Алюминиевый лист 3003 H14

Модель сплава: 3003 H14 Aluminum

Темпер: O, H12, H14, H24, H16, H26, H18

Толщина: 0,10 мм - 350 мм

Поставка: Готовые запасы: 7-10 дней, будущие товары: 15-30 дней

MOQ: 3 тонны

Упаковка: Морской деревянный поддон, деревянный ящик, ящик из алюминиевых пластин.

Что такое 3003 H14 Aluminum Sheet?

The alloy 3003 H14 aluminum sheet is a member of the 3000 class of alloys containing aluminum and manganese. Its primary constituents are 1.2% manganese and 98.6% aluminum. The 3003 H14 aluminum sheet has undergone strain hardening and partial annealing, yielding a material with moderate strength and acceptable formability, as indicated by the “H14” temper designation. It is frequently utilized in applications that need for a compromise between strength and formability, such as general sheet metal production, chemical equipment, and kitchen utensils.

Specifications of 3003 H14 Алюминиевый лист

| Aluminum Grade | 3003 |

| Temper | O, H12, H14, H16, H18, H22, H24, H26 |

| Название | 3000 Series aluminum sheet, aluminum alloy sheet, Anti-rust aluminum alloy sheet |

| Form | Aluminum Plain sheet, 3003 Aluminum coil, Aluminum 3003-h14 perforated sheet |

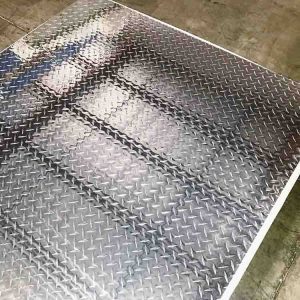

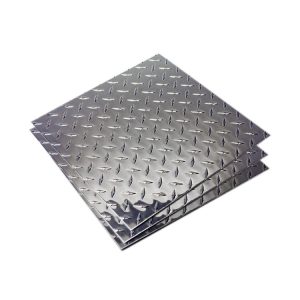

| Обработка поверхности | Aluminum bare sheet, mill finish, mirror finish, aluminum tread plate |

| Толщина | 0,10 мм-350 мм |

| Ширина | 100 мм-2600 мм |

| Длина | Длина любая, в зависимости от транспортировки, обычно не более 12 м. |

| Protection | Aluminum sheet with PVC films or paper-interleaved |

Свойства из 3003 H14 Aлюминий Sheet

Химический состав

| Сплав | Si | Fe | Cu | Mn | Mg | Zn | Al |

| 3003 | 0.6 | 0.7 | 0.05~0.20 | 1.0~ 1.5 | — | 0.1 | остаток |

Механические свойства

| Сплав | Прочность на разрыв | Stretch rate(%) | Dimension Control | Поверхность |

| Aluminum sheet 3003-H14 | Standard Value >195 | Standard Value ≥1 | Qualified | Qualified |

Physical Pсвойства

| Недвижимость | Значение |

| Плотность | 2,73 г/см³ |

| Температура плавления | 655°C (1211°F) |

| Теплопроводность | 190 W/m·K |

| Электропроводность | 40% IACS (International Annealed Copper Standard) |

| Модуль упругости | 69 ГПа (10,000 кси) |

| Коэффициент теплового расширения | 23.6 μm/m·°C (12.5 μin/in·°F) |

| Твердость (Бринелль) | 45 HB |

3003 H14 Aluminum Sheet Features

| Feature | Описание |

| Formability | Excellent formability, can be easily shaped, bent, or formed without cracking |

| Коррозионная стойкость | Good resistance to corrosion, suitable for humid or marine environments |

| Свариваемость | Good weldability, can be easily joined using various welding techniques |

| Легкий | Low density, lightweight material for weight reduction applications |

| Универсальность | Widely used in automotive, construction, packaging, and HVAC industries |

Алюминиевый лист 3003 H14 Приложения

3003 H14 aluminum sheet finds application in various industries and sectors due to its desirable properties. Some common applications include:

- Roofing and Siding: The corrosion resistance and formability of 3003 H14 make it suitable for roofing and siding uses in residential, commercial, and industrial buildings.

- HVAC (Heating, Ventilation, and Air Conditioning): This alloy is used for manufacturing ductwork, heat exchangers, and other components in HVAC systems owing to its lightweight nature and good thermal conductivity.

- Food and Beverage Packaging: 3003 H14 aluminum sheet is generally used in the production of food and beverage cans, containers, and lids owing to its non-toxicity, moisture resistance, and formability.

- Chemical Equipment: The corrosion resistance of 3003 H14 aluminum sheet makes it suitable for manufacturing chemical equipment such as storage tanks, pipes, and fittings that come into contact with various chemicals.

- Heat Sinks: The thermal conductivity of 3003 H14 makes it suitable for heat sink applications where efficient heat dissipation is needed, such as in electronic devices and LED lighting.

- General Sheet Metal Fabrication: This alloy is widely used in various sheet metal fabrication applications, including automotive parts, signage, panels, and decorative trim, due to its formability and corrosion resistance.

- Cooking Utensils: 3003 H14 is often used in the production of cooking utensils such as pots, pans, and baking sheets owing to its non-reactivity with food, excellent heat transfer, and ease of fabrication.

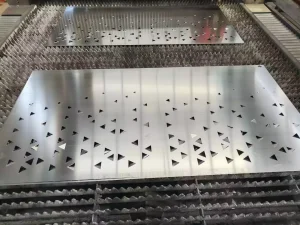

3003 H14 Perforated Aluminum Sheet

H14 perforated aluminum sheet refers to a specific type of 3003 aluminum alloy sheet that has been processed to have perforations or holes in its surface. The “H14” temper designation indicates that the sheet has undergone strain hardening and partial annealing, providing moderate strength and good formability. Perforated aluminum sheets are commonly used in applications where airflow, visibility, or filtration is desired, such as in architectural, decorative, or industrial applications. The perforations can be in various shapes (round, square, slotted, etc.) and sizes, allowing for customization based on specific project requirements.

3003 H14 Алюминиевый лист vs 5052 H32 Алюминиевый лист

| Недвижимость | 3003-H14 Aluminum Sheet | 5052-H32 Aluminum Sheet |

| Alloy Composition | алюминиевый сплав 3003 | 5052 aluminum alloy |

| Temper | H14 | H32 |

| Formability | Excellent formability, easily shaped and formed | Good formability, easily shaped and formed |

| Прочность | Moderate strength | Moderate to high strength |

| Коррозионная стойкость | Good resistance to corrosion | Excellent resistance to corrosion |

| Свариваемость | Good weldability | Good weldability |

| Типовые применения | Roofing, siding, general sheet metal fabrication | Marine applications, structural components, panels |

| Surface Finish | Mill finish, can be further treated for aesthetics | Mill finish, can be further treated for aesthetics |

| Плотность | 2,73 г/см³ | 2,68 г/см³ |

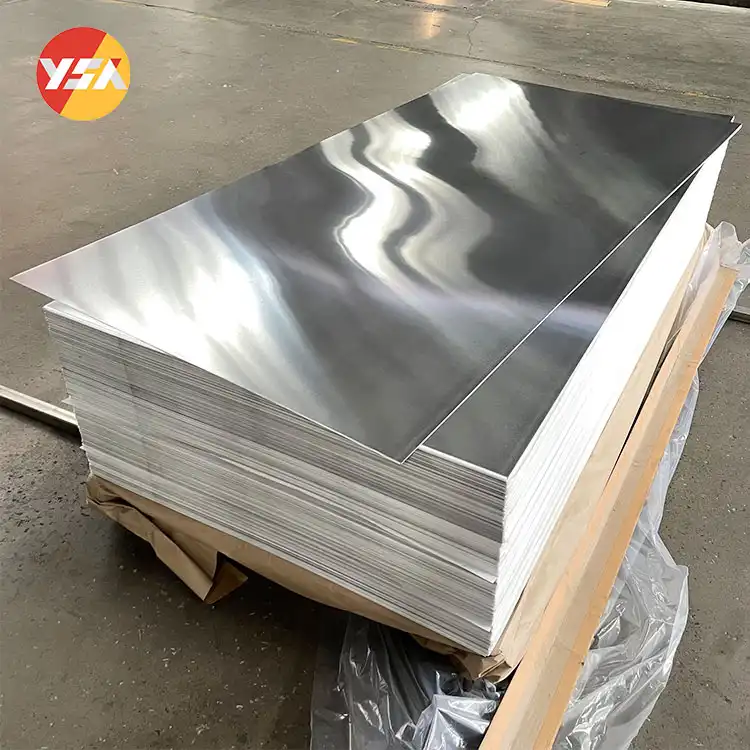

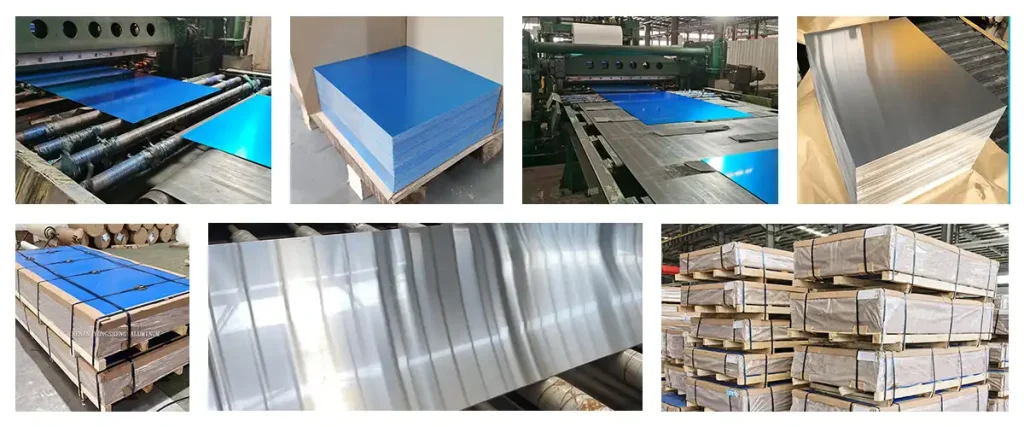

Фотографии продукции и упаковки

Почему мы выбираем нас

Компания Yongsheng Aluminum является ведущим производителем и поставщиком алюминиевой продукции в Китае с 25-летним опытом экспорта. Высокое качество продукции, цены и своевременная поставка позволили нам завоевать репутацию долгосрочного партнера во всем мире. Мы предлагаем комплексные решения для алюминиевых изделий CC и DC.

Процессы управления бизнесом