3003 H14 Aluminum Sheet

Alloy model: 3003 H14 Aluminum

Temper: O, H12, H14, H24, H16, H26, H18

Thickness: 0.10mm-350mm

Delivery: Ready stock: 7-10 days, future goods: 15-30 days

MOQ: 3 tons

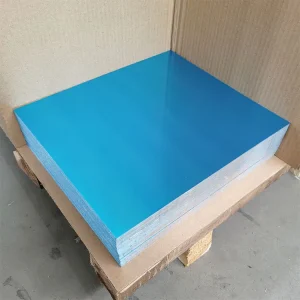

Packaging: Seaworthy wooden pallet, wooden case, aluminum plate case.

What is 3003 H14 Aluminum Sheet?

The alloy 3003 H14 aluminum sheet is a member of the 3000 class of alloys containing aluminum and manganese. Its primary constituents are 1.2% manganese and 98.6% aluminum. The 3003 H14 aluminum sheet has undergone strain hardening and partial annealing, yielding a material with moderate strength and acceptable formability, as indicated by the “H14” temper designation. It is frequently utilized in applications that need for a compromise between strength and formability, such as general sheet metal production, chemical equipment, and kitchen utensils.

Specifications of 3003 H14 Aluminum Sheet

| Aluminum Grade | 3003 |

| Temper | O, H12, H14, H16, H18, H22, H24, H26 |

| Name | 3000 Series aluminum sheet, aluminum alloy sheet, Anti-rust aluminum alloy sheet |

| Form | Aluminum Plain sheet, 3003 Aluminum coil, Aluminum 3003-h14 perforated sheet |

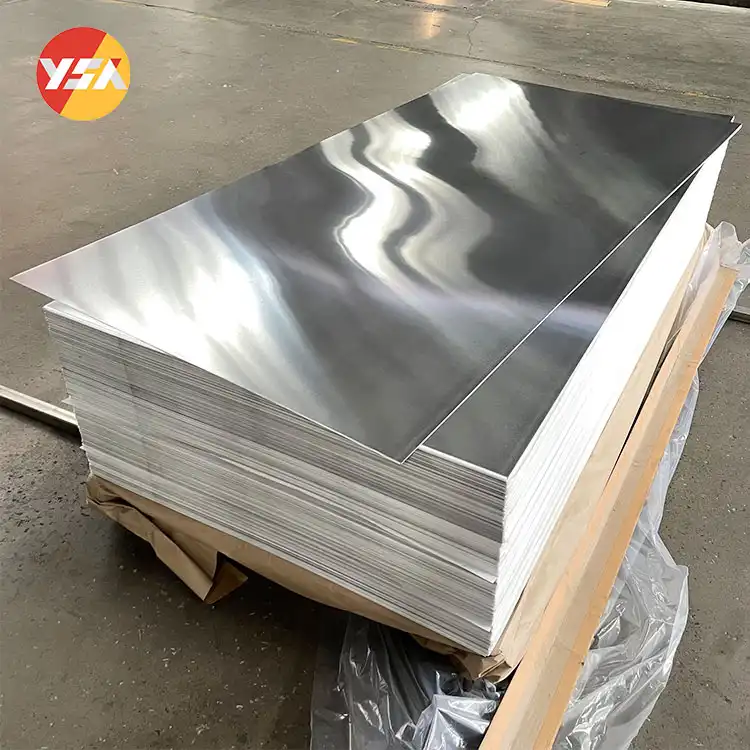

| Surface treatment | Aluminum bare sheet, mill finish, mirror finish, aluminum tread plate |

| Thickness | 0.10 mm-350 mm |

| Width | 100 mm-2600 mm |

| Length | Any length, according to the transportation, usually less than 12m. |

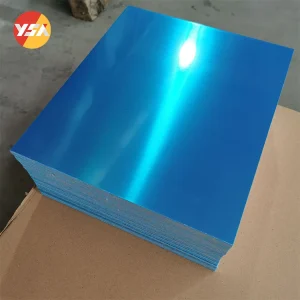

| Protection | Aluminum sheet with PVC films or paper-interleaved |

Properties of 3003 H14 Aluminum Sheet

Chemistry Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Al |

| 3003 | 0.6 | 0.7 | 0.05~0.20 | 1.0~ 1.5 | — | 0.1 | remainder |

Mechanical Properties

| Alloy | Tensile strength | Stretch rate(%) | Dimension Control | Surface |

| Aluminum sheet 3003-H14 | Standard Value >195 | Standard Value ≥1 | Qualified | Qualified |

Physical Properties

| Property | Value |

| Density | 2.73 g/cm³ |

| Melting Point | 655°C (1211°F) |

| Thermal Conductivity | 190 W/m·K |

| Electrical Conductivity | 40% IACS (International Annealed Copper Standard) |

| Modulus of Elasticity | 69 GPa (10,000 ksi) |

| Coefficient of Thermal Expansion | 23.6 μm/m·°C (12.5 μin/in·°F) |

| Hardness (Brinell) | 45 HB |

3003 H14 Aluminum Sheet Features

| Feature | Description |

| Formability | Excellent formability, can be easily shaped, bent, or formed without cracking |

| Corrosion Resistance | Good resistance to corrosion, suitable for humid or marine environments |

| Weldability | Good weldability, can be easily joined using various welding techniques |

| Lightweight | Low density, lightweight material for weight reduction applications |

| Versatility | Widely used in automotive, construction, packaging, and HVAC industries |

3003 H14 Aluminum Sheet Applications

3003 H14 aluminum sheet finds application in various industries and sectors due to its desirable properties. Some common applications include:

- Roofing and Siding: The corrosion resistance and formability of 3003 H14 make it suitable for roofing and siding uses in residential, commercial, and industrial buildings.

- HVAC (Heating, Ventilation, and Air Conditioning): This alloy is used for manufacturing ductwork, heat exchangers, and other components in HVAC systems owing to its lightweight nature and good thermal conductivity.

- Food and Beverage Packaging: 3003 H14 aluminum sheet is generally used in the production of food and beverage cans, containers, and lids owing to its non-toxicity, moisture resistance, and formability.

- Chemical Equipment: The corrosion resistance of 3003 H14 aluminum sheet makes it suitable for manufacturing chemical equipment such as storage tanks, pipes, and fittings that come into contact with various chemicals.

- Heat Sinks: The thermal conductivity of 3003 H14 makes it suitable for heat sink applications where efficient heat dissipation is needed, such as in electronic devices and LED lighting.

- General Sheet Metal Fabrication: This alloy is widely used in various sheet metal fabrication applications, including automotive parts, signage, panels, and decorative trim, due to its formability and corrosion resistance.

- Cooking Utensils: 3003 H14 is often used in the production of cooking utensils such as pots, pans, and baking sheets owing to its non-reactivity with food, excellent heat transfer, and ease of fabrication.

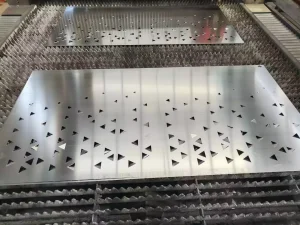

3003 H14 Perforated Aluminum Sheet

H14 perforated aluminum sheet refers to a specific type of 3003 aluminum alloy sheet that has been processed to have perforations or holes in its surface. The “H14” temper designation indicates that the sheet has undergone strain hardening and partial annealing, providing moderate strength and good formability. Perforated aluminum sheets are commonly used in applications where airflow, visibility, or filtration is desired, such as in architectural, decorative, or industrial applications. The perforations can be in various shapes (round, square, slotted, etc.) and sizes, allowing for customization based on specific project requirements.

3003 H14 Aluminum Sheet vs 5052 H32 Aluminum Sheet

| Property | 3003-H14 Aluminum Sheet | 5052-H32 Aluminum Sheet |

| Alloy Composition | 3003 aluminum alloy | 5052 aluminum alloy |

| Temper | H14 | H32 |

| Formability | Excellent formability, easily shaped and formed | Good formability, easily shaped and formed |

| Strength | Moderate strength | Moderate to high strength |

| Corrosion Resistance | Good resistance to corrosion | Excellent resistance to corrosion |

| Weldability | Good weldability | Good weldability |

| Typical Applications | Roofing, siding, general sheet metal fabrication | Marine applications, structural components, panels |

| Surface Finish | Mill finish, can be further treated for aesthetics | Mill finish, can be further treated for aesthetics |

| Density | 2.73 g/cm³ | 2.68 g/cm³ |

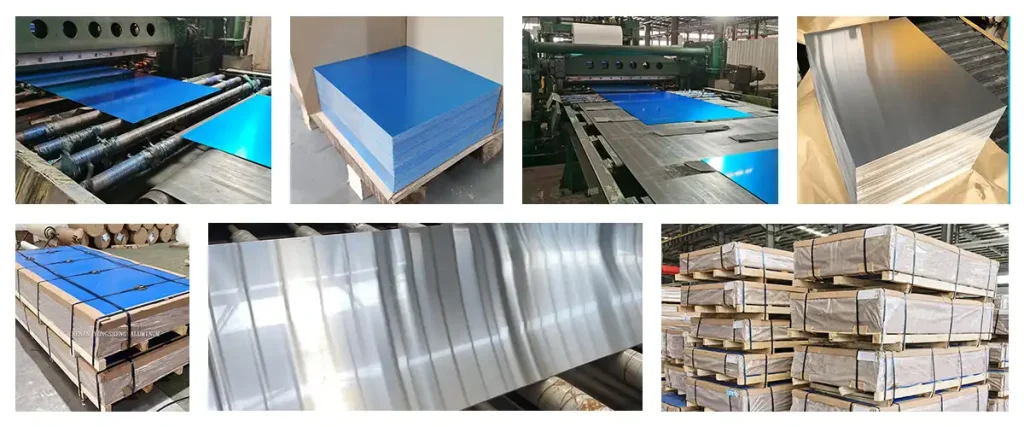

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Business Handling Processes