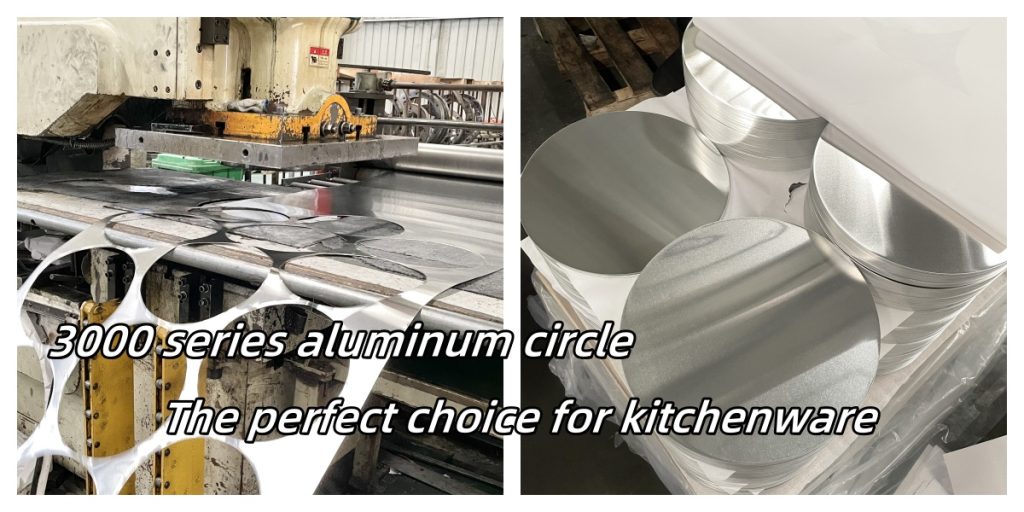

In the kitchenware manufacturing industry, 3000 series aluminium alloys (such as 3003, 3004, and 3005) have become one of the most popular materials due to their excellent strength, corrosion resistance, and machinability. Whether for household cookware, baking moulds, or commercial kitchen equipment, 3000 series aluminium alloys have secured a central position in the industry due to their high cost-effectiveness, safety, and durability.

Physical Performance Advantages of 3000 Series Aluminium

3000 series aluminium alloys (such as 3003, 3004, and 3005) have become the ideal material for modern kitchenware manufacturing due to their unique manganese (Mn) strengthening properties.

Lightweight and Strength Balance

With a density of just 2.73 g/cm³, it is 66% lighter than stainless steel, giving kitchenware a lightweight design. This not only reduces transportation costs but also significantly reduces the weight of kitchenware, making single-handed operation more effortless. The manganese (Mn) reinforcement achieves a tensile strength of 150–220 MPa. For example, a wok can withstand 100,000 stir-fries without deformation.

Excellent Thermal Conductivity

The 3000 series aluminium has a thermal conductivity of up to 220 W/(m·K). As kitchenware, it heats up three times faster than stainless steel and saves 15% energy.Additionally, experiments have proven that the temperature uniformity of 3000 series aluminium kitchenware is outstanding: the temperature difference between the centre and edge of a frying pan is ≤8°C. Its exceptional performance makes it an economical and efficient choice.

Food-grade corrosion resistance

The food-grade corrosion resistance of 3000 series aluminium meets food safety standards such as FDA, GB 4806.9, and LFGB. The natural oxide film and manganese (Mn) elements work synergistically to ensure no perforation after 500 hours of salt spray testing.

Superior processing performance of 3000 series aluminium

Exceptional plastic deformation capability, capable of handling various shapes with ease

3000 series aluminium in the H24 condition maintains an elongation rate of 8-12%, balancing strength and formability. It can easily achieve complex processes such as deep drawing and spinning. 3003 aluminium circle plates can achieve a depth-to-diameter ratio of 1:1.5, enabling one-piece moulding for soup pots and significantly reducing scrap rates.

Outstanding precision punching performance, significantly increasing processing efficiency

No secondary grinding is required on the edges of kitchenware, reducing processing steps. Additionally, the shear strength is only one-third that of stainless steel, with die-cutting energy consumption reduced by 40%. Data on die-cutting gaps, burr height, and surface finish quality all significantly outperform commonly used 304 stainless steel.

Strong compatibility with surface treatments, perfectly suited for various surface treatments

Anodising, coating adhesion, electrolytic polishing, micro-arc oxidation… The 3000 series aluminium discs can easily handle these processes, consistently achieving mirror-like, ceramic-like surfaces, metallic luster, and other surface effects, perfectly suited for various kitchenware manufacturing processes.

Table1: Typical applications of 3000 series aluminium circle in the kitchenware industry

| Application Areas | Performance Advantages | Typical Parameters |

| Wok/Frying Pan | Strong deformation resistance, no deformation after 100,000 stir-frying cycles | Thickness 2.5-3.0mm |

| Soup Pots/Milk Pots | Excellent deep-drawing performance, high yield rate for one-piece moulding | Thickness 2.5-3.0mm |

| Baking Moulds | High-temperature resistance up to 250°C, smooth demoulding | Thickness: 0.8-1.5 mm |

| Induction Cooker-Specific Pots | ddy current thermal efficiency up to 90%, uniform heating | Thickness: 2.5-4.0 mm |

Purchasing 3000 series aluminium discs from YSA offers a superior experience

As a professional aluminium supplier, Henan Yongsheng Aluminium Industry deeply understands the stringent requirements of kitchenware manufacturing, providing you with high-performance, stable-quality 3000 series aluminium disc solutions.

Strict quality control ensures product quality

Our factory specialises in aluminium manufacturing. Our 3000 series aluminium discs (3003/3004/3005) strictly adhere to international standards, employing advanced production processes to ensure precise thickness tolerances, excellent surface finish, and flat sheet profiles, ensuring the quality of your products.

Production capacity assurance, timely delivery

With robust production capacity and over 1,000 tonnes of aluminium disc inventory, we can support large orders, eliminating concerns about stockouts. We respond efficiently to ensure your urgent orders are processed quickly.

Deep customisation, unlocking product potential

Based on your specific requirements (such as special dimensions, tolerances, surface conditions, and packaging methods), we offer professional solutions, supporting full-specification customisation for diameters ranging from 80 to 1,000 mm and thicknesses from 0.13 to 6.5 mm, providing you with an excellent ordering experience and customising your exclusive products.

Value co-creation, achieving long-term mutual benefit

We understand that the essence of B2B collaboration is mutual success. By choosing us, you will gain:

Scalable procurement and lean production, offering you the best prices

High-quality customisation services to optimise your product cost structure

Transparent supply chain management, allowing you to monitor your goods

Table2: Technical Parameters Overview: Key Indicators of 3000 series Aluminum circle

| Parameter Name | Typical Value/Range | Core Value for kitchenware |

| Mn Content | 1-1.5% | Forms a reinforced phase, extending the service life of kitchenware |

| Density | 2.73 g/cm³ | Significantly lighter weight, reducing overall cost |

| Thermal conductivity | 190 W/(m·K) | Heating efficiency is three times higher than stainless steel |

| Tensile strength | 180 – 220 MPa | Good balance of strength and ductility, easy to process and form |

| Elongation | 8-12%(H24-state) | Excellent deep drawing performance, enabling a depth-to-diameter ratio of 1:1.5 |

| Surface roughness | ≤0.8μm | Ceramic coating adhesion improved by 30% |

| Conventional thickness | 0.13mm – 6.5mm | Covers the vast majority of kitchenware application requirements |

| Conventional diameter | 80mm – 1000mm | Flexibly adapts to different kitchenware designs |

Summary

In the kitchenware manufacturing industry, 3000 series aluminium discs (3003/3004/3005) have become the material of choice due to their high strength, excellent thermal conductivity, food-grade safety, and superior processing performance. Whether it’s for household frying pans, commercial griddles, or high-end baking moulds, 3000 series aluminium discs can meet stringent manufacturing requirements while balancing cost-effectiveness and long-term durability.

YSA specialises in the aluminium industry, focusing on providing high-quality 3000 series aluminium discs that meet the stringent requirements of kitchenware manufacturing. We have a comprehensive quality control system, stable supply capabilities, and a professional service team to support you every step of the way.

If you are interested, contact us immediately, and we will respond promptly to help you create more competitive products!