Introduction

When it comes to sourcing aluminum sheets for your business, choosing the right supplier is crucial. The quality of the materials, reliability of deliveries, and overall customer support can significantly impact your operations. To help you navigate the process, this article presents a comprehensive guide on selecting an aluminum sheet supplier. We will explore essential tips and guidelines to consider, enabling you to make an informed decision and forge a successful partnership.

Assessing Quality and Standards

Understanding different aluminum sheet grades

Aluminum sheets come in various grades, each suited for specific applications. Familiarize yourself with industry standards such as the Aluminum Association’s alloy designations to ensure the supplier offers the appropriate grade for your needs.

Checking supplier certifications and compliance

Look for suppliers who hold relevant certifications, such as ISO 9001 or ISO 14001. These certifications indicate their commitment to quality management and environmental stewardship.

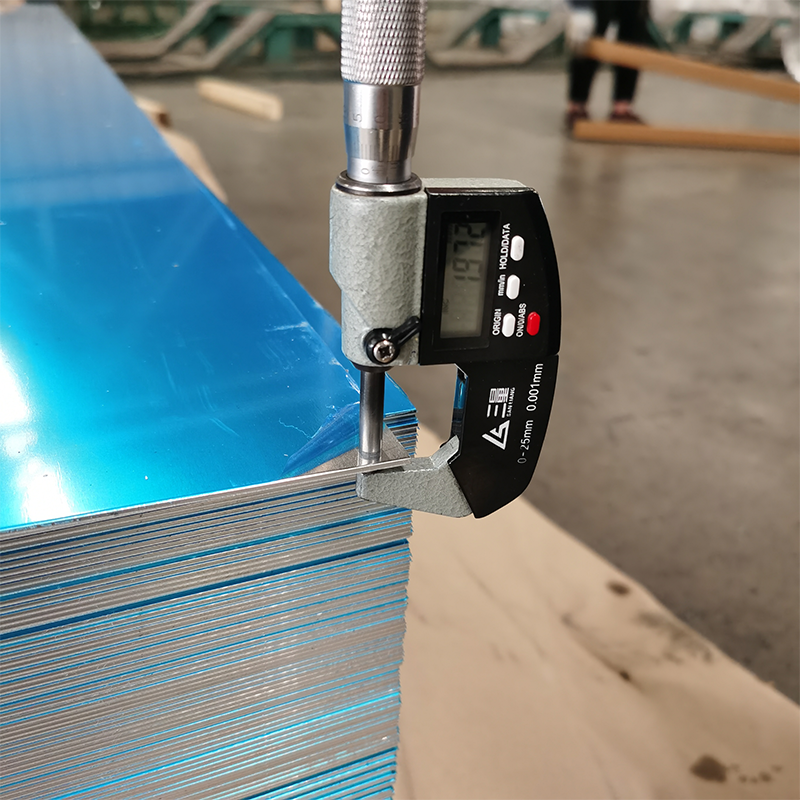

Evaluating the supplier’s quality control processes

Inquire about the aluminum sheet supplier’s quality control procedures, including testing methods and certifications. A reputable supplier should have rigorous quality checks in place to ensure consistent product performance.

Range and Variety of Products

Exploring the supplier’s product catalog

A comprehensive product catalog demonstrates the aluminum plate supplier’s commitment to meeting diverse customer needs. Look for a wide range of aluminum sheet sizes, thicknesses, and configurations.

Assessing the availability of different alloy types

Depending on your industry and specific requirements, you may need different aluminum alloys. Ensure the supplier offers a variety of alloys with varying properties, such as strength, corrosion resistance, and formability.

Considering the supplier’s ability to meet specific requirements

If you have unique specifications or customizations, inquire whether the supplier can accommodate special requests. Flexibility in manufacturing capabilities is crucial for tailored solutions.

Pricing and Cost Considerations

Understanding the factors influencing aluminum sheet prices

Gain insight into the key factors affecting pricing, such as market trends, alloy type, quantity, and processing complexity. Understanding these factors will help you assess pricing structures effectively.

Comparing pricing structures among suppliers

Obtain quotes from multiple aluminum sheet suppliers and compare their pricing structures. Look for transparency in pricing breakdowns to understand the cost components and identify any hidden charges.

Assessing the supplier’s transparency in pricing

A reliable aluminum plate supplier should be open and transparent about their pricing policies. Seek clarity on payment terms, potential discounts for bulk orders, and any other cost-related considerations.

Reliability and Reputation

Researching the supplier’s reputation in the industry

Look for testimonials, reviews, and references to gauge the aluminum sheet supplier’s reputation. Online platforms, industry forums, and referrals from trusted contacts can provide valuable insights.

Evaluating their track record and customer reviews

Assess the supplier’s track record in terms of timely deliveries, order accuracy, and customer satisfaction. Check for reviews and feedback from previous customers to get an idea of their performance.

Considering the supplier’s financial stability and longevity

A financially stable supplier is more likely to ensure consistent product availability and support. Research their financial health and longevity in the industry to assess their stability.

Customer Support and Services

Assessing the supplier’s responsiveness to inquiries

Prompt and attentive customer support is essential for a smooth partnership. Evaluate how quickly and effectively the supplier responds to inquiries or requests for technical information.

Evaluating their technical support capabilities

Inquire about the aluminum sheet supplier’s technical expertise and support services. A knowledgeable team that can provide guidance on material selection, design considerations, or troubleshooting is invaluable.

Considering additional value-added services offered

Some aluminum plate suppliers may offer additional services such as cutting, fabrication, or surface treatment. Assess whether these services align with your requirements and can add value to your operations.

Supply Chain Management

Understanding the supplier’s inventory management

Ask about the supplier’s inventory management system to ensure they can meet your demand consistently. A well-managed inventory reduces the risk of stockouts and delays.

Assessing their ability to meet delivery deadlines

Reliability in meeting delivery deadlines is crucial for maintaining your production schedule. Inquire about the supplier’s track record in on-time deliveries and their contingency plans for potential disruptions.

Evaluating their logistics and shipping capabilities

Consider the aluminum sheet supplier’s logistics capabilities, especially if you operate in different regions or require international shipments. Assess their ability to handle transportation, customs procedures, and any associated documentation.

Environmental and Sustainability Practices

Researching the supplier’s commitment to sustainability

As environmental consciousness grows, partnering with a supplier aligned with your sustainability goals can be advantageous. Inquire about their initiatives to reduce energy consumption, minimize waste, and promote recycling.

Evaluating their recycling and waste management efforts

Sustainable practices extend beyond production. Assess the supplier’s waste management strategies, recycling programs, and their commitment to minimizing the environmental impact of their operations.

Considering their use of renewable energy sources

Renewable energy adoption showcases a supplier’s commitment to sustainable operations. Inquire about their use of solar or wind energy, as it can contribute to reducing carbon emissions.

Geographic Promixity and Accessibility

Assessing the supplier’s location in relation to your business

Proximity plays a role in logistics efficiency and potential cost savings. A supplier located closer to your facility may offer shorter lead times, reduced transportation costs, and easier collaboration.

Considering the ease of transportation and logistics

Evaluate the transportation infrastructure and connectivity around the supplier’s location. Easy access to highways, ports, or airports can streamline shipping and lower overall logistical complexities.

Evaluating potential language and cultural barriers

If dealing with an aluminum sheet supplier from a different country or region, consider any language or cultural differences that may impact communication or understanding. Clear communication is essential for a successful partnership.

Long-term Partnership Potential

Assessing the supplier’s willingness to collaborate and innovate

Look for a supplier who is open to collaboration, eager to understand your specific needs, and willing to explore innovative solutions. A proactive approach to partnership enhances long-term success.

Evaluating their ability to handle future growth

Consider your business’s growth plans and assess whether the supplier can accommodate your increasing demands in the long run. Scalability is crucial to ensure a sustainable partnership.

Considering the potential for a mutually beneficial partnership

Seek aluminum sheet suppliers who view the relationship as a partnership rather than a transaction. Look for shared values, a collaborative mindset, and a commitment to supporting your business growth.

Negotiation and Contract Terms

Understanding negotiation strategies for favorable terms

Familiarize yourself with negotiation tactics to secure favorable pricing, terms, and conditions. Research market trends, industry benchmarks, and common contractual clauses to negotiate effectively.

Assessing the supplier’s flexibility in contract agreements

Flexibility in contract terms is crucial to accommodate any future changes or unforeseen circumstances. Evaluate the supplier’s willingness to negotiate terms and make amendments if necessary.

Evaluating the clarity of terms and conditions

Ensure that all terms and conditions are clearly outlined in the contract. Pay attention to details such as order cancellation policies, warranty periods, liability clauses, and any other relevant contractual provisions.

Backup and Redundancy Plans

Assessing the supplier’s contingency plans for disruptions

Inquire about the aluminum sheet supplier’s strategies for handling disruptions such as equipment failure, raw material shortages, or natural disasters. A robust backup plan demonstrates their commitment to reliability.

Evaluating their ability to handle unexpected demand spikes

Consider scenarios where demand unexpectedly increases, and assess the supplier’s capacity to scale up production to meet your requirements. A responsive supplier can prevent supply shortages during such spikes.

Considering their partnerships with alternative suppliers

Partnerships with alternative suppliers indicate the supplier’s preparedness to ensure continuity in the face of unforeseen circumstances. Inquire about their network and collaborations to maintain a steady supply.

Industry Involvement and Engagement

Researching the supplier’s participation in industry associations

Active involvement in industry associations showcases a supplier’s commitment to staying updated with industry trends, advancements, and best practices. Such engagement demonstrates their dedication to excellence.

Assessing their engagement in research and development

Inquire about the supplier’s investment in research and development (R&D) activities. A supplier with a focus on R&D is likely to offer innovative products and solutions that align with emerging industry needs.

Considering their commitment to staying updated with industry trends

The aluminum industry is constantly evolving. Look for aluminum sheet suppliers who stay informed about market trends, technological advancements, and changing regulations. Their awareness can contribute to better product offerings.

Case Studies and References

Seeking references and testimonials from existing customers

Request references from the supplier to connect with their current customers. Hearing about their experiences and satisfaction levels firsthand can provide valuable insights into the supplier’s capabilities.

Reviewing case studies of successful partnerships

Case studies highlight real-world scenarios and successful collaborations. Look for case studies that resemble your industry or specific requirements to gain a better understanding of the supplier’s expertise.

Assessing the supplier’s ability to provide references upon request

A reputable aluminum sheet supplier should have no hesitation in providing references or testimonials. Their willingness to share customer experiences demonstrates confidence in their product quality and service.

Conclusion

Selecting the right aluminum sheet supplier is a critical decision that can impact the success of your business. By following the tips and guidelines outlined in this article, you can navigate the selection process with confidence. Assessing quality and standards, considering product range, evaluating pricing and reliability, prioritizing customer support, and considering long-term partnership potential are key factors to consider. Remember to conduct thorough research, seek references, and make an informed decision that aligns with your specific requirements. With the right supplier by your side, you can ensure a steady supply of high-quality aluminum sheets and build a fruitful long-term partnership.