Early tin foil was made primarily from metallic tin. However, it had significant drawbacks: it was too soft and easily torn, its melting point was only 232°C, and it became brittle when exposed to high temperatures. Furthermore, its residual “tin smell” could easily contaminate food flavors. In 1903, France pioneered the industrial production of aluminum foil. Aluminum foil’s core advantages lie in its high melting point of 660°C, making it resistant to baking and grilling; its excellent ductility, allowing it to be rolled down to a thickness of 0.006mm; and its cost, significantly reduced with the advancement of aluminum smelting technology. By the 1930s, aluminum foil had completely replaced tin foil as the packaging material for butter and cheese in Europe.

The term “tin foil” used today is a remnant of a historical name. China began producing aluminum foil in 1932, and after the reform and opening-up policy, its production capacity leapt to the top globally, accounting for 60%-65% of global production. This confusion in terminology is simply a linguistic imprint of technological evolution.

Aluminum Foil vs Tin Foil: Differences in Raw Materials and Manufacturing Processes

The fundamental difference between the two foil materials begins with the raw materials

- Tin foil: Made from tin metal or tin-aluminum alloy with a purity exceeding 99%. Due to tin’s relatively soft crystal structure, a trace amount of aluminum is added to enhance its strength. However, due to its scarcity (only 0.004% is found in the Earth’s crust), raw material costs remain high.

- Aluminum foil: Made from 3000-series or 8000-series aluminum alloys, it capitalizes on aluminum’s high ductility. The raw material is electrolytic aluminum ingots, melted and cast at 1,450°C, and then rolled. This is a plentiful resource and low cost.

The manufacturing process determines the product’s performance limits

Tin foil pressing bottlenecks

Traditional rolling requires a temperature of 100-150°C to prevent brittle cracking. The lower limit of finished product thickness is approximately 0.03mm. Furthermore, tension control is difficult, making it prone to holes.

Precision Rolling of Aluminum Foil

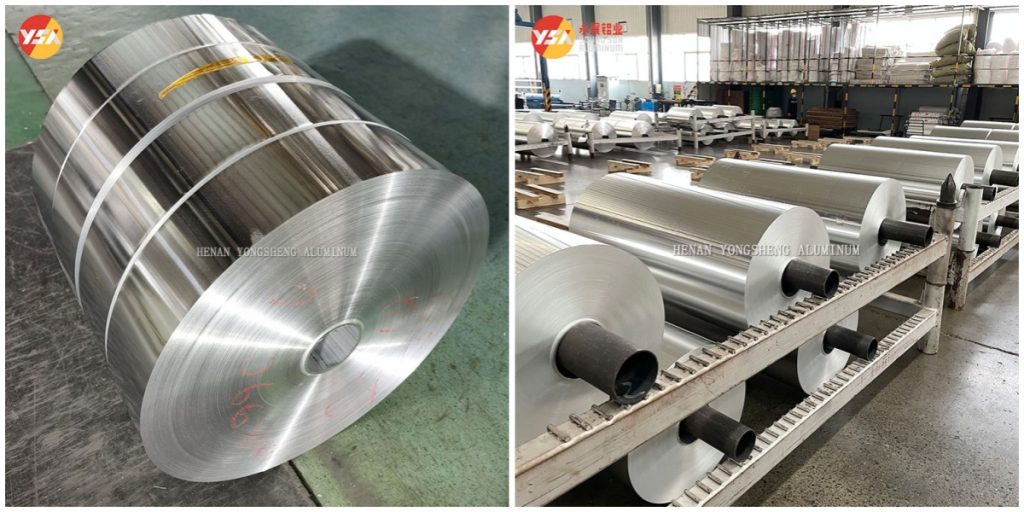

- → Hot Rolling: Aluminum ingots are rolled in multiple passes to a 2-4mm thick coil

- → Cold Rolling: Rolled to 0.1-0.3mm thick using an asynchronous rolling mill at room temperature

- → Annealing: 400°C treatment eliminates stress and improves ductility

- → Finish Rolling: Double-combination rolling breaks the thickness limit, achieving food foil thicknesses of 0.006-0.009mm.

Table 1: Comparison of Industrial Parameters of Aluminum Foil and Tin Foil

| Characteristics | Aluminum Foil | Tin Foil |

| Raw Material Cost | Approximately 7,000 RMB/ton | Over 20,000 RMB/ton |

| Thickness Range | 0.006-0.2mm | ≥0.03mm |

| Pinhole Defect Rate | ≤500/㎡ | Unable to effectively control |

| Packaging | Roll-type | Single-sheet laminated (with interleaved paper for anti-sticking) |

This process difference leads to a divergence in the final product form: Aluminum foil is mostly sold in rolls, accounting for 90% of the market, while tin foil, due to its tendency to stick, must be stacked individually with interleaved paper, significantly increasing packaging costs.

Comparison of Physical and Chemical Properties

The core performance differences between aluminum foil and tin foil directly define the boundaries of their application scenarios. The following table compares key parameters.

Table 2: Comparison of Physical and Chemical Properties of Aluminum Foil and Tin Foil

| Property | Aluminum Foil | Tin Foil | Application Impact |

| Melting Point | 660°C | 232°C | Tin foil softens at 160°C and should not be used in ovens or grills |

| Ductility | Can be stretched 30% without breaking | Poor | Tin foil is difficult to shape and adheres to food |

| Strength | High | Low | Tin foil packaging requires thicker material, increasing costs |

| Appearance | Matte silvery white | High gloss | Tin foil offers better decorative properties |

| Thermal Conductivity | 237 W/(m·K) | 67 W/(m·K) | Aluminum foil accelerates cooking but is prone to localized overheating |

| Barrier Properties | WOT <0.1 g/m²d | WOT approximately 1.5 g/m²d | Aluminum foil’s shelf life is extended by 3-6 months |

| Corrosion Resistance | Surface oxide film resists weak acid | Tin ions rapidly precipitate when exposed to acid | Tin foil poses safety risks when exposed to sauerkraut or lemon juice |

| Density | 2.7 g/cm³ | 7.3 g/cm³ | Aluminum Foil Reduces Shipping Costs by 50% |

Key Performance Analysis

- High-Temperature Stability Difference: Aluminum foil’s melting point of 660°C allows it to withstand conditions such as a 250°C oven and a 400°C charcoal fire. Tin foil, on the other hand, begins to become brittle above 160°C and completely melts at 230°C.

- Barrier Mechanism Comparison: Aluminum foil’s crystal density blocks UV, oxygen, and water vapor. For example, in an aseptic milk carton, a mere 9μm thick aluminum layer can block 99.5% of light and oxygen, extending its shelf life to nine months. Tin foil, however, has a loose structure and numerous pinholes, reducing its barrier efficiency by over 30%.

- Acidic Environment Risk: Both materials may precipitate metals when exposed to acid. However, aluminum, protected by an oxide film, migrates less than 5mg/kg, while tin can precipitate up to 50mg/kg in lemon juice over a two-hour period, exceeding the safety threshold by 10 times.

Safety Considerations for Aluminum Foil and Tin Foil

Metal migration is a common risk for both types of foil, but the mechanisms and severity of harm differ significantly.

Risk Limits of Aluminum Foil

- Alzheimer’s Disease Controversy: Aluminum ions may cross the blood-brain barrier, and long-term excessive intake (>1 mg/kg body weight/week) is associated with cognitive impairment. However, the World Health Organization states that dietary aluminum intake accounts for only 1% of total exposure, and the primary risk comes from aluminum additives, not aluminum foil.

- Acidic Food Taboos: When wrapping foods with a pH below 4, aluminum ion migration increases tenfold. Experiments show that after baking tomato slices wrapped in aluminum foil for 20 minutes, the aluminum content increases from 0.2 mg/kg to 4.5 mg/kg.

- Warning for People with Kidney Disease: People with renal impairment have a reduced ability to excrete aluminum, which may lead to aluminum accumulation in the blood and cause anemia. Such people should avoid cooking with aluminum foil.

The Hidden Dangers of Tin Foil

- Main Cause of Gastrointestinal Irritation: Tin ions irritate the gastrointestinal mucosa, and acute poisoning causes nausea and diarrhea. The EU stipulates that tin residues in canned food must be ≤200mg/kg, while the test value for tin foil-wrapped grilled fish with lemon can reach 350mg/kg.

- The toxic risk of lead-containing tin foil: Some low-quality tin foil contains lead (up to 30%) to reduce costs. Lead, a neurotoxin, can cause intellectual impairment in children. Jiangsu Province, China, has previously uncovered a case of “sacrificial tin foil being diverted to food” with excessive lead levels.

Key Safety Recommendations

- Prohibition Warning: Any product labeled “tin foil” must not come into contact with food to prevent the risk of lead.

- Guidelines for using aluminum foil: Avoid contact with acidic and high-salt ingredients. Cabbage leaves or corn leaves can be used as substitutes.

- Alternative: When acidic seasoning is needed, use a ceramic bowl covered with plastic wrap.

Main Uses and Applications

Aluminum foil has reshaped three major sectors: food packaging, cooking, and industry, thanks to its performance advantages.

Food packaging

- Aseptic long-lasting packaging: The 6.5μm aluminum foil in Tetra Pak packaging blocks light and oxygen, extending the shelf life of milk to nine months.

- Coffee capsules: The aluminum layer prevents aroma evaporation, extending the shelf life to 18 months.

- Chocolate: Aluminum foil prevents the formation of fat frost/sugar frosting, a century-old practice at Swiss Toblerone.

- Qia Qia nuts: Aluminum foil + nitrogen gas barrier provides an 8-month shelf life.

- A lifesaver for oily foods: After switching to aluminum foil packaging, Weilong Konjac Juice saw a 95% reduction in oil leakage and an extension of its shelf life from 3 months to 8 months.

Cooking scenarios

- A must-have for grilling and baking: Wrapping sweet potatoes, enoki mushrooms, and other foods prevents burning and evenly conducts heat, locking in juices.

- Prepared meal containers: Aluminum foil lunch boxes are freezer-resistant from -40°C to 250°C and microwave-safe, making them a top choice for takeout soups like pickled fish and Buddha Jumps Over the Wall.

- Oil-absorbing: Rolling aluminum foil into a ball and unfolding it absorbs 90% of excess oil in soups.

Remaining uses of tin foil

- Cultural offerings for rituals: Traditional burning of tin foil ingots;

- Specific industrial applications: Some low-temperature solders and electronic component pads.

In the future, aluminum foil will evolve into thinner 4μm electrolytic capacitor foil, aluminum-plastic film composites for lithium batteries, and antibacterial coatings. Tin foil will ultimately become a relic of the handicraft era, preserved in historical memory.