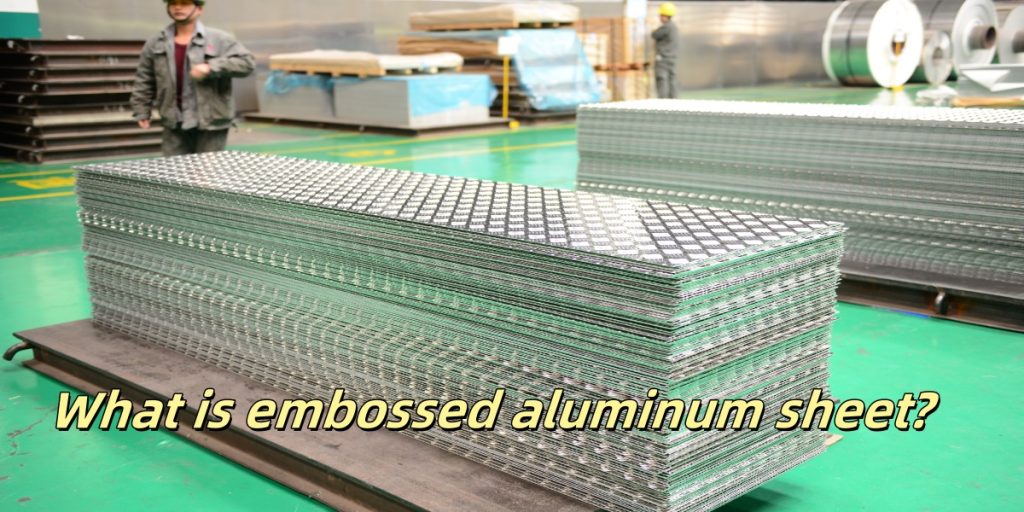

Embossed aluminum sheet is a functional decorative material created by precision mechanical pressing onto an aluminum or aluminum alloy substrate to create a three-dimensional pattern. It perfectly blends the strength of metal with the aesthetic appeal of art, making it a “hidden champion” in applications such as architectural curtain walls, rail transit, and high-end home appliances. This article will provide an in-depth analysis of its core production process.

Embossed Aluminum Sheet Processing Step-by-Step

Embossed Aluminum Sheet Raw Material Selection

Table 1:

| Alloy Grade | Main Components | Characteristics | Typical Applications |

| 1100 | Al ≥ 99.0% | High ductility, easy processing | Interior decoration, lighting |

| 3003 | Al-Mn alloy | Balanced strength and formability | Building curtain walls, vehicle interiors |

| 5052 | Al-Mg alloy | High corrosion resistance, good weldability | Ships, outdoor facilities |

Pretreatment Cleaning

- Purpose: Remove oil and oxide layers to ensure uniform embossing.

- Steps: Alkaline degreasing → Water washing → Acid etching → Water washing → Passivation, chemical conversion coating, and enhanced adhesion.

- Key Parameter: Surface cleanliness must meet Sa 2.5 (ISO 8501 Standard).

Annealing Treatment

- Purpose: Eliminates internal stress in the aluminum sheet, increases elongation by 30%-50%, and prevents cracking during embossing.

- Process: Heating to 300°C-400°C under inert gas, maintaining temperature, and then slowly cooling.

How to Form Patterns on Embossed Aluminum Sheets

The embossing process uses a high-precision roller system to achieve “metal relief.”

Table 2:

| Process Parameters | Control Range | Impact Dimensions |

| Embossing Roller Pressure | 200-1000 tons | Pattern Depth and Clarity |

| Roller Temperature | 50-80°C | Preventing Aluminum from Sticking to the Roller |

| Line Speed | 5-30 m/min | Production Efficiency and Texture Uniformity |

| Pattern Depth | 0.02-0.5 mm | Anti-slip Properties and Visual Effects |

Key Technologies

- Convexity Compensation Technology: Increases the roller center diameter by 0.02-0.05mm to offset pressure deformation.

- Hydraulic Servo System: Dynamically adjusts the roller gap with an accuracy of ±0.01mm.

- Laser Alignment Device: Ensures precise overprinting of composite patterns with an error of <0.1mm.

- Example: Diamond-patterned aluminum sheet for high-speed rail carriages, with a pattern depth of 0.3mm, maintains a friction coefficient above 0.65 after 100,000 friction cycles (ISO 10545 standard).

Surface Treatment of Embossed Aluminum Sheet

Embossed aluminum sheet achieves functional upgrades through coating.

Table 3:

| Treatment Method | Key Process Points | Key Performance Comparison |

| Anodizing | Film thickness 10-25μm, pore sealing | Hardness HV ≥ 300, scratch resistance |

| PVDF Spraying | Two-coat, one-bake process, film thickness ≥ 25μm | Weatherability > 20 years (ASTM G154) |

| Polyester powder coating | Electrostatic spraying, curing at 200°C | 30% cost reduction, rich colors |

Finishing Quality Inspection of Patterned Plate

Finishing Process

- Tension Straightening: Eliminates corrugated deformation within 0.5mm/m.

- Flying Shear Cutting: Laser-positioned cutting, length tolerance ±0.3mm.

- Protective Film: Blue waterproof and moisture-proof hollow plastic sheet to prevent transportation scratches.

Table 4: Strict Testing Standards

| Test Items | Method | Acceptance Criteria |

| Pattern Depth | Laser Profilometer Scanning | Tolerance ±0.05mm |

| Coating Adhesion | 100-grid Knife Cross-cutting Method | ≥4B (ISO 2409) |

| Corrosion Resistance | Neutral Salt Spray Test | ≥3000 hours without blistering |

| Color Difference | Colorimeter Testing | ΔE ≤1.5 |

Embossed Aluminum Sheet’s Future-Oriented Process Evolution

Digital Embossing Technology

- Using laser-engraved ceramic rollers, achieves 1000 DPI ultra-high-precision textures at 1000 DPI.

- Pattern switching time reduced from 72 hours to 2 hours.

Low-Carbon Manufacturing Process

- Water-based paint replaces solvent-based paint.

- Recycled aluminum utilization increased to 70%, reducing carbon footprint by 45%.

Smart Factory System

- IoT monitors embossing roller temperature and pressure fluctuations in real time.

- AI vision automatically identifies surface defects.

The manufacture of embossed aluminum sheet is a dance of precision mechanics and materials science—from molecular reassembly in a 300°C annealing furnace, to the development of patterns under a thousand-ton press, to the microscopic protection of nano-coatings, every step embodies the ultimate pursuit of industrial aesthetics. Data shows that the global embossed aluminum sheet market is expanding at a compound annual growth rate of 6.8%, driven by the strong drive of continuous innovation in manufacturing processes.

When the building’s curtain wall casts diamond-shaped shadows in the sunlight, and when the beaded floor of a high-speed rail carriage remains as smooth as new after billions of footsteps, what we see is not only the physical deformation of metal, but also the crystallization of human wisdom that integrates rational craftsmanship with emotional design.