Henan Yongsheng Aluminum is a manufacturer of raw materials for aluminum honeycomb panels. We do not produce finished products but only provide raw materials, including aluminum honeycomb alloy panels and aluminum honeycomb core raw materials. Customers are required to process them into honeycomb composite panels of various specifications. Our aluminum alloy raw materials are strong and durable, sold all over the world, and are trustworthy.

| Panel Size | 1200*2400,1400*3000,1200*240,1400*3000,2000*6000 mm,Customized |

| Total Thickness | 10-100 mm |

| Top Sheet Thickness | 0.8-3.0 mm |

| Bottom Sheet Thickness | 0.8-3.0 mm |

| Core Thickness | 0.5-100 mm |

| Sheet Alloy | 1100、3003、3014、5005、5015、6063, etc |

| Core Alloy | 1100、3003、3014、5005、5015、6063, etc |

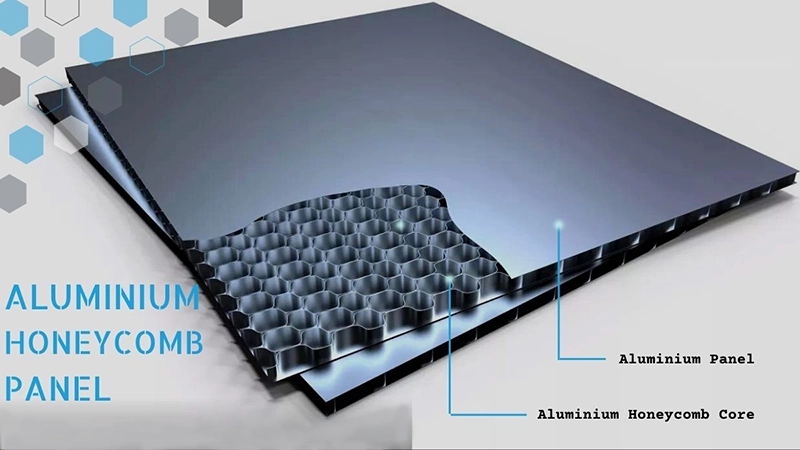

Aluminum Honeycomb Panels Structure

Aluminum Honeycomb Panel: Sturdy

The top and bottom sheets of aluminum honeycomb panels are mainly made of high-quality 3003-H18 or 3004-H18 alloy aluminum with a thickness between 0.1mm and 2.0mm.

Aluminum Honeycomb Core: Parameter

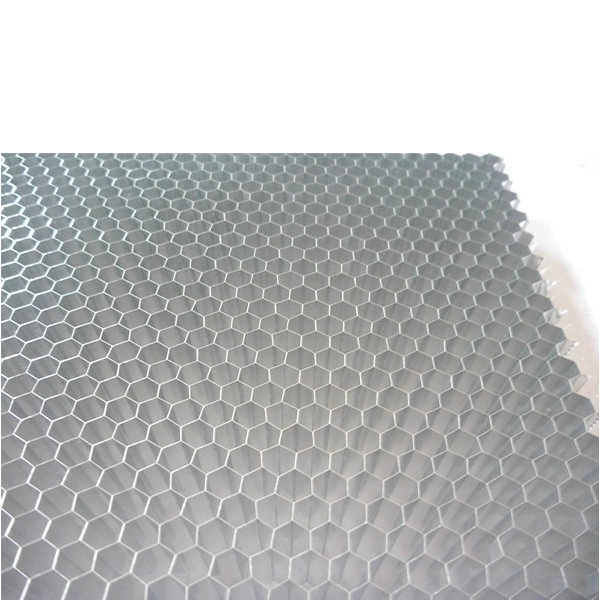

The aluminum honeycomb core is a hexagonal honeycomb core made of 3003 aluminum foil. The thickness of the aluminum foil is 0.02 ~ 0.2mm. The side lengths of the aluminum honeycomb are 5mm, 6mm, 8mm, 10mm, 12mm, etc.

Honeycomb aluminum foil thickness (mm): 0.04, 0.05, 0.06, 0.07.0.08.0.1, etc.

Performance Advantages

High flatness of the board surface and good board shape

Equipped with a board shape controller to monitor the board shape in real time. Subsequent straightening process, secondary correction of the board shape; ensure that the aluminum foil has a good board shape, high flatness of the board surface, and good board shape accuracy.

High strength and not easy to deform after processing

Using 3003-h18 / 3004-h18 aluminum foil as the aluminum foil substrate for the honeycomb core, the strength is much higher than 1100 aluminum foil, the finished product is not easy to deform, the end face is flat, the edge has no burrs, and the board surface is high after gluing and laminating.

The surface is cleanly degreased and the glue does not fall off

Special degreasing equipment uses imported cleaning fluid to ensure that the aluminum foil surface is free of oil and dirt, the glue is firmly bonded, not easy to fall off, and has a long service life.

3003 Aluminum Honeycomb Core

The honeycomb core is made of multiple layers of aluminum foil bonded together and then unfolded into a regular honeycomb shape. The factors that affect the performance of the honeycomb core mainly include parameters such as aluminum foil, node glue, and honeycomb core specifications. Aluminum foil is the most important material, and its performance has a great impact on the quality and service life of the honeycomb core.

| Alloy | 3003 Foil |

| Temper | O,H14,H16,H18,H22,H24 |

| Thickness(mm) | 0.016-0.2 |

| Width(mm) | 100-1600 |

| Length(mm) | C |

| Usage | Electronic Foil |

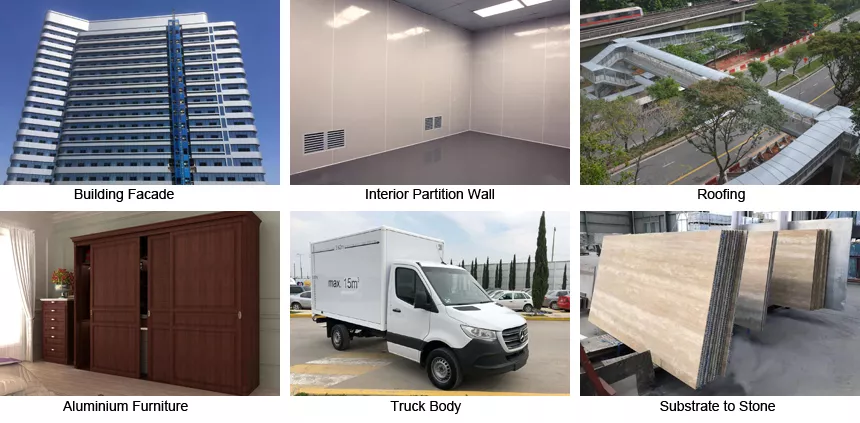

Applications

- Building exterior wall decoration, interior wall decoration, ceiling, interior partition and other construction uses.

- Cruise ship interior partition, truck compartment wall panel.

- Lightweight composite material substrate, such as stone honeycomb panel substrate, solar panel backplane, etc.

- Aluminum furniture such as wardrobes, tables and doors, because aluminum is moisture-proof and termite-proof.