What Is 1060 Aluminum Coil?

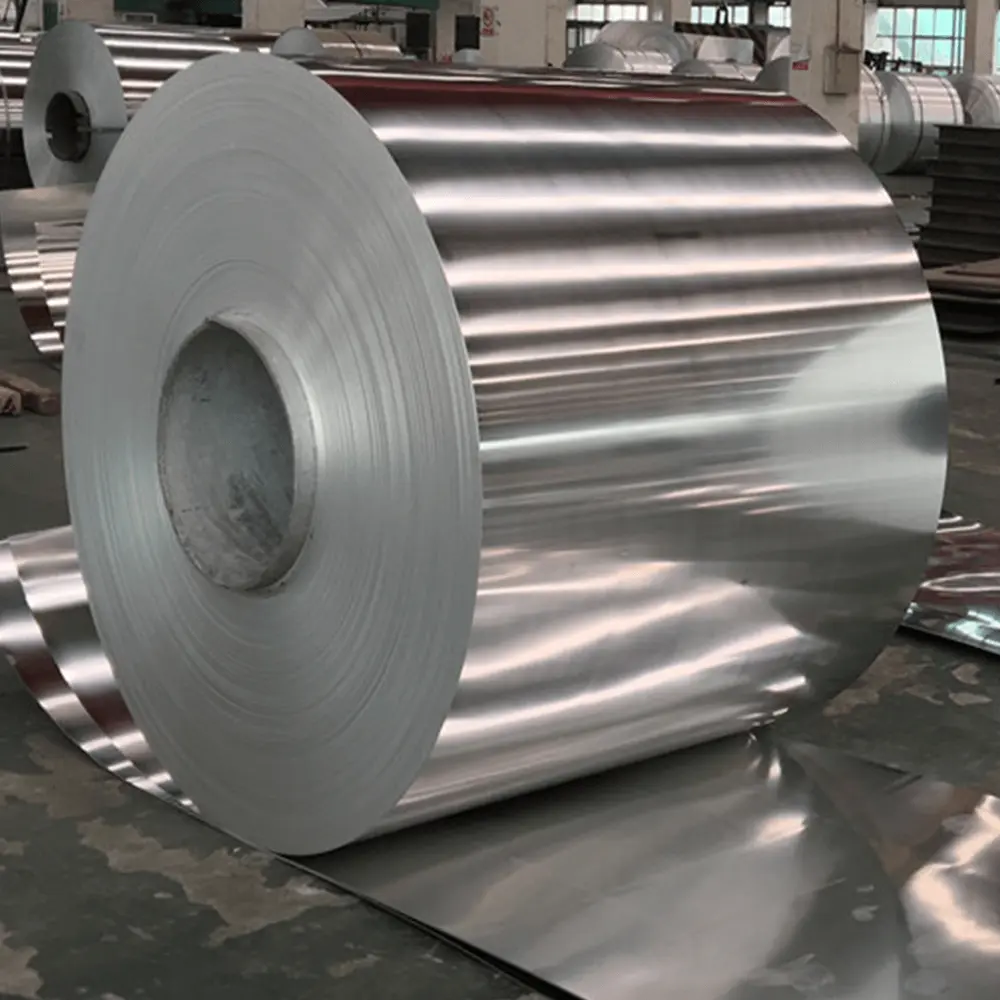

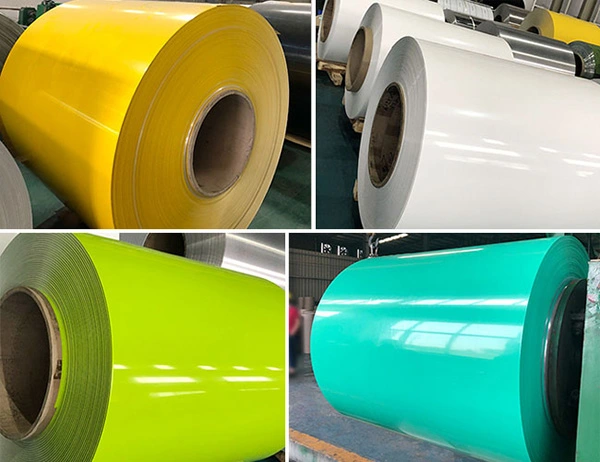

1060 aluminum coil is a kind of 1000 series aluminium alloy coil, the main component is aluminium, containing a small amount of other elements such as iron, silicon, copper, etc. The aluminium content of 1060 aluminium coil is more than 99.6%, which is a kind of high purity aluminium alloy. It is usually produced in the O state, with a fully annealed soft state, and is easy to process. In addition, 1060 aluminium coil can be produced in a variety of surface finishes including mill finish, brushed finish and embossed finish. Of all the finishes, mill finish is the most common surface finish with a smooth, glossy surface that requires no additional treatment; brushed finish is a surface finish with a matte appearance that is created by brushing the surface with a wire brush; and embossed finish is produced by embossing a pattern on the surface to create a textured surface. 1060 aluminium coils can also be coated with a variety of materials, such as PVDF, PE and Epoxy. The coatings protect the aluminium from the elements and can be applied to the aluminium.

The main applications of 1060 aluminum coil include construction, transportation, electronics and household appliances. This article will focus on the characteristics and advantages of 1060 aluminum coils.

Characteristics Of 1060 Aluminum Coil:

Mechanical Properties Of 1060 Aluminum Coil:

The mechanical properties of 1060 aluminum coil are high formability and good corrosion resistance. In terms of tensile strength, 1060 aluminum coils typically range from 55-90 MPa (8,000-13,000 psi), depending on the temper and thickness of the coil. 1060 aluminum coils typically have a yield strength of around 35-70 MPa (5,000-10,000 psi). Elongation at break is typically between 20-40%. These values may vary according to the specific state and processing conditions of the coil and the above data are for reference only.

Physical Properties Of 1060 Aluminum Coil:

1060 aluminum coil has a density of about 2.7 grams per cubic centimeter (g/cm3) and a melting point of about 660 degrees Celsius (1220 degrees Fahrenheit). In addition, the 1060 aluminum coil exhibits excellent electrical conductivity, the electrical conductivity is about 61% of the International Annealed Copper Standard (IACS), and the related thermal conductivity is about 237 watts per meter Kelvin (W/m K), which is a good thermal conductivity. conductor. In contrast, the hardness of 1060 aluminum coil is lower than that of 5052 aluminum coil, because it is a soft aluminum alloy, while 5052 is an alloy aluminum plate. Its tensile strength is between 210-230, which is about 10% higher than that of 1060 aluminum coil.

Chemical Properties Of 1060 Aluminum Coil:

1060 aluminium coil is mainly composed of aluminium (99.6%) and other alloying elements such as iron (0.35%) and silicon (0.25%). 1060 aluminum offers good corrosion resistance in a variety of settings because to its high aluminium content, except in highly acidic or alkaline circumstances. Furthermore, the alloy has great workability and a variety of surface treatments, including mill finish, brushed finish, and anodised finish, allowing it to easily satisfy the different functional requirements of clients.

Advantages Of 1060 Aluminum Coil:

1060 aluminum coil offers several advantages that make it ideal for a variety of applications.

- Aluminum 1060 coil is corrosion resistant and suitable for outdoor applications exposed to harsh weather conditions. Although not as good as other alloy grades such as 3003 aluminum coils and 6061 aluminum coils, they are more attractive to those projects that value cost.

- 1060 aluminum has good electrical conductivity. This characteristic makes it useful in electrical and electronic applications such as power transmission lines, transformer windings and heat sinks. The high conductivity of 1060 aluminum coils ensures efficient energy transfer and helps dissipate heat, making them valuable in the electronics industry.

- 1060 aluminum coils exhibit excellent thermal conductivity. This characteristic makes them ideal for applications requiring efficient heat transfer, such as heat exchangers, radiators, and air conditioning systems. The excellent thermal conductivity of the 1060 aluminum coil allows for efficient heat dissipation, helping to improve the overall performance and energy efficiency of these systems.

- Aluminum coils 1060 are light in weight and have a high strength-to-weight ratio. This combination of properties gives them an advantage in industries where weight reduction is critical, such as aerospace and automotive manufacturing. The lightweight properties of 1060 aluminum coils help improve fuel efficiency and enhance the overall performance of vehicles and aircraft.

- Aluminum 1060 can be easily formed, fabricated and welded, allowing flexibility in the design and manufacturing process. This advantage makes them suitable for a variety of applications including automotive body panels, signage and architectural structures.

Yongsheng 1060 Aluminum Coil:

Yongsheng Aluminium has 5 semi-continuous casting production lines, 12 continuous casting and rolling production lines, 35 other large-scale processing equipment, and an annual production capacity of 300,000 tons. The strong production capacity ensures fast delivery and excellent cost performance. Yongsheng aluminium coils are exported to more than 30 countries such as Singapore, Germany, Holland, Japan, UK, Australia, etc. We provide customers with aluminium coils from all states. The thickness of 1060 aluminium coil can be up to 0.006mm-8.0mm, the width range is 3mm-2600mm, and we provide a wide range of surface treatments such as polished, coated, anodized, mirror, embossed, checkered and so on. More Importantly, 1060 aluminium coils offer huge advantages over other premium alloy aluminium sheets, with cleaner surfaces, precise geometries and higher gloss.