Non-coated aluminum foil

Non-coated aluminum foil is a rolled foil annealed without any form of treatment. China 10 years ago, foreign about 15 years ago for air conditioning heat exchange sheet of aluminum foil are non-coated foil. Even at present, about 50% of the heat exchanger tablets used in foreign developed countries are still non-coated foil, while in China, this rate is about 60%.

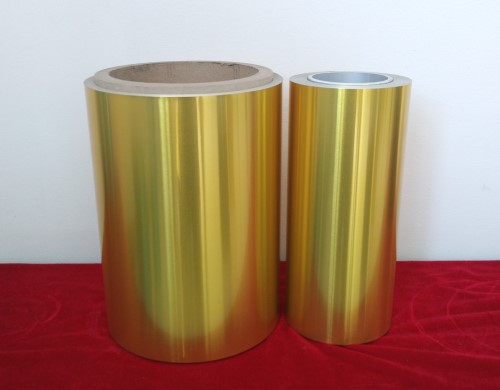

Coated aluminum foil

The so-called coated aluminum foil is the surface retreatment of non-coated foil, so that it has some special function. In Japan, Germany and other countries with rapid technology development, the use of coated foil has been used for more than 15 years. In China, the use of coated foil is no more than 10 years.

Corrosion resistant aluminum foil

The surface of corrosion-resistant aluminum foil products has a certain corrosion-resistant protective layer, and the air conditioning heat exchanger made of this product can be suitable for relatively harsh areas, and can significantly improve the service life of air conditioning. At the same time, due to the improvement of the corrosion resistance of the heat exchanger sheet, the formation of the surface corrosion powder is greatly reduced, so as to improve the ventilation quality and purify the air in the air conditioning room.

Hydrophilic aluminum foil

Hydrophilic aluminum foil surface has a strong hydrophilic properties. The quality of the hydrophilic energy is determined by the Angle formed by the water sticking to the surface of the foil. The smaller the A is, the better the hydrophilic ability, and the worse the hydrophilic energy. Generally, angle A is less than 35. That is, it belongs to the hydrophilic energy. Hydrophilic foil is generally used in air-conditioning condensers. Its main function is to make the water in the hot air in the heat transfer sheet condensation into water beads when easy to spread out and flow down along the sheet material. In this way, the ventilation effect of the heat exchanger can be affected by the water drop “bridge” between the heat exchanger, so as to improve the heat exchange rate of the air conditioning, and can save electricity under the condition of the same refrigeration capacity. At present, the general hydrophilic foil on the market has a good hydrophilic surface, but also has a high corrosion resistance, so that the performance of air conditioning is more optimized.

Hydrophobic aluminum foil

Hydrophobic aluminum foil is also called waterborne aluminum foil, its surface properties and the opposite of hydrophilic aluminum foil. That is, when the condensation water condenses to the surface of the foil, the contact Angle formed with the aluminum foil is larger, generally in 75. more than. The larger the Angle, the better the water performance. The ultimate purpose of using the hydrophobic aluminum foil is the same as the hydrophilic foil, that is, to keep the condensate water stored between the heat exchanger sheets. The difference is that the hydrophobica foil is to increase the contact Angle between the condensate water and the heat transfer sheet, so that the condensate water is easy to slide down to achieve the purpose of removing the condensate water between the heat transfer sheet.

Self-lubricating aluminum foil

Air conditioning heat exchanger in the process of processing generally to add lubricating oil on its surface, and then flush the edge, and finally wash the lubricating oil with trichloroethylene. Because trichloroethylene is harmful to human body, so in order to reduce this process, self-lubricating foil is produced accordingly. Self-lubricated foil, as the name suggests, does not need to add lubricating oil separately, and the lubrication during flushing is borne by the film of foil surface. Because there is no need to add special lubricating oil, so it also saves the subsequent trichloroethylene cleaning and drying process.

Anti-mildew aluminum foil

Anti-mildew foil is mainly used in the empty indoor unit part, its main function is to prevent the heat exchange sheet from producing surface moldy when used or placed for a long time, so as to significantly improve the ventilation quality of empty air, prevent the production of abnormal smell, and effectively improve the indoor environment of air conditioning.