Perforated aluminum sheets, also known as preformed aluminum sheets, are highly multipurpose materials that find wide use in many kinds of industries. The feature of the perforated aluminium sheets is their unique perforated patterns, allowing for improved functionality, design flexibility, and extensive applications. In this article, we will delve into the features and applications of perforated aluminum sheets, highlighting their importance in diverse industries.

Understanding Perforated Aluminum Sheets

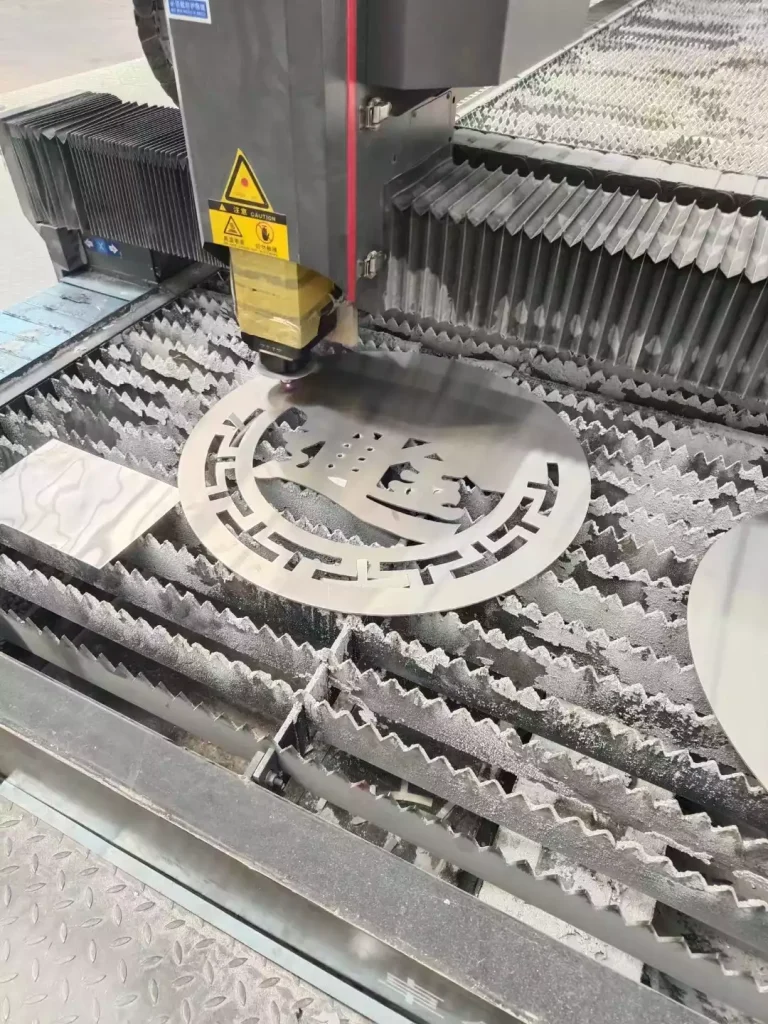

High-quality aluminum alloys that go through a sophisticated manufacturing process are used to create perforated aluminum sheets. To generate a pattern of holes in various shapes and sizes, the sheets are precisely punched. The material’s attributes are enhanced and given distinctive qualities by the perforation process.

Preformed aluminum sheets show excellent features and characteristics. They are known for their durability and strength, making them suitable for both indoor and outdoor applications. Although their robustness, they are lightweight, making installation and handling convenient. What’s more, perforated aluminium sheets are highly resistant to corrosion, making sure long-term reliability even in challenging environments. Furthermore, they offer excellent heat and sound insulation properties, conducive to energy efficiency and acoustic control in different settings. Lastly, preformed aluminum sheets can be customized to meet specific aesthetic requirements, making them a popular choice for architects and designers.

Applications of Perforated Aluminum Sheets

- Architecture and Construction Industry: Preformed aluminum sheets are extensively used in architectural applications. They are employed in facades and cladding systems, adding a visually appealing and modern touch to buildings. Additionally, they are used in balustrades and railings, providing both safety and an elegant appearance. Sunscreens and partitions are other common applications, allowing for light and air flow while maintaining privacy.

- Automotive Industry: Perforated aluminium sheets find their place in the automotive sector. They are employed in grilles and air ventilation systems, ensuring proper airflow and cooling for engines and radiators. Furthermore, they are used for speaker covers and interior decorations, enhancing the aesthetics of vehicle interiors. By the way, the application of 5052 aluminium sheet in the automotive industry also play an important role.

- Industrial and Manufacturing Sector: The industrial and manufacturing sector benefits from the versatility of preformed aluminum sheets. They are widely used as filters and screens, allowing for the separation of solids and liquids in various processes. Perforated sheets are also utilized in conveyors and storage systems, providing efficient material handling solutions. Moreover, they find application in acoustic panels and noise reduction solutions, contributing to a safer and more comfortable working environment.

- Furniture and Interior Design: In the realm of furniture and interior design, perforated aluminium sheets offer numerous possibilities. They can be used as room dividers and wall coverings, creating visually striking and functional spaces. Decorative panels and ceiling tiles made from preformed aluminum sheets add a unique touch to interior designs, combining aesthetics with practicality.

Benefits of Perforated Aluminum Sheets

The use of perforated aluminum sheets brings several advantages:

- Enhanced Functionality and Performance: The perforated patterns in preformed aluminum sheets allow for improved functionality in various applications. They enable the passage of air, light, and sound while maintaining structural integrity.

- Improved Air and Light Flow: The perforations in the sheets facilitate the flow of air, promoting ventilation and reducing the risk of condensation. Similarly, they allow natural light to penetrate spaces, reducing the need for artificial lighting and enhancing energy efficiency.

- Noise Reduction and Acoustic Control: The perforated patterns in preformed aluminum sheets aid in noise reduction by absorbing and diffusing sound waves. This property is particularly useful in environments where noise control is crucial, such as concert halls, office spaces, and manufacturing facilities

- Visual Appeal and Design Flexibility: Perforated aluminium sheets offer a wide range of design options, enabling architects and designers to create unique and visually appealing structures. The patterns can be customized to suit specific aesthetic requirements, adding a touch of elegance and sophistication to any project.

- Energy Efficiency and Sustainability: The lightweight nature of preformed aluminum sheets contributes to reduced energy consumption during transportation and installation. Additionally, aluminium is a highly recyclable material, aligning with sustainable practices and environmental consciousness.

Factors to Consider When Choosing Perforated Aluminum Sheets

When selecting preformed aluminum sheets, several factors should be taken into account:

- Hole Patterns and Open Area: The choice of hole patterns and open area depends on the intended application. Different hole shapes and sizes offer varying levels of functionality and aesthetics.

- Sheet Thickness and Strength: The thickness of the sheet determines its strength and durability. It is important to select a thickness that can withstand the intended use and environmental conditions. Different thicknesses of aluminum foil are suitable for different scenarios. For different scenarios, you’d better choose the appropriate high quality aluminum foil.

- Surface Finish and Coating Options: Surface finishes and coatings provide additional protection against corrosion and enhance the material’s aesthetic appeal. Consider the desired finish and coating options based on the application and environment.

- Customization and Design Possibilities: Preformed aluminum sheets can be customized to fit specific project requirements. Consider whether customization options are available to achieve the desired design and functionality. Of course, In regard to the application of regular aluminum sheets, this factor also needs to be taken into account.

- Budget and Cost Considerations: Factor in the budget and cost implications when selecting perforated aluminium sheets. While considering the desired features and specifications, it is essential to find a balance between quality and affordability. By the way, although the hardness of 6000 series aluminum sheets is not as high as other aluminum alloys, it is suitable for structural components in the aerospace, automotive and marine industries, and it offers a good balance of performance and cost effectiveness without creating additional material costs.

Installation and Maintenance of Perforated Aluminum Sheets

Proper installation techniques are crucial to ensure the longevity and performance of preformed aluminum sheets. Follow manufacturer guidelines and consult professionals if necessary to ensure the correct installation process. Additionally, regular cleaning and maintenance are important to preserve the appearance and functionality of perforated aluminium sheets. Use appropriate cleaning agents and methods based on the specific finish and coating of the sheets. It is also important to observe safety precautions and guidelines when handling and working with perforated aluminium sheets.

Perforated aluminium sheets, or preformed aluminum sheets, are versatile materials that offer a wide range of applications in various industries. Their unique perforation patterns contribute to enhanced functionality, design flexibility, and aesthetic appeal. From architecture and construction to automotive and manufacturing sectors, perforated aluminium sheets find use in diverse applications. The benefits they bring, such as improved air and light flow, noise reduction, visual appeal, energy efficiency, and sustainability, make them a preferred choice for many projects. When selecting perforated aluminium sheets, consider factors like hole patterns, sheet thickness, surface finish, customization options, and budget. Proper installation and maintenance are crucial to ensure the longevity and performance of preformed aluminum sheets. With their versatility and numerous advantages, perforated aluminium sheets continue to play a significant role in shaping our built environment and industrial landscape.