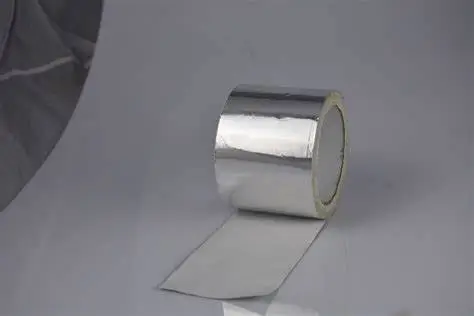

Aluminum foil tape is a general adhesive product and the applications of aluminum foil tape is more and more popular across many kinds of industries. The wide applications of aluminum foil tape is to provide a hard and trustworthy sealing solution. It may apply in HVAC, construction, automotive, electrical, or even arts and crafts. In this article, we will mainly talk about the common applications, maintenance tips and advantages of aluminum foil tape.

What is Aluminum Foil Tape?

Aluminum foil tape is general composed of a thin layer of aluminum foil as the base material and an adhesive layer on one side. The adhesive layer can be various in composition, with options such as acrylic, rubber, or silicone adhesives, each offering different bonding strengths and durability.

The Common Applications of Aluminum Foil Tape

- HVAC industry: Aluminum foil tape plays a important role in sealing air ducts and joints, preventing air leaks, and improving energy efficiency.

- Construction and insulation applications: It is widely used in construction for installing steam expansion, which help control moisture transmission.

- Automotive industry: In the automotive sector, tape is used for repairing and sealing heat shields, protecting electrical components from heat, and providing insulation in engine compartments.

- Electrical and electronic applications: The applications of foil tape serves as an effective EMI/RFI shield, protecting sensitive electronic equipment from electromagnetic interference.

- Arts and crafts and household uses: Foil tape get into world of arts and crafts, where it is used for creating reflective surfaces in photography or adding decorative accents. Aluminum can also be used for meat products packaging, barbecue food packaging, and frozen food packaging in the refrigerator.

Advantages of Aluminum Foil Tape

- Durability and long-lasting performance: Foil tape is famous for its durability and ability to bear hard environment, making sure stress rupture property.

- High resistance to moisture, UV rays, and chemicals: The moisture barrier properties of aluminum foil, coupled with the adhesive’s resistance to UV rays and chemicals, make this tape highly reliable in various settings.

- Excellent temperature and flame resistance: Foil tape is designed to withstand high temperatures, making it suitable for applications where heat resistance is crucial.

- Easy application and removal: Foil tape is easy to handle and apply, thanks to its flexibility and conformability.

- Cost-effectiveness compared to other sealing options: Foil tape offers a cost-effective solution for sealing and insulation purposes, often providing comparable or superior performance to alternative products at a lower price point.

How to Select Aluminum Foil Tape?

- Thickness and width options: Depending on the specific application, different thicknesses and widths of Foil tape may be required to meet the desired performance and sealing requirements.

- The strength of adhesion and compatibility with different surfaces: It is important to consider the strength of adhesion of the tape and ensure compatibility with the surface it will be put to use.

- Compatibility with specific environments or conditions: Certain applications may involve exposure to extreme temperatures, chemicals, or outdoor elements.

- Storage and handling recommendations: Proper storage and handling of aluminum foil tape can contribute to its longevity and effectiveness. Storing the tape in a cool and dry environment, away from direct sunlight, and following the manufacturer’s guidelines for handling will help maintain its quality.

Proper Applications Methods of Aluminum Foil Tape

- Surface preparation and cleaning: Before using aluminum foil tape, it is necessary to make sure that the surface is tidy, dry. Through proper surface practice, the adhesion and validity of the tape will be improved.

- Correct tape placement and securing: Care should be taken when positioning the tape to ensure proper coverage and alignment. It is also important to secure the tape firmly, using firm pressure to ensure a strong bond.

- Overlapping and sealing joints effectively: When sealing joints or overlapping pieces of tape, it is crucial to ensure a tight seal to prevent air or moisture leakage. Properly aligning the tape and using sufficient overlap will help achieve an effective seal.

- Avoiding common mistakes during application: Common mistakes during the application of aluminum foil tape include not removing the release liner properly, applying the tape on wet or dirty surfaces, or not applying enough pressure for proper adhesion. Pay attention to avoid these mistakes will make sure optimal characteristics.

How to Use Aluminum Foil Tape?

- Handling sharp edges and corners: Aluminum foil tape can have sharp edges or corners, which can pose a risk of injury. It is important to solve the tape with rigor and wear proper protective equipment, such as gloves, when necessary.

- Proper ventilation and protection during application: When working with aluminum foil tape in enclosed spaces or areas with poor ventilation, it is important to ensure proper air circulation and, if necessary, wear a mask to prevent inhalation of fumes.

- Compliance with safety regulations and guidelines: Depending on the specific application and industry, there may be safety regulations and guidelines to follow. To ensure a safe working environment, it is necessary to stick to these rules.

How to Save and Separate Aluminum Foil Tape?

- Inspecting and maintaining the tape’s integrity: Regularly inspecting the aluminum foil tape for any signs of damage, wear, or peeling will help identify potential issues early on. Promptly addressing any concerns and replacing the tape when necessary will help maintain its effectiveness.

- Techniques for removing tape residue: When removing aluminum foil tape, there may be some adhesive residue left behind. Using appropriate adhesive removers or techniques, such as applying heat or using a solvent, can help effectively remove the residue without damaging the surface.

- Considerations when reapplying or replacing the tape: When reapplying or replacing aluminum foil tape, it is important to ensure proper surface preparation, including cleaning and removal of any remaining adhesive residue.

Aluminum Foil Tape VS Copper Foil Tape

| Aspect | Aluminum Foil Tape | Copper Foil Tape |

| Material | Aluminum Foil | Copper Foil |

| Conductivity | Lower electrical conductivity | Higher electrical conductivity |

| Shielding Effectiveness | Good for RF signals and EMI | Excellent for electromagnetic interference |

| Durability | Lower electrical conductivity | Resistant to environmental factors, but susceptible to oxidation |

| Applications | HVAC, insulation sealing, general-purpose sealing and wrapping | Electronics, electromagnetic shielding, circuit board repairs, grounding, arts and crafts |

| Cost | Generally more affordable | Tends to be more expensive |

Summary

A useful and necessary adhesive component, aluminum foil tape is employed in many different industries. Due to its composition, characteristics, and advantages, aluminum foil tape is a dependable choice for sealing, insulation, and protection jobs. Optimal performance and longevity are ensured by following the right application procedures, safety precautions, and maintenance procedures. As you probe the world of aluminum foil tape, you’ll find a lot of benefits and creative ways to make use of it in your industry or everyday life.