitting involves cutting aluminum coils into strips using a sharp blade. The method has excellent precision and is suitable for narrower strip widths. Razor slitting is typically used on thin, delicate aluminum materials where clean, burr-free edges are required.

Crushing And Slitting

Extrusion slitting is a method of compressing a coil of aluminum between two hard surfaces while cutting the compressed area with a circular knife. This method of slitting is typically used for thicker aluminum strips and allows for good control of the cutting process. It is suitable for materials where there may be variations in thickness or surface quality.

Laser Slitting

Laser slitting utilizes a high powered laser beam to cut aluminum coils. This method provides excellent precision and allows complex cutting patterns. Laser cutting is ideal for thin and delicate aluminum materials as it eliminates the risk of mechanical stress or deformation during the cutting process.

Diamond Cutting

Diamond cutting involves cutting aluminum coils into strips using a diamond-coated blade. Diamond coating ensures durability and precision, making it suitable for high-quality strip production. Diamond cutting is usually used for thin and soft aluminum materials.

Turret Cutting

Turret slitting is a method that utilizes sets of circular knives mounted on a rotating turret. The aluminum coil passes through the turret, and each set of knives cuts the aluminum coil into strips of different widths. Turret slitting has high flexibility and efficiency, suitable for producing strips of different sizes.

Crushing And Slitting

Crushing and scoring slitting combines the crushing and scoring method with a scoring mechanism. The scoring mechanism forms a partial cut on the surface of the aluminum coil, and then the crushing and slitting process completes the cut. This method is suitable for materials that require easy tearing or controlled splitting.

Slitting And Trimming Slitting

Slitting and trimming slitting refers to cutting the edges of the aluminum coil to remove any irregularities or burrs before cutting it into strips. This method ensures clean and smooth edges, which improves the overall quality of the final strip. Slitting and edge slitting are often used for high-precision applications where edge quality is critical. Yongsheng usually uses a slitting machine to cut the metal strip longitudinally, and rewinds the slit narrow strip into a roll, which is more convenient to operate, high in cutting quality, and high in material utilization.

Advantages Of Yongsheng Popular Aluminum Strips:

1050 aluminum strip is a product in the pure aluminum series 1050 aluminum strip has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but low strength, no strengthening through heat treatment, poor cutting performance, acceptable contact welding ,gas welding The production process is relatively single and the price is relatively cheap It is the most commonly used series in the conventional industry.

1060 aluminum strip has the characteristics of flat surface, high cleanliness, suitable for polymer welding, and product elongation, tensile strength, fully able to meet the conventional processing requirements (punching, drawing) high formability, is widely used in soft batteries connections, aluminum-plastic panels, channel letter, signs, and other fields.

3003 aluminum strip is AL-Mn alloy, which is the most widely used rust-proof aluminum and can not be strengthened by heat treatment Therefore, it adopts cold processing method to improve its mechanical properties; in the annealed state, it has high plasticity and is semi-cold-hardened When the plasticity is still good, cold work hardening low plasticity, good corrosion resistance, good weldability, poor cutting performance

Bu 5052 aluminum strip belongs to the Al-Mg series alloy and has a wide range of applications and is the most promising aluminum alloy Good corrosion resistance, excellent weld ability, good cold workability, and moderate strength 5052 alloy aluminum strip has high strength, especially high fatigue strength, high plasticity and poor cutting performance, and can be polished.