薄铝板简介

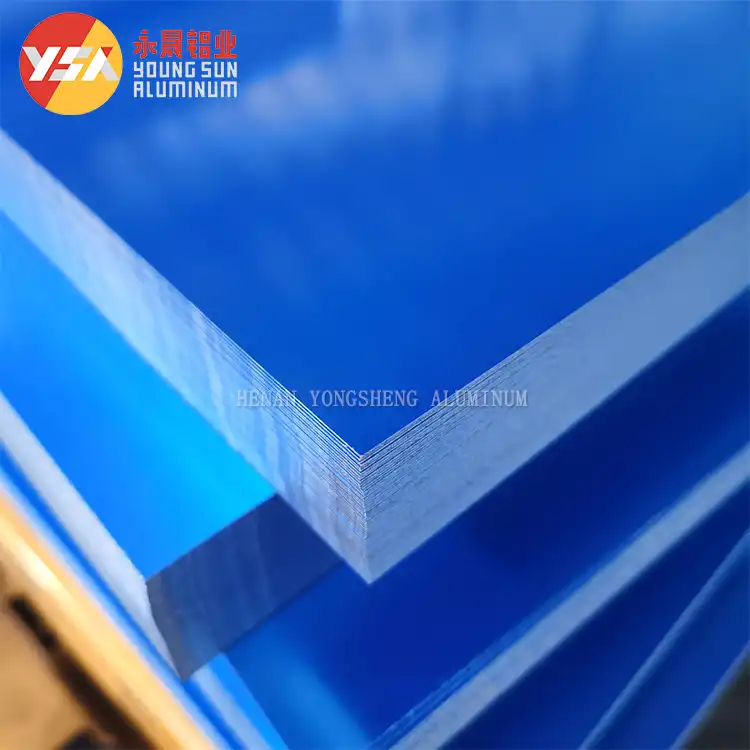

铝薄板是指厚度通常在 0.1 毫米至 6.0 毫米之间的扁平轻质铝片。其特点是成型性好、耐腐蚀、强度重量比高。薄铝板常用于航空航天、汽车、电子、包装和建筑等各行各业。它们具有重量轻、易成型和成本效益高的优点。这些铝板的应用领域主要考虑减轻重量、多功能性和成本效益。

合金 T类型 C妣 T桧 A铝 S他

| 合金类型 | 厚度(毫米) | 密度(克/立方厘米) | 拉伸强度(兆帕) | 屈服强度(兆帕) | 伸长率 (%) |

| 1000 系列 | 0.1 – 6.0 | 2.7 – 2.8 | 70 – 210 | 15 – 100 | 25 – 40 |

| 3000 系列 | 0.1 – 6.0 | 2.7 – 2.8 | 110 – 250 | 55 – 215 | 20 – 30 |

| 5000 系列 | 0.1 – 6.0 | 2.68 – 2.73 | 130 – 320 | 65 – 275 | 10 – 30 |

| 6000 系列 | 0.1 – 6.0 | 2.7 – 2.8 | 170 – 310 | 55 – 275 | 10 – 30 |

| 7000 系列 | 0.1 – 6.0 | 2.7 – 2.8 | 220 – 570 | 140 – 470 | 5 – 25 |

薄铝板的用途是什么?

- 铝罐 薄铝板广泛用于饮料罐的生产。这些铝板被加工成碳酸饮料罐、能量饮料罐、罐装食品罐等。

- 铝箔包装和容器: 薄铝片俗称铝箔,广泛用于包装和储存食品。它们被用于家庭、餐馆、餐饮服务和食品包装行业。

- 电导体: 薄铝板在各种应用中被用作电导体。由于铝具有出色的导电性,它们被用于布线、输电线路、配电盘和母线。

- 散热器: 带有散热片或挤压设计的薄铝板可用作散热器。它们能有效地为计算机处理器、LED 灯和功率电子设备等电子元件散热。

- 屋顶和护墙板: 薄铝板用于建筑业的屋顶和护墙板应用。它们重量轻、耐用、耐腐蚀,适用于住宅和商业建筑。

- 汽车车身面板: 薄铝板用于汽车行业的车身面板,如引擎盖、车门、挡泥板和行李箱盖。铝的轻质特性有助于减轻汽车重量、提高燃油效率和性能。

- 铭牌和标识: 薄铝板通常用于制造铭牌、标签和标牌。它们可以进行雕刻、冲压或印刷,以制作耐用且具有视觉吸引力的标识和品牌元素。

- 反光隔热材料: 具有反射表面的薄铝板可用作隔热材料。它们用于建筑、暖通空调系统和包装,以反射辐射热并提高能效。

- 石版印刷: 薄铝板在印刷业中用作平版印刷板。这些印版经过化学处理,可形成可印刷的表面,用于胶版印刷工艺中的高质量商业印刷。

- 装饰性应用: 薄铝板是室内设计、建筑和艺术项目中常用的装饰材料。它们可用于墙面装饰、天花板瓷砖、装饰面板和艺术装置。

薄铝板的优势

- 轻质结构: 与钢或铜等金属相比,薄铝板的重量要轻很多,因此非常适合那些对减轻重量有严格要求的应用领域。航空航天、汽车和运输等行业都受益于这一优势,因为它能提高燃油效率和整体性能。

- 反射性: 铝对热和光都有很高的反射率。具有反射表面的薄铝板可用于反射器、照明灯具、太阳能电池板和反射隔热材料等应用。它们能有效地引导和分布光和热。

- 成型性 和多功能性: 薄铝板具有出色的可成形性,可轻松成型、弯曲或模压成各种配置。这种多功能性使其适用于需要复杂形状的应用,如汽车车身面板、建筑元素和装饰点缀。

- Aesthetically Pleasing: Aluminum has an inherently attractive appearance, and thin aluminum sheets can be enhanced with different surface treatments, coatings, or anodization to further enhance their visual appeal. They are commonly employed in architectural applications, interior design, and decorative elements.

Thin Aluminum Sheet VS Thick Aluminum Sheet

厚度

Thin Aluminum Sheet: The usual thickness of thin aluminum sheets is between 0.2 and 1.0 mm. Their flexibility and light weight make molding and creating them simple.

Thick Aluminum Sheet: Generally speaking, aluminum sheets that have a thickness of 6.0 mm or more are regarded as thick. They offer strength and durability since they are more substantial and stiff.

Fortitude and Stiffness

Thin Aluminum Sheet: Compared to thicker sheets, thinner sheets are less robust and less rigid. They work well in situations where reducing weight is important but structural strength isn’t always necessary.

Thick Aluminum Sheet: Thick sheets are ideal for applications requiring load-bearing capacity and structural integrity since they have a higher strength and rigidity.

应用

Thin Aluminum Sheet: Thin sheets find applications in industries such as electronics, packaging, automotive interiors, insulation, and decorative applications. They are commonly used for lightweight and flexible purposes.

Thick Aluminum Sheet: Thick sheets are employed in applications that require strength and durability. They are used in aerospace, marine, automotive exteriors, construction, industrial equipment, and heavy-duty structures.

Machinability

Thin Aluminum Sheet: Thin sheets are generally easier to machine due to their lower thickness. They can be cut, drilled, and formed with relative ease using standard machining techniques.

Thick Aluminum Sheet: Thick sheets may require more robust machining equipment and techniques due to their greater thickness. Machining thick sheets may involve more time and effort.

Cost

Thin Aluminum Sheet: Thin sheets are typically less expensive compared to thicker sheets. The lower material cost and reduced weight contribute to their affordability.

Thick Aluminum Sheet: Thick sheets are generally more expensive due to the larger quantity of aluminum required and the additional manufacturing processes involved.

摘要

Thin aluminum sheets are essential components in various industries due to their lightweight design, versatility, and favorable properties. They find applications in aerospace, automotive, electronics, construction, and packaging, offering advantages such as lightweight construction, corrosion resistance, thermal and electrical conductivity, formability, and recyclability. While thin sheets excel in weight reduction and flexibility, thicker aluminum sheets may provide higher strength and load-bearing capabilities. The choice between thin and thick aluminum sheets depends on specific application requirements and performance needs. Overall, thin aluminium sheets play a vital role in driving innovation, efficiency, and sustainability across industries.

常见问题

How thin can you get aluminum sheets?

Aluminum sheets can be manufactured to extremely thin dimensions, reaching thicknesses as low as 0.005 mm (5 microns) in specialized processes. However, such ultra-thin aluminum sheets are not commonly available and require specialized manufacturing techniques.

How strong is 3mm aluminum plate?

The strength of a 3mm aluminum plate can vary depending on the specific alloy and temper. Generally, aluminum has a high strength-to-weight ratio, and a 3mm aluminum plate can provide sufficient strength for various applications. The exact strength characteristics depend on factors such as the alloy composition, heat treatment, and the intended use of the plate.

What is the thinnest sheet metal you can buy?

The thinnest sheet metal available commercially can be as thin as 0.001 inches (0.0254 mm) or even thinner. These extremely thin sheet metals are typically used in specialized applications, such as electronics, where precision and flexibility are crucial.

What is the cheapest type of aluminum sheet?

The cost of aluminum sheets can vary depending on factors such as alloy composition, thickness, and market conditions. Generally, pure aluminum sheets (1000 series) tend to be the least expensive due to their lower alloying elements. However, prices can fluctuate, and other factors such as sheet size and quantity also affect the overall cost.

What is lightweight aluminum?

Lightweight aluminum refers to aluminum alloys that have been specifically designed to have reduced weight while keeping strength and other desirable characteristics. These alloys mainly have a lower density compared to other metals, making them attractive for uses that prioritize weight reduction, such as aerospace, automotive, and transportation industries. Lightweight aluminum alloys can help enhance fuel efficiency, increase payload capacity, and enhance comprehensive performance.