热轧铝圆盘

What is Hot Rolled Aluminum Disc Circle?

Hot rolled aluminum disc circle refers to the process of rolling aluminum coils at high temperatures. During the hot rolling process, the aluminum coil is heated to a higher temperature (usually between 400°C and 550°C) and then plastically deformed through the rolling mill to finally obtain the desired shape and size.

Hot Rolled vs Cold Rolled:

1. Processing method:

Hot rolled aluminum circle: Hot-rolled aluminum circle disc is a process by which aluminum blanks are shaped into the desired shape at high temperatures. In this process, the aluminum billet usually needs to be heated to high temperatures and then processed through rolling machinery.

Cold rolled aluminum disc: Cold rolled aluminum dsic is a process of plastic processing of aluminum billet at room temperature. This process usually does not require preheating but takes place at room temperature, usually via a roller mill.

2. Differences in properties:

Hot rolled aluminum disc circle: Hot-rolled aluminum disc circle usually has lower hardness and higher plasticity. Due to high temperature processing, its grain structure is relatively large and there may be slight grain boundary shrinkage. This makes hot-rolled aluminum disc circle easier to form in some applications, but less hard.

Cold rolled aluminum disc circle: Cold rolled aluminum disc circle usually has higher hardness and smaller grain structure. Because it is processed at room temperature, its grain structure is tighter and therefore has higher hardness and tensile strength.

3. Applicable fields:

Hot rolled aluminum circles: Due to their higher plasticity, hot-rolled aluminum circles are often used in applications that require higher formability, such as aluminum containers, round parts, etc.

Cold rolled aluminum disc: Due to its higher hardness and strength, cold-rolled aluminum round is usually used in applications that require higher strength, such as mechanical parts, structural materials, etc.

Advantages of Hot Rolled Aluminum Disc Circle:

- High plasticity, high formability: hot rolled aluminum discs are particularly suitable for applications requiring deep drawing, drawing or bending.

- Low hardness: Hot rolled aluminum discs generally have low hardness.

- Large size range: Hot rolling aluminum discs can usually be manufactured into larger-sized discs, suitable for the manufacture of large components and parts.

- Low production costs: The hot rolling process is usually fast and suitable for high-volume production, which helps reduce production costs.

- Good deformability: Hot-rolled aluminum discs have good deformability and are suitable for multiple processing and shape adjustments without being prone to cracking or deformation.

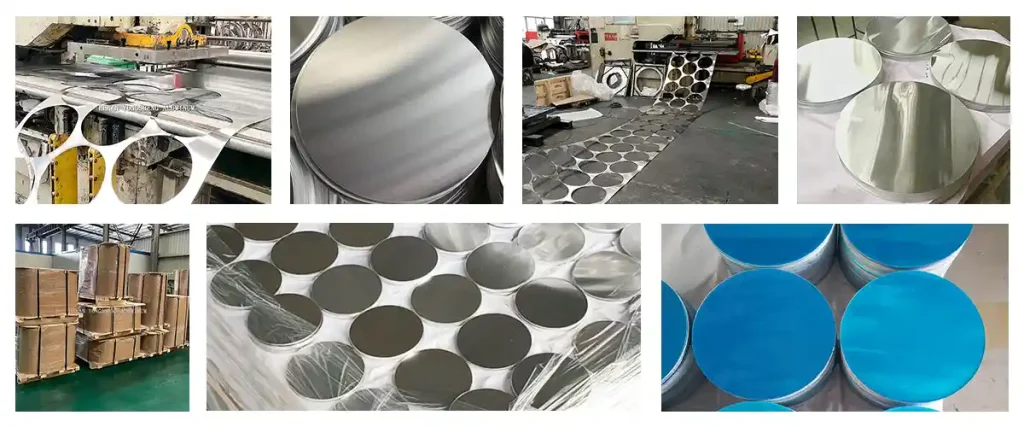

Our Factory:

Product & Packaging Photos

为什么选择我们

永盛铝业是中国领先的铝制品制造商和供应商,拥有 25 年的出口经验。我们出色的产品质量、价格以及始终如一的准时交货为我们赢得了许多长期合作伙伴,并在全球范围内赢得了极高的声誉。我们为 CC 和 DC 铝制品提供一站式产品解决方案。

业务处理流程