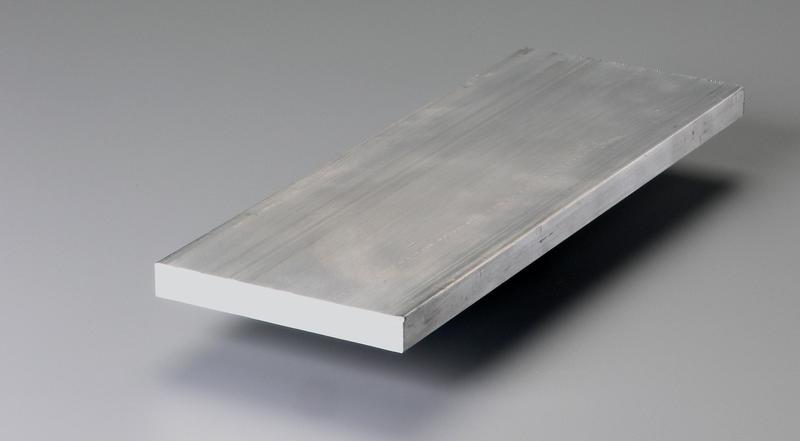

Aluminum alloy 6061 is a widely used material in various industries due to its excellent strength, weldability, and corrosion resistance. The “T6” and “T651” designations refer to different tempering processes applied to this alloy, resulting in variations in mechanical properties and performance. Here’s what each designation means:

1. 6061-T6

T6 temper indicates that the aluminum alloy has been solution heat-treated and artificially aged.

In the T6 temper, the material reaches its highest level of strength and hardness among the temper options for 6061.

It offers excellent mechanical properties and is commonly used in applications where high strength and toughness are required, such as structural components in aerospace, automotive, and marine industries.

2. 6061-T651

651 temper is a subset of T6 temper but with additional stress-relieving processes after solution heat treatment.

After the initial solution heat treatment, the material undergoes stretching or compression to relieve residual stresses, followed by a final aging process.

This temper provides improved flatness and stress corrosion resistance compared to standard T6 temper, making it suitable for applications where dimensional stability is critical, such as precision machining and tooling.

In summary, while both T6 and T651 tempers offer high strength and excellent mechanical properties, the T651 temper provides additional stress relief and improved dimensional stability compared to the standard T6 temper, making it more suitable for certain precision applications. However, the choice between the two tempers ultimately depends on the specific requirements of the application, such as strength, dimensional tolerances, and stress corrosion resistance.