In the ever-evolving pharmaceutical industry, packaging plays a crucial role in preserving the efficacy and safety of medications. Oral liquid capsules, which are preferred for their convenience and easy administration, rely heavily on high-quality materials for their production. One such material is 8011 aluminum foil, renowned for its excellent barrier properties and versatility. This article will explore the benefits, applications, and manufacturing processes of 8011 aluminum foil in the production of oral liquid capsules.

What is 8011 Aluminum Foil?

8011 aluminum foil is a specific alloy of aluminum that delivers exceptional properties for packaging applications. Commonly used in the pharmaceutical and food industries, 8011 alloy foil is characterized by its aluminum composition, which typically includes traces of iron and silicon. This composition enhances the material’s strength, ductility, and barrier capabilities, making it an ideal choice for packaging oral liquid capsules.

Benefits

1. Superior Barrier Protection: One of the standout features of 8011 aluminum foil is its excellent barrier properties against moisture, light, and oxygen. These properties are critical in preserving the stability and potency of oral liquid formulations, preventing degradation and contamination.

2. Lightweight and Durable: Unlike heavier packaging materials, 8011 aluminum foil is lightweight, allowing for reduced shipping costs and easier handling. Despite its lightness, it is robust enough to withstand the rigors of transportation and storage.

3. Non-Toxic and Safe: Being non-toxic, 8011 aluminum foil is safe for use in pharmaceutical applications. This ensures that it meets health regulations and standards, making it suitable for packaging various oral liquid medications.

4. Ease of Printing and Branding: The surface of aluminum foil can be easily printed on, enabling pharmaceutical companies to include necessary information about the medication, such as dosage, usage instructions, and branding elements. This enhances product visibility and consumer awareness.

5. Recyclability: Aluminum is a highly recyclable material. Using 8011 aluminum foil contributes to environmentally sustainable practices within the pharmaceutical industry, appealing to eco-conscious consumers.

Applications of 8011 Aluminum Foil in Oral Liquid Capsules

8011 aluminum foil is commonly utilized in various pharmaceutical applications, particularly in oral liquid capsules, including:

– Soft Gel Capsules: 8011 aluminum foil is often used as a protective layer in soft gel capsules, ensuring the contents are securely sealed while maintaining their potency.

– Blister Packs: The foil is widely used in the production of blister packs, which are designed to protect individual capsules from environmental factors, ensuring safe and effective delivery of medications.

– Pouches: For liquid formulations, 8011 aluminum foil can be used to produce pouches that provide an extra layer of protection against moisture and light, preserving the integrity of the contents.

Manufacturing Process of 8011 Aluminum Foil

The production of 8011 aluminum foil involves several key steps:

1. Alloy Production: The process begins with the creation of the 8011 aluminum alloy, which includes specific proportions of aluminum, iron, and silicon.

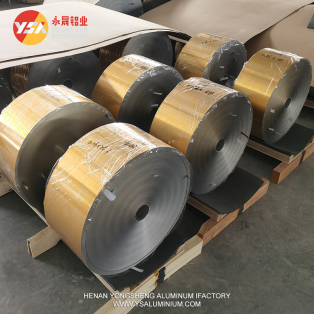

2. Rolling: The alloy is then rolled into thin sheets through a series of processes involving heated and cold rolling, which helps achieve the desired thickness and surface quality.

3. Annealing: The rolled foil undergoes an annealing process, where it is heated to enhance its ductility and formability, making it easier to work with in manufacturing processes.

4. Cutting and Shaping: The rolled foil is cut into specific sizes and shapes as per the requirements for different packaging applications, including blister packs or pouches.

5. Quality Control: Rigorous quality checks are conducted to ensure that the foil meets industry standards regarding thickness, strength, and barrier properties.

Conclusion

8011 aluminum foil is a fundamental material in the packaging of oral liquid capsules, providing excellent barrier protection, durability, and safety. As the demand for effective and user-friendly medication continues to grow, the importance of high-quality packaging materials like 8011 aluminum foil cannot be overstated. By ensuring that oral liquid formulations remain stable and uncontaminated, this foil enhances the overall patient experience and contributes to better health outcomes!