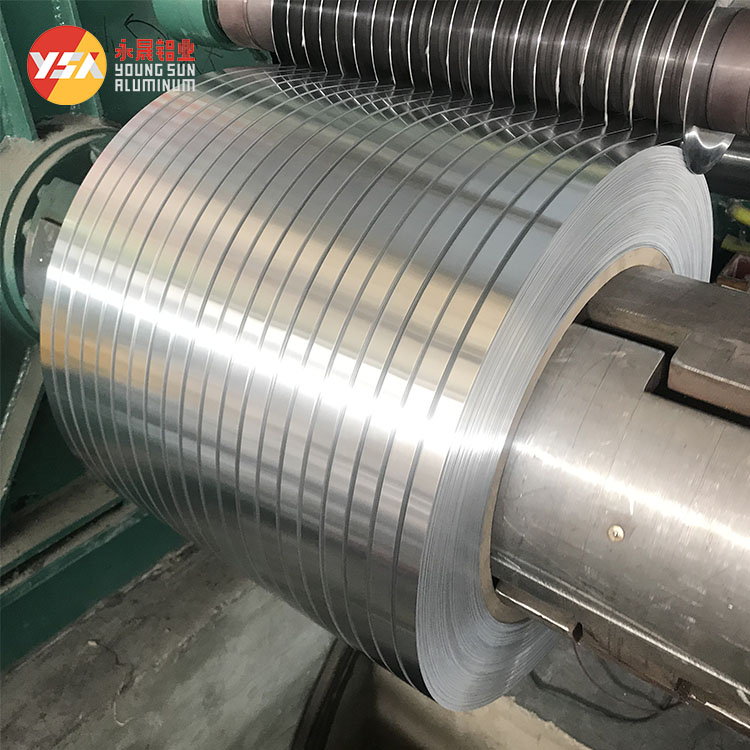

Aluminum strips play a crucial role in the hardware stamping industry due to their excellent properties and wide range of applications. This article explores the specific uses and advantages of aluminum strips in hardware stamping.

Characteristics of Aluminum Strips

1. Lightweight and High Strength: Aluminum strips have a low density but high strength and rigidity, making them suitable for hardware products that require lightweight and high-strength materials.

2. Excellent Conductivity: Aluminum has good electrical and thermal conductivity, making it ideal for manufacturing electrical and electronic products.

3. Corrosion Resistance: Aluminum strips form a dense oxide layer on their surface, providing strong resistance to oxidation and corrosion, suitable for hardware used in outdoor and humid environments.

4. Good Workability: Aluminum strips have good ductility and plasticity, making them easy to stamp, bend, and weld.

Specific Applications of Aluminum Strips in Hardware Stamping

1. Electronic Components: Aluminum strips are widely used in the manufacturing of electronic components such as heat sinks, shielding covers, and capacitor shells. The excellent thermal conductivity of aluminum makes it an ideal material for heat sinks, while its lightweight property helps reduce the overall weight of electronic products.

2. Automotive Parts: In the automotive industry, aluminum strips are used to produce lightweight structural components such as engine hoods, doors, and roofs. Aluminum strips help reduce vehicle weight, improve fuel efficiency, and lower emissions.

3. Household Appliances: Many parts of household appliances like refrigerators, washing machines, and air conditioners are made from aluminum strips. Their corrosion resistance and excellent workability make aluminum strips the preferred material for appliance hardware.

4. Building Hardware: Aluminum strips are widely used in building hardware such as window frames, door frames, and decorative metal pieces. Their excellent weather resistance and attractive appearance make them popular in architectural decoration.

5. Packaging Industry: In the packaging industry, aluminum strips are used to manufacture food containers, pharmaceutical packaging, and cosmetic packaging. The non-toxic and recyclable nature of aluminum makes it the preferred material for eco-friendly packaging.

Advantages of Aluminum Strips in Hardware Stamping

1. Cost Reduction: Aluminum strip materials have relatively low costs and good processing performance, which can reduce processing steps and time, thereby reducing production costs.

2. Product Quality Improvement: Aluminum strips have good mechanical properties and surface quality, which can improve the overall quality and appearance of stamped hardware parts.

3. Environmental Friendliness: Aluminum materials can be recycled and reused, meeting modern society’s requirements for environmental protection and sustainable development. Hardware made from aluminum strips can reduce environmental impact.

4. Efficient Production: The good workability and consistency of aluminum strips provide the advantage of efficient production in stamping processing. The waste produced during processing can also be recycled and reused, further improving production efficiency and resource utilization.

Future Prospects

With the continuous advancement of technology and the improvement of aluminum material processing technology, the application prospects of aluminum strips in hardware stamping will become broader. The development and application of new alloy aluminum strips will further enhance their mechanical properties and functionality, meeting higher requirements in various application scenarios. Additionally, with increased awareness of environmental protection and the demand for lightweight materials, the application of aluminum strips in various industries will continue to expand, providing new momentum for the development of the hardware stamping industry.

Conclusion

Aluminum strips, with their unique properties and diverse application fields, have become an indispensable material in the hardware stamping industry. Their widespread use in electronics, automotive, household appliances, construction, and packaging not only improves product quality and production efficiency but also meets the requirements for environmental protection and sustainable development. In the future, with technological advancements and changing market demands, the application of aluminum strips in hardware stamping will become more extensive and in-depth.