Introduction

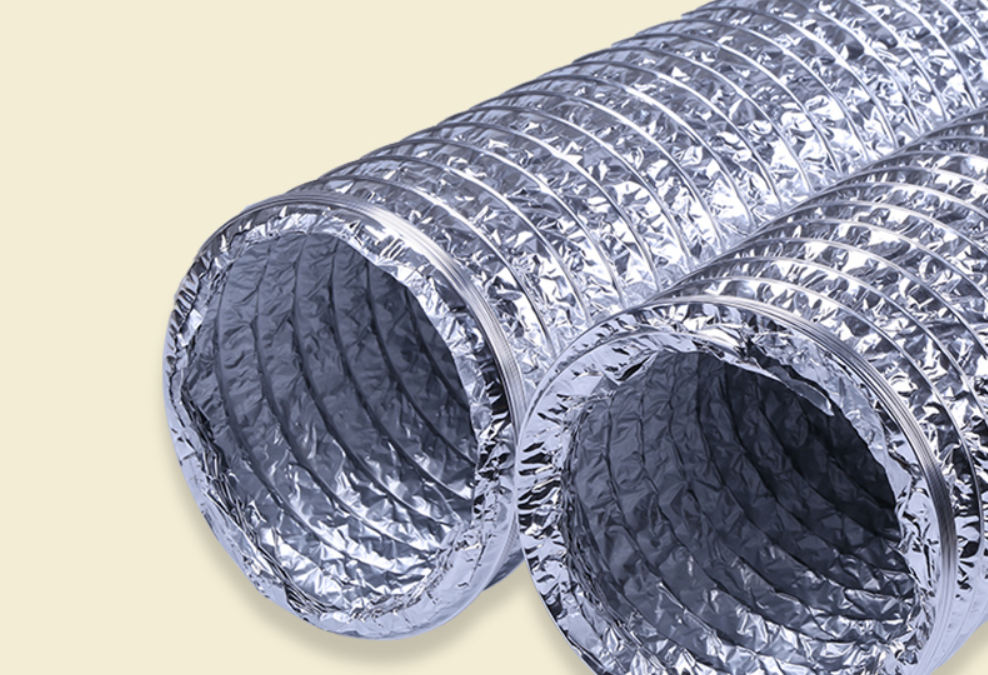

Aluminum foil air ducts play a crucial role in HVAC systems, facilitating the efficient flow of air throughout buildings. However, choosing the proper aluminum foil air ducts can be challenging, considering the variety of options available in the market. In this guide, we’ll explore the key factors to consider when selecting aluminum foil air ducts to ensure optimal performance and durability.

Size and Diameter

The first step in choosing aluminum foil air ducts is determining the appropriate size and diameter for your HVAC system. Consider factors such as the airflow requirements, the size of the space being serviced, and any specific design constraints. Selecting ducts with the right diameter ensures efficient airflow and minimizes resistance within the system.

Material Quality

The quality of the aluminum foil used in air ducts significantly impacts their durability and performance. Look for ducts made from high-quality, heavy-duty aluminum foil that is resistant to tears, punctures, and corrosion. Additionally, ensure that the foil complies with relevant industry standards for strength and durability.

Insulation Thickness

Insulated aluminum foil air ducts offer enhanced thermal efficiency and noise reduction compared to uninsulated ducts. When choosing air ducts, consider the insulation thickness and R-value to meet the thermal insulation requirements of your HVAC system. Thicker insulation provides better thermal performance and helps prevent heat loss or gain during air distribution.

Flexibility and Flexibility Rating

Flexibility is essential, especially in installations that require navigating tight spaces or around obstacles. Choose aluminum foil air ducts with sufficient flexibility to bend and curve as needed without compromising airflow or structural integrity. Additionally, consider the flexibility rating, which indicates the duct’s ability to withstand repeated bending cycles without damage.

Fire Resistance and Safety Compliance

Fire resistance is a critical consideration when selecting aluminum foil air ducts, particularly in commercial and residential buildings where fire safety regulations apply. Look for ducts that meet relevant fire resistance standards, such as ASTM E84 or UL 181, to ensure compliance with safety regulations and minimize the risk of fire hazards.

Installation Compatibility

Consider the ease of installation and compatibility with existing HVAC components when choosing aluminum foil air ducts. Look for ducts that feature user-friendly installation mechanisms, such as snap-lock or zip ties, to simplify the installation process and minimize labor costs. Additionally, ensure that the ducts are compatible with the connectors, fittings, and sealing materials required for airtight connections.

Manufacturer Reputation and Warranty

Lastly, consider the reputation of the manufacturer and the warranty offered with the aluminum foil air ducts. Choose reputable manufacturers with a track record of producing high-quality ducting products and providing reliable customer support. Additionally, inquire about the warranty coverage for defects or premature failure to ensure long-term peace of mind.

Conclusion

Selecting the proper aluminum foil air ducts is essential for ensuring efficient airflow, thermal performance, and safety in HVAC systems. By considering factors such as size, material quality, insulation thickness, flexibility, fire resistance, installation compatibility, manufacturer reputation, and warranty coverage, you can make informed decisions and choose ducts that meet your specific requirements. Investing in high-quality aluminum foil air ducts not only enhances the performance and longevity of your HVAC system but also contributes to improved indoor air quality and occupant comfort.