What Is Orange Peel Embossed Aluminum?

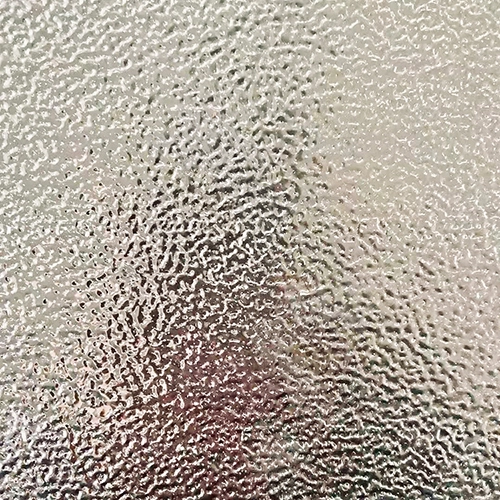

Orange peel embossed aluminum is a type of aluminum with a unique texture that resembles the peel of an orange. This texture is achieved through an embossing process that involves pressing the aluminum sheet with a patterned roller to create a raised surface. Raised surfaces consist of small round or oval bumps of uniform size and shape, giving the material a unique and aesthetic appearance.

Manufacturing Of Orange Peel Embossed Aluminum:

The production process for orange peel embossed aluminum begins with a sheet of aluminum alloy, which is then cleaned and chemically treated; the next step is the embossing process, which involves passing the aluminum sheet through a series of rollers with a patterned surface. The pattern roller has a raised surface that presses against the aluminum sheet to create a raised pattern of small, round or oval bumps, similar to the texture of an orange peel. The embossed sheet is then trimmed and cut to size; the final step in the production process is quality control. Manufacturers use a variety of quality control techniques to ensure finished products meet industry standards. These measures include visual inspection of materials, dimensional measurements and chemical analysis.

Orange Peel Embossing Specifications:

Orange peel embossed aluminum can be produced in various specifications according to the specific application and requirements of the end user. Specifications may include: Thickness (0.01mm to 3mm or more); Width (10mm to 2000mm or more); Length (hundreds of millimeters to several meters or more); Pattern (varies according to end user requirements); Alloy (e.g. 1000 series , 3000 series, and 5000 series); Finishes (e.g. milled, anodized, and painted); Colors (depending on production process and end-user requirements).

Properties Of Orange Peel Embossed Aluminum:

Orange peel embossed aluminum is ductile, formable, thermally conductive, chemically resistant, non-slip and has good electrical conductivity. Its most important property is aesthetic: the unique texture of orange peel embossed aluminum gives it a distinctive appearance that sets it apart from other materials. Highly prized for its enhanced aesthetic appeal, it is the ideal material for use in appearance-conscious applications.

Applications Of Orange Peel Embossed Aluminum:

Orange peel embossed aluminum is used for flooring, panels and trim in the transportation industry. The embossed surface enhances slip resistance and is ideal for flooring applications such as buses, trains and airplanes. Used in the construction industry for roofing, siding and insulation. In the household appliance industry, it is used to manufacture refrigerators, ovens, air conditioners and other electrical appliances. Orange peel embossed aluminum is also used in other industries such as the marine industry for boat flooring and trim. It is also used in the lighting industry for the manufacture of light reflectors and diffusers.

Orange Peel Embossing Manufacturer In China:

Yongsheng Aluminum can provide you with orange peel embossed aluminum: 1000 series, 3000 series, 5000 series. Commonly used patterns include classic, deformed, diamond, 1-5 strips, checkered patterns, etc. Users can also customize according to project conditions. Eternal orange peel embossing is widely used in refrigerators, wine cabinets, solar panels, decorative aluminum products, lamps, light boxes, disinfection cabinets, kitchen cabinets and central air-conditioning systems and other fields. Due to the particularity of the pattern, it also has good thermal conductivity and heat dissipation performance, and can be used in electrical conductors, light reflectors, lighting equipment, power cables and radiators, etc.

Maintenance And Care Of Orange Peel Embossed Aluminum:

Orange peel embossed aluminium should be cleaned regularly to remove any dirt, dust or other debris that has accumulated on the surface. Use a soft, non-abrasive cloth and a mild detergent solution to clean the surface. Take care to avoid using abrasive cleaners or scrubbers on orange peel embossed aluminium as they can scratch or damage the surface. Avoid using harsh chemicals on orange peel embossed aluminium as they can damage the surface. This includes acidic or alkaline cleaners as well as solvents or other chemicals.

Orange peel embossed aluminium may be scratched or damaged by sharp or rough objects. To protect the surface, avoid placing sharp or rough objects directly on the surface. Also, prevent the surface from coming into contact with corrosive substances such as salt water or acidic liquids. Normally, it should be stored in a dry, cool place to prevent damage and corrosion.

In short, orange peel embossed aluminium is a versatile and durable material that can be used in a wide range of industries. Whether you’re looking for materials for flooring, roofing, packaging or domestic appliances, orange peel embossed aluminium is a reliable and quality choice. If you are looking for a material that combines functionality, durability and aesthetics, then orange peel embossed aluminium is the perfect choice. It has a unique texture and excellent properties that can enhance the performance and appearance of your products while providing long-term reliability and durability. Contact us today for further details on our orange peel embossed aluminium.