铝质 is a widely used metal, while aluminum coating refers to the process of applying a layer of aluminum onto other materials. Despite the similarity in names, there are significant differences between the two in terms of their nature, properties, and applications. This article will explore in depth the definitions, characteristics, applications, and distinctions between aluminum and aluminum coating, helping readers gain a comprehensive understanding of both.

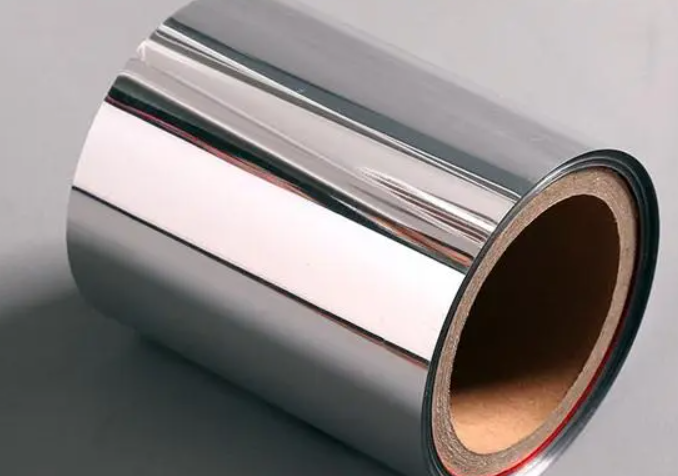

Definition of Aluminum Coating

Aluminum coating involves applying a layer of aluminum to a substrate material using various techniques such as physical vapor deposition, chemical coating, or spraying. This process not only enhances the performance of the base material but also provides unique aesthetic appeal. Common substrates used for aluminum coating include plastics, paper, steel, and aluminum alloys. The thickness of the aluminum coating can be adjusted based on specific needs, typically ranging from a few micrometers to several tens of micrometers.

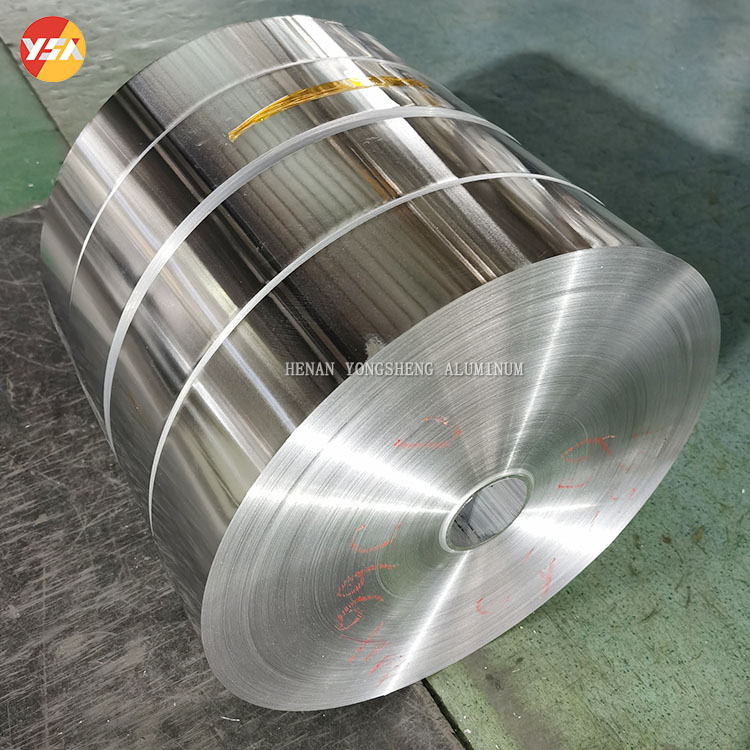

Definition of Aluminum

Aluminum (chemical symbol “Al”) is a lightweight metal with a density that is about one-third that of iron, exhibiting excellent electrical and thermal conductivity. It is found naturally in the form of bauxite, which is refined to produce aluminum oxide. This oxide is then electrochemically processed to create aluminum ingots. The advantages of aluminum include its outstanding corrosion resistance (as aluminum can easily form a protective oxide layer), mechanical strength, and versatility in machining, making it widely applicable in aerospace, construction, transportation, and electronics.

Differences Between Aluminum Coating and Aluminum

– Material Nature: Aluminum is a standalone metallic element, existing as a fundamental material. In contrast, aluminum coating involves the application of aluminum onto other materials, meaning that the coated product cannot be considered an independent material.

– Performance Characteristics:Aluminum displays excellent strength and durability, suitable for high-stress structural applications. In comparison, the performance of coated materials is influenced by the substrate. For example, a thin aluminum coating may not provide the same load-bearing capabilities as pure aluminum, but it can offer some degree of corrosion resistance and aesthetic enhancement.

– Usage Purpose and Fields:Aluminum is utilized in a vast range of applications, from aircraft and vehicles to everyday aluminum cans and foils. Aluminum-coated materials are typically used in products requiring surface protection and treatment, such as food packaging, appliance exteriors, and architectural designs. Their primary purpose is to improve durability and visual appeal.

Applications of Aluminum Coating

– Food Packaging: Aluminum coating films offer excellent barrier properties, preventing moisture and oxygen from permeating, which helps maintain the freshness of food. Hence, they are widely used for packaging snacks, beverages, pharmaceuticals, and other perishable items. This material extends shelf life while preserving the color and flavor of food.

– Building Materials: In construction, aluminum-coated materials are used for roofing and façade applications. They not only provide a modern aesthetic but also enhance the corrosion resistance and weather durability of building materials. Aluminum-coated surfaces endure harsh weather conditions, reducing the need for maintenance.

– Electronics: In the electronics and electrical sectors, aluminum-coated materials serve as protective and shielding layers, preventing electromagnetic interference. Additionally, the aesthetic appeal of aluminum coating helps enhance the market competitiveness of electronic products.

– Automotive Industry: Aluminum coating is widely used in automotive components, providing sufficient strength while being lightweight, which helps improve fuel efficiency and performance.

Sustainability in the Aluminum Industry

In today’s world, with growing environmental awareness, the recyclability of aluminum has become highly significant. The recycling rate of aluminum can reach up to 95%, and aluminum-coated materials can also be environmentally processed through suitable recycling technologies. The future promises innovative aluminum coating techniques and recycling methods that will further reduce resource waste and environmental impact.

Future Trends

Aluminum coating technology continues to evolve with advancements in technology. For example, researchers are exploring new eco-friendly aluminum coatings to replace traditional materials, thereby reducing environmental burdens. Additionally, smart aluminum coating technologies are emerging, utilizing sensors to monitor the thickness and adhesion of the coating to ensure high standards and quality of the final products.

结论

While aluminum and aluminum coating share similarities, they are fundamentally different materials with unique properties and application scenarios. Understanding these distinctions aids in making informed decisions when selecting materials for various purposes. Given the increasing market demand and the focus on environmental sustainability, both aluminum technology and aluminum coating have significant potential for future development, promising innovative material solutions for a variety of applications.