Aluminum sheet roll, often called aluminum coil. It is processed by casting and rolling mill after rolling, stretch bending and straightening. One of the aluminum metal products for shearing. There are many types of processing techniques for aluminum coils, common ones include cutting, die-casting, welding, drawing, etc. Widely used in electronic machinery, packaging, construction engineering, equipment and other fields. This article will start with the aluminum processing technology and explain in detail the manufacturing process of aluminum sheet roll:

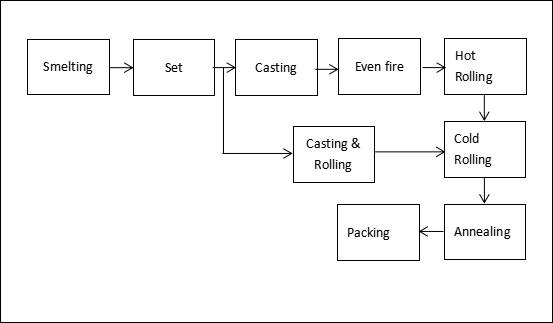

2 Main Production Lines for Aluminum Sheet Rolls

The DC (direct current) and CC (continuous casting and rolling) production lines of aluminum sheet rolls are two common aluminum sheet roll production processes, and they have their own unique characteristics and applicable scenarios. Here are their detailed descriptions:

DC (direct current) production line: The DC production line uses aluminum liquid obtained from aluminum ingots through electrolytic refining, which is continuously cast into aluminum sheet roll raw materials through a continuous casting machine, and then processed through hot rolling, cold rolling and other processes. The chemical composition and physical properties of aluminum sheet rolls rolled by the DC process have good stability and consistency, good surface quality, high brightness, strong bending and tensile properties, and are suitable for projects requiring large-size coils.

CC (continuous casting and rolling) production line: The CC production line is formed by pouring liquid aluminum into a continuous casting machine, quickly solidifying it into an aluminum slab, and performing heating and cold rolling through the continuous rolling machine. The production process of the CC process is continuous, the production efficiency is high, and the supply capacity of aluminum sheet roll is strong. Its microstructure is dense, the grains are fine, and the strength is high, which can meet the demand for high-strength materials. At the same time, the production cost is relatively low, making it suitable for mass production and large-scale processing. It can produce thinner aluminum sheet rolls, with common specifications ranging from 0.2 mm to 6 mm, and is suitable for light industrial fields that require thin sheets.

Detailed Explanation Of Aluminum Sheet Roll Production:

Aluminum alloy cold rolling is generally divided into: melt casting – hot rolling – cold rolling – finishing.

Melt casting is to create an alloy whose composition meets the requirements and the purity of the melt is high. Melting set furnace temperature is generally 1050 ° C, control the temperature of the metal does not exceed 770 ° C; in 735 ° C or so for slagging operation, convenient slag-liquid separation, refining is generally used in the way of secondary refining, a refining plus solid refining agent, and thorough refining using gas refining method, inverted furnace static generally 30Min-1h need to be casting in a timely manner, otherwise need to be re-refined. In the casting process should also constantly add Al-Ti-B wire, used to refine the grain.

Hot rolling refers to rolling above the recrystallization temperature of the metal. The process is generally: ingot – milling – heating – hot rolling – hot finishing – unloading coil. Milling is to facilitate the hot rolling process, heating is to provide a softening of the organization, the temperature is generally between 470 ° C -520 ° C, heating time in 10h-15h, otherwise it may be overcooked, coarse organization. Hot rolling can improve the process performance of metals and alloys, reduce or eliminate casting defects.

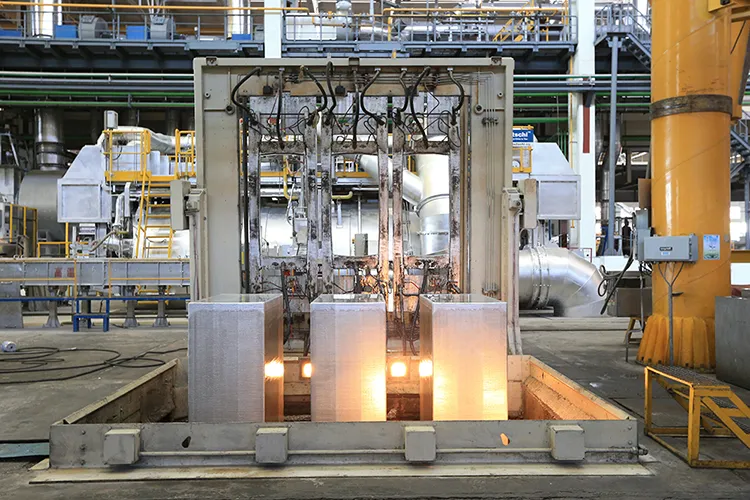

Among them, when casting and rolling, the temperature is generally between 680°C-700°C. The casting and rolling process requires strict control of the front box level to prevent low level. The surface quality of products produced by casting and rolling is generally relatively low, and generally cannot meet products with special property requirements.

Cold rolling refers to the rolling production mode below the recrystallization temperature, the rolling process will not appear dynamic recrystallization, the temperature rises up to the recovery temperature, cold rolling appears to work hardening state, work hardening rate is large. Cold rolled coils have high dimensional accuracy, good surface quality, uniform organization and properties, with heat treatment can be obtained in various states of the product. Cold rolling can also be rolled out of thin strip, while the existence of deformation energy consumption and processing of the shortcomings of more channels.

Finishing is to make the cold rolled sheet to meet the customer’s requirements for processing, to facilitate subsequent processing. Finishing equipment can correct the defects produced during the hot rolling and cold rolling production process such as cracked edges, oil, poor plate shape, residual stress and so on. The finishing process involves a number of equipment, mainly cross-cutting, longitudinal shearing, bending and straightening, annealing furnace, slitting machine and so on. Can ensure that the coil, sheet without burrs, stacked neatly, good surface quality, plate shape and so on.

This process is the most important is to pull the bending and annealing, bending is straightened by stretching to get a good shape of the plate, to avoid in the hot rolling, cold rolling process, because of the temperature, the rate of underpressure, the process of cooling improper control of longitudinal uneven extension and internal stresses caused by defective materials.

The purpose of annealing is to eliminate cold rolling hardening, to get the mechanical properties required by customers. Annealing method using differential temperature annealing or constant temperature annealing, generally the longer the holding time, the better the specified non-proportional elongation strength of the product, at the same time, as the temperature rises, the tensile strength and yield strength continues to decline.

YSA is a leading professional aluminum coil supplier, providing aluminum coil cutting, color coating, oxidation and other processing services. With 23 years of production and processing experience and professional knowledge, we insist on providing customers with all assistance. If you are looking for a reliable supplier to meet your aluminum coil needs, please contact Yongsheng today for a quote!

FAQ:

What size are aluminum coils?

Common thicknesses for aluminum sheet rolls range from 0.2mm-6mm or even larger. The width of the aluminum coil is determined by the intended use and can range from a few centimeters to several meters. For example, common widths for aluminum coils used in construction may be 1,200mm or 1,500mm.

Is aluminum safe to put in your body?

Aluminum is a naturally occurring element in the environment and is commonly used in a variety of products, including cookware, food packaging, antacids and cosmetics. It is also used as an adjuvant in some vaccines to enhance immune responses. These aluminum products that directly act on the human body generally undergo strict safety testing and are regulated by organizations such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA), and are safe and harmless.