At a time when the wave of Industry 4.0 and green manufacturing is sweeping the world, the metal material market is undergoing profound changes, and materials with both lightweight and high performance have become the focus of competition in various industries. With its excellent comprehensive performance and wide applicability, aluminum circles stand out from many metal products and have become “star materials” in the fields of construction, automobiles, electronics and even aerospace. Whether it is the gorgeous curtain wall of a high-rise building or the advanced aircraft soaring in the sky, aluminum circles interpret the infinite possibilities of metal materials with a unique attitude.

Next, we will deeply analyze 铝圈 from multiple dimensions such as casting process, performance parameters, and application scenarios to reveal the secret of its popularity and appreciate its unique charm in the process of modern industrial development.

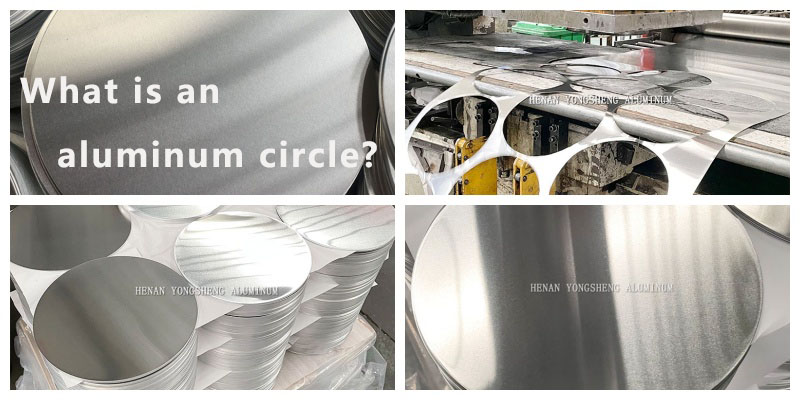

Casting process of aluminum circles

Different casting processes give aluminum circles different characteristics to adapt to different production needs.

Sand casting: low cost, suitable for small batch production, and can manufacture aluminum circles with complex shapes to meet diverse needs.

Metal mold casting: high production efficiency, excellent precision and surface quality of aluminum circle castings, suitable for production scenarios with high quality requirements.

Die casting: suitable for mass production, can create thin-walled, complex-shaped aluminum circles, with high dimensional accuracy and high strength, meeting the needs of large-scale production.

Aluminum circle performance parameters

The excellent performance of aluminum circles comes from their unique chemical composition and physical properties.

Table:Chemical performance parameters

| Chemical elements | Content range | Characteristics |

| 铝质 | ≥98% | Gives the material light weight, good conductivity and corrosion resistance |

| 铜 | 0.1 – 0.5% | Improves strength and hardness |

| 镁 | 0.2 – 0.8% | Enhances material toughness and fatigue resistance |

| 硅 | 0.3 – 1.0% | Improves casting performance |

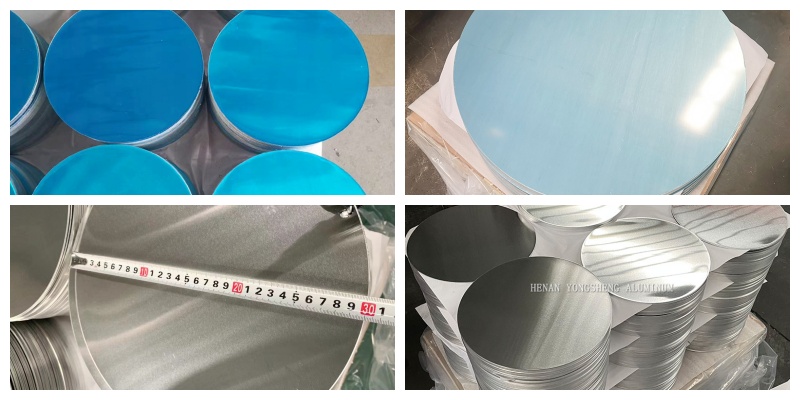

Physical properties: The density of the aluminum circle is about 2.7g/cm³, the melting point is 660℃, and it has good thermal conductivity and ductility, which enables it to function stably under different working conditions.

Application scenarios of aluminum circles

Based on their own performance advantages, aluminum circles can play a key role in many fields.

Building decoration field: It can be made into ceilings, curtain wall decorative panels, etc., with beautiful appearance and corrosion resistance, to improve the quality and service life of buildings.

Automobile manufacturing: used to manufacture engine parts, wheels, etc., effectively reducing the weight of the vehicle body and improving fuel economy.

Electronic and electrical industry: With good conductivity and heat dissipation, it has become a common material for circuit boards and radiators.For example, 1060 铝圆 is commonly used in lampshades, water heater shells, etc.

Aerospace field:

- Aircraft wing manufacturing: parts processed with high-strength aluminum circles can reduce the weight of the aircraft while ensuring the strength of the wing, reduce fuel consumption, and improve flight efficiency.

- Satellite cooling system: using the excellent thermal conductivity of aluminum circles to dissipate the internal heat of the satellite in time to ensure the stable operation of electronic equipment in extreme environments.

- Spacecraft cabin structure: specially treated aluminum circles can resist space radiation and micro-meteorite impacts, providing safety for astronauts and equipment.

Processing and environmental advantages

The strong processing adaptability of aluminum circles makes it possible to meet various personalized needs.

Diversified processing technology: complex shapes and special surface effects can be achieved through secondary processing processes such as stamping, cutting, drilling, and surface treatment.

Personalized customization service: meet the personalized needs of different customers and expand the application boundaries of aluminum circles.

At a time when environmental protection is becoming increasingly important, the sustainable advantages of aluminum circles are particularly prominent.

High recycling rate: Aluminum has an extremely high recycling rate and low energy consumption in the recycling process.

Stable performance: The recycled aluminum circles can still maintain good performance, which is in line with the concept of sustainable development and helps the green development of enterprises.

Include

From casting process to performance parameters, from multiple applications to processing advantages, to environmental protection value, aluminum circles have demonstrated their indispensable position in various industries with their outstanding comprehensive strength. A variety of casting methods lay the foundation for its quality and performance; excellent chemical and physical properties enable it to adapt to different working conditions; its wide application in construction, automobiles, electronics, aerospace and other fields fully demonstrates its value; powerful processing capabilities meet personalized customization needs, and the environmental protection attributes of high recycling rate are in line with the development trend of the times. In the future, with the continuous advancement of technology, aluminum circles are expected to play a greater role in more fields and continue to empower the development of various industries.

常见问题:

Q1: How to choose the aluminum circle specifications suitable for my project?

A: It depends on the key requirements of the application scenario:

Thickness and size: 1.0-3.0mm thin plates are commonly used in architectural decoration, and high-strength thick plates are required in the aerospace field;

Alloy composition: Choose high-purity aluminum for corrosion resistance, and copper/magnesium alloys for strength (refer to the element ratio table in the article);

Process matching: Sand casting for small batch customization, die casting for large batches and high precision. It is recommended to provide specific working parameters and the technical team will recommend a solution.

Q2: Will the aluminum circle deform or crack during processing? How to avoid it?

A: The risk is controllable, and it is necessary to pay attention to:

Material pretreatment: Selecting aluminum circles with strengthening processes such as T6 heat treatment can improve ductility;

Processing parameter optimization: Control feed speed and cooling measures during cutting/stamping;

Structural design: Avoid sharp angles, and arc transitions reduce stress concentration. We provide processing technology guidance services.

Q3: Is there any difference in performance between environmentally friendly recycled aluminum circles and traditional aluminum materials?

A: The performance of recycled aluminum circles is stable and reliable:

The recycling process is mature: the impurity content after remelting and refining is ≤0.1%;

Certification guarantee: It complies with ISO 14021 environmental protection standards and provides material traceability certificates;

Cost advantage: The energy consumption of recycled aluminum is reduced by 95%, and the price is 5-10% lower, which is suitable for procurement projects with strict ESG requirements.