Orange peel embossed aluminum sheets are specialized aluminum sheets with a surface texture that resembles the skin of an orange. This unique appearance, combined with excellent performance characteristics, makes them widely used in various fields. This article provides an in-depth look at the properties, manufacturing process, and applications of orange peel embossed aluminum sheets.

Characteristics of Orange Peel Embossed Aluminum Sheets

Orange peel embossed aluminum sheets possess several key characteristics:

Unique Appearance: The surface has a uniform orange peel pattern, which is not only aesthetically pleasing but also provides a distinctive texture.

Anti-Slip Performance: The textured pattern increases friction, giving the sheets good anti-slip properties, ideal for applications requiring slip resistance.

Corrosion Resistance: Aluminum inherently has good corrosion resistance. The embossing process enhances its oxidation and corrosion resistance further.

Good Workability: These sheets have excellent formability and can be easily cut, bent, and stamped, making them versatile for various manufacturing processes.

Lightweight: Aluminum’s low density allows for lightweight structures, improving construction efficiency and reducing overall weight.

Manufacturing Process of Orange Peel Embossed Aluminum Sheets

The production process of orange peel embossed aluminum sheets includes the following steps:

Material Selection: High-quality aluminum coils are chosen as the raw material. Commonly used aluminum alloys include 1050, 1060, 3003, and 5052.

Embossing: Specialized embossing equipment is used to create the orange peel pattern on the aluminum sheet surface, resulting in a uniform texture.

Surface Treatment: Depending on customer requirements, surface treatments such as anodizing, electrophoresis coating, and painting can be applied to enhance corrosion resistance and decorative appeal.

Cutting and Processing: The embossed aluminum coils are cut to the required sizes and further processed according to specific application needs.

Applications of Orange Peel Embossed Aluminum Sheets

Due to their unique properties and attractive appearance, orange peel embossed aluminum sheets are widely used in various industries:

Building Decoration: These sheets are often used for exterior walls, interior decoration, and ceilings in buildings. They provide an attractive appearance and offer anti-slip and anti-stain benefits.

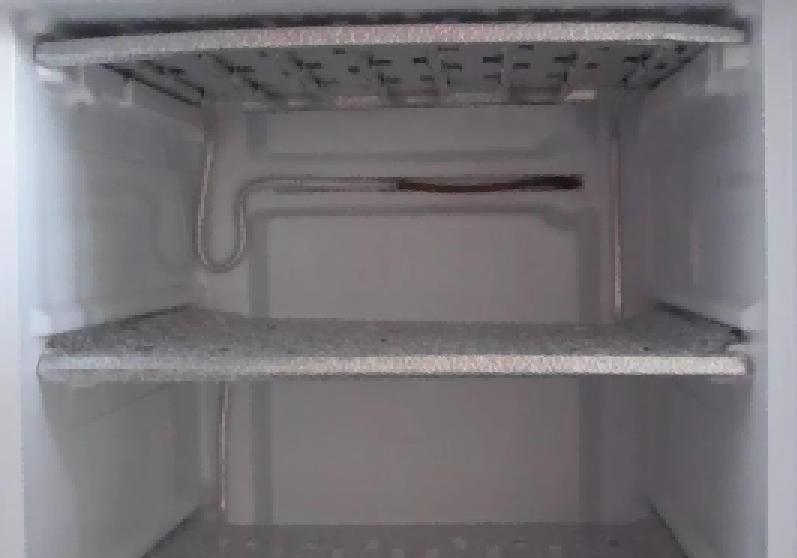

Refrigeration Equipment: In refrigeration equipment such as refrigerated trucks, cold storage units, and air conditioners, these sheets are used for inner walls and outer casings. Their good thermal conductivity and corrosion resistance improve refrigeration efficiency and equipment longevity.

Home Appliance Manufacturing: Orange peel embossed aluminum sheets are extensively used in the outer casings of refrigerators, washing machines, and microwaves. Their aesthetic appeal and corrosion resistance are highly valued by consumers.

Transportation: In vehicles like cars and trains, these sheets are used for flooring and tread plates. Their anti-slip properties and lightweight nature are significant advantages.

Industrial Applications: In the industrial sector, these sheets are used for equipment casings, workbench surfaces, and machine guards, providing excellent anti-slip effects and durability.

Conclusion

Orange peel embossed aluminum sheets, with their distinctive texture, appealing appearance, and superior performance, are widely used in building decoration, refrigeration equipment, home appliance manufacturing, transportation, and industrial applications. As manufacturing processes continue to advance and market demand increases, the application prospects for orange peel embossed aluminum sheets will become even broader.