Introduction

Aluminum strips, while versatile and widely used, are susceptible to various defects during production, processing, and utilization. Recognizing and effectively addressing these defects is essential to maintain the quality and performance of aluminum strips. This article will discuss the common defects in aluminum strips and provide insights into how to mitigate them effectively.

Surface Defects

Burrs: Burrs are residual rough edges on the surface of aluminum strips caused by cutting processes. They can affect appearance and safety.

Dents: Surface dents may occur due to material imperfections or processing issues, impacting aesthetics and flatness.

Oxidation: Oxidation layers on the surface of aluminum strips can diminish aesthetics and corrosion resistance.

Scratches: Surface scratches may occur during transportation, processing, or usage, affecting appearance and surface quality.

Dimensional Deviations

Thickness Deviation: Deviations in thickness affect the mechanical and processing properties of aluminum strips.

Width Deviation: Variations in width affect the fit and usability of aluminum strips.

Length Deviation: Differences in length can impact application and processing.

Internal Defects

Pores: Internal pores reduce the strength and sealability of aluminum strips.

Inclusions: Impurities or foreign particles may infiltrate the interior of aluminum strips, affecting uniformity and performance.

Crystal Defects: Defects in the crystal structure of aluminum strips affect mechanical and processing properties.

Mechanical Performance Defects

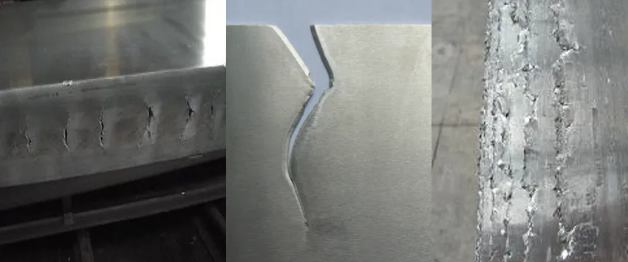

Bending Deformation: Aluminum strips may undergo bending deformation during transportation or processing, affecting usability and fit.

Cracks: Cracks in aluminum strips reduce strength and durability.

Fatigue Fracture: Prolonged usage or frequent deformation may lead to fatigue fracture, impacting safety and reliability.

Other Defects

Raw Material Issues: Quality problems in the raw materials of aluminum strips, such as inadequate chemical composition or excessive impurities, affect overall quality and performance.

Surface Coating Problems: If aluminum strips undergo surface coating treatment, issues like poor adhesion or uneven coating may result in defects.

Conclusion

In conclusion, aluminum strips may exhibit various defects stemming from factors such as production, processing, transportation, and usage. Prompt identification and resolution of these defects are crucial to ensuring the quality and performance of aluminum strips. By addressing these defects effectively, manufacturers and users can optimize the usability and reliability of aluminum strips in various applications.